Double-medium rotary treatment device for organic waste gas purification

A technology for organic waste gas and treatment devices, applied in gas treatment, chemical instruments and methods, membrane technology, etc., can solve problems such as increased operating costs, frequent replacement of activated carbon, increased loading and unloading, transportation, replacement and other working procedures, and achieves reduced operating costs. cost, improve tight isolation, and improve the effect of adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

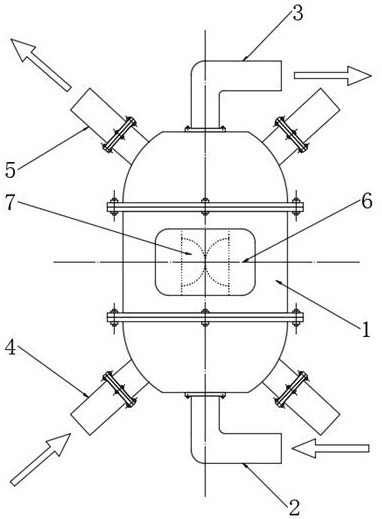

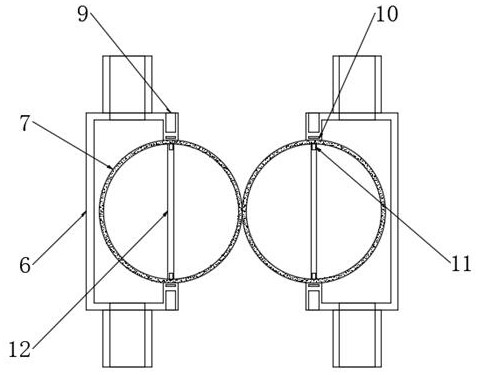

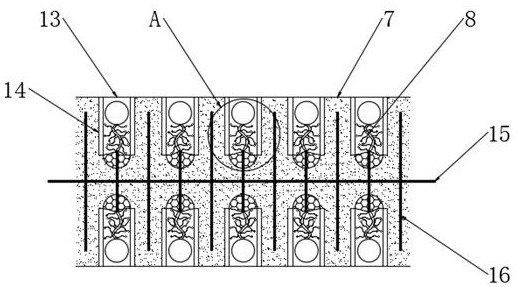

Embodiment 1

[0044] see Figure 1-2 , a dual-media rotary treatment device for organic waste gas purification, comprising a filter tower 1, the upper and lower ends of the filter tower 1 are respectively fixedly connected with an outlet pipe 3 and an inlet pipe 2, and the side walls of the upper and lower ends of the filter tower 1 are respectively fixedly connected There are a pair of recovery pipes 5 and desorption pipes 4, and a pair of horizontally symmetrical rotary boxes 6 are fixedly installed in the filter tower 1, and both the desorption pipes 4 and the recovery pipes 5 run through the filter tower 1 and extend into the filter tower 1 to connect with the rotary box 6, A pair of revolving boxes 6 are provided with a revolving hole at one end close to each other, and a matching activated carbon fiber adsorption cylinder 7 is arranged in the revolving hole. 7 connection, the upper and lower side walls of the rotary hole are inlaid with semiconductor refrigeration chips 10, and the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com