Photo-thermal micro-thruster based on annular core capillary optical fiber

A micro-propeller and capillary technology, which is applied in the components, instruments, optics and other directions of pumping devices for elastic fluids, can solve the problems of unused and optical-thermal effect characteristics of optical fibers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

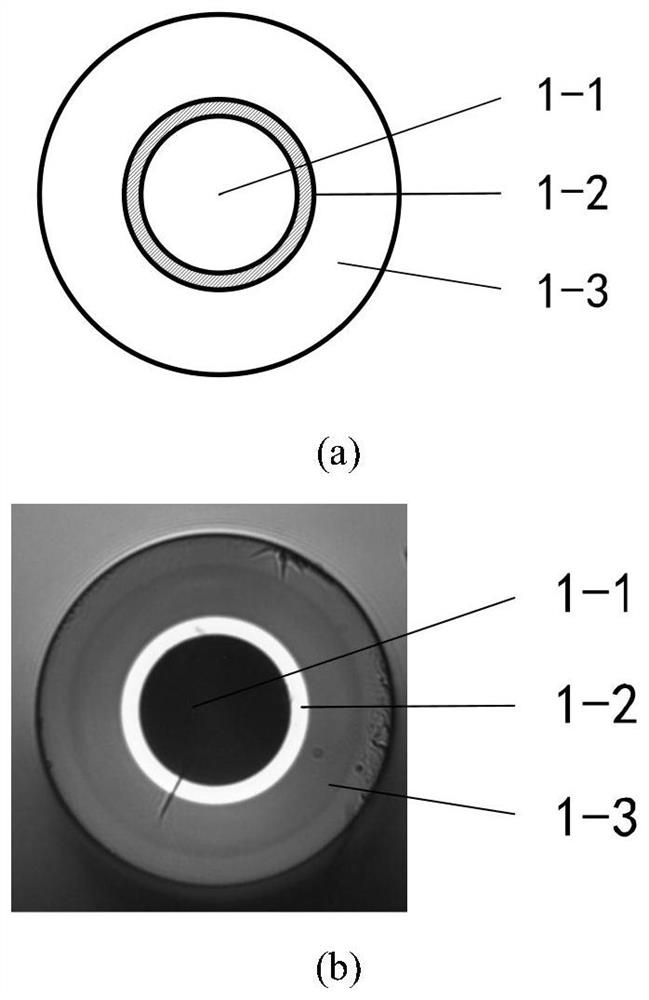

[0052] figure 1 Shown is a cross-sectional view of a capillary fiber consisting of a thin layer, an annular core with a refractive index slightly higher than that of the cladding material, and an air hole structure that allows access to microfluidics.

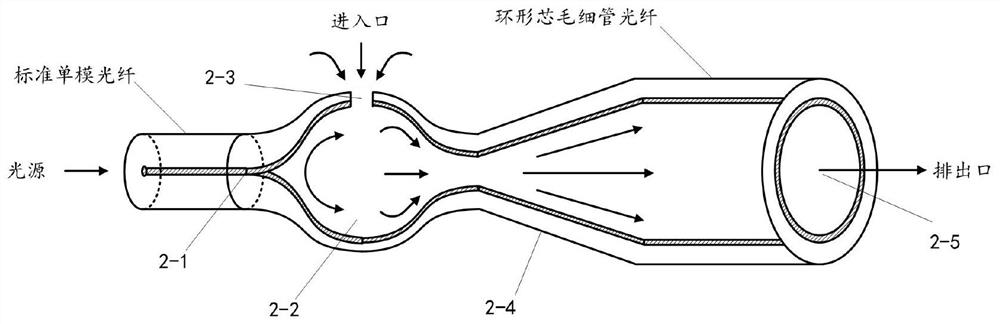

[0053] figure 2 It shows that the ring-core capillary fiber is processed into a jet pump-like structure, wherein one end of the ring-shaped fiber core is melted and shrunk by heating until the capillary pores of the fiber are sealed to form a solid optical wave channel 2-1, thus becoming Optical interface for interconnection with external light sources. After one end is sealed, a nearly spherical heating chamber 2-2 is prepared by means of air pressurization and heating, and a microfluidic liquid microhole is prepared as a liquid inlet 2-3 by using femtosecond drilling processing technology o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com