Energy-saving environment-friendly electrified boiler

An energy-saving and environmentally friendly boiler technology, which is applied to steam boilers, steam boiler accessories, steam boiler components, etc., to achieve the effects of low cost, easy promotion, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

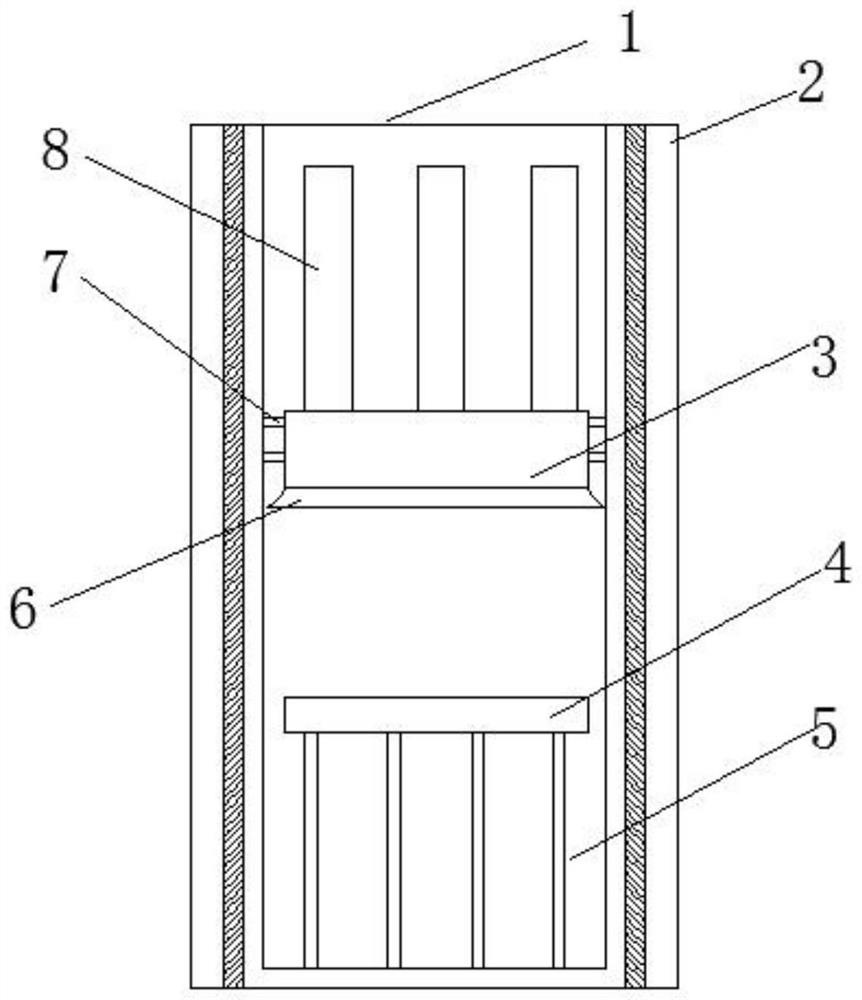

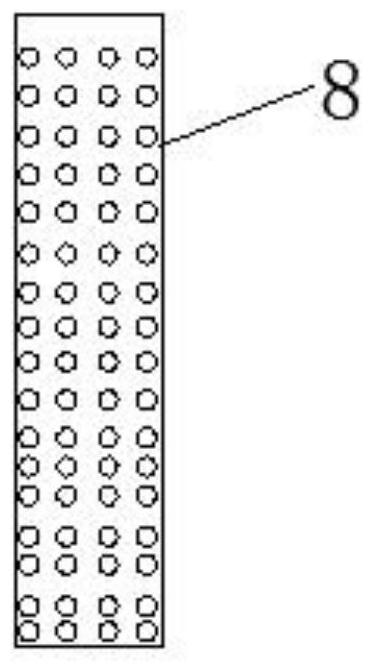

[0023] refer to Figure 1-4 , an energy-saving and environmentally friendly electrified boiler, comprising a boiler body 1, an insulation layer 2 is arranged outside the shell of the boiler body 1, a hot runner device 3 is fixed to the inner cavity of the boiler body 1 through a first bracket 7, and the bottom of the hot runner device 3 is welded There is a heat collecting device 6 , a heat pipe 8 is welded above the hot runner device 3 , and the bottom of the inner cavity of the boiler body 1 is fixed with a combustion head 4 through a second bracket 5 .

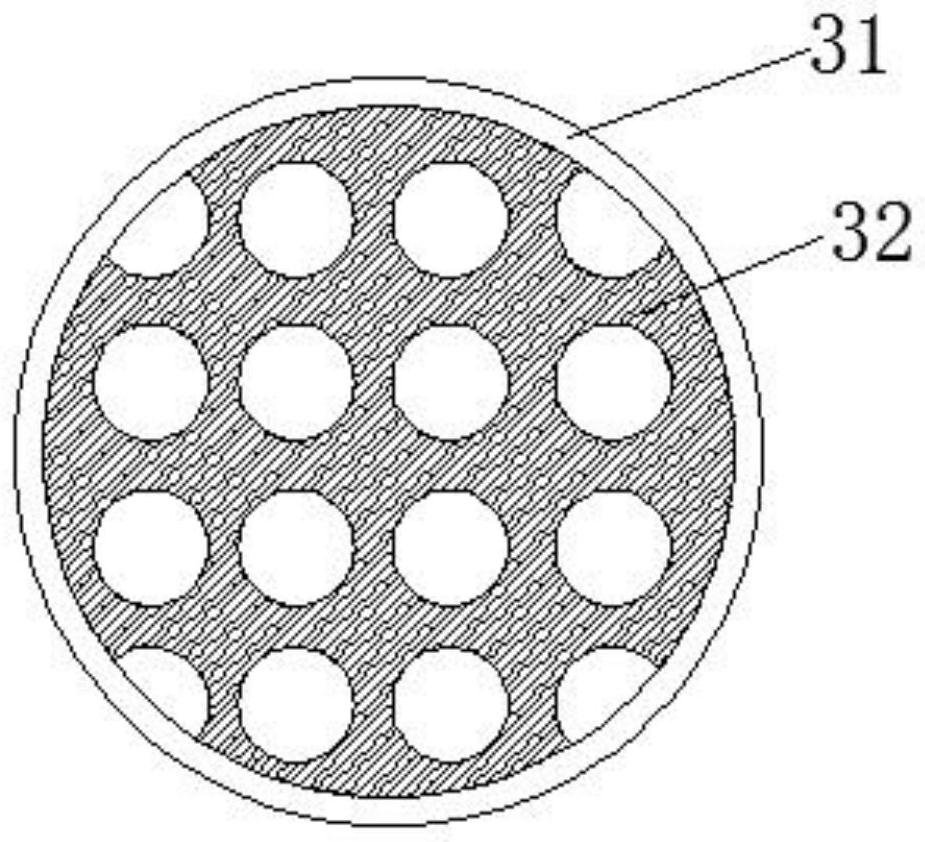

[0024] The hot runner device 3 includes a housing 31 and a partition 32, the partition 32 has a through hole, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com