Anti-freeze-thaw water-based terrace and construction method thereof

A freeze-thaw-resistant and floor-resistant technology, used in metal-free paints, cellulose coatings, building structures, etc., can solve problems such as floor deformation, floor surface damage, melting, etc., achieving low cost and improved use. performance, the effect of improving crack resistance and impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

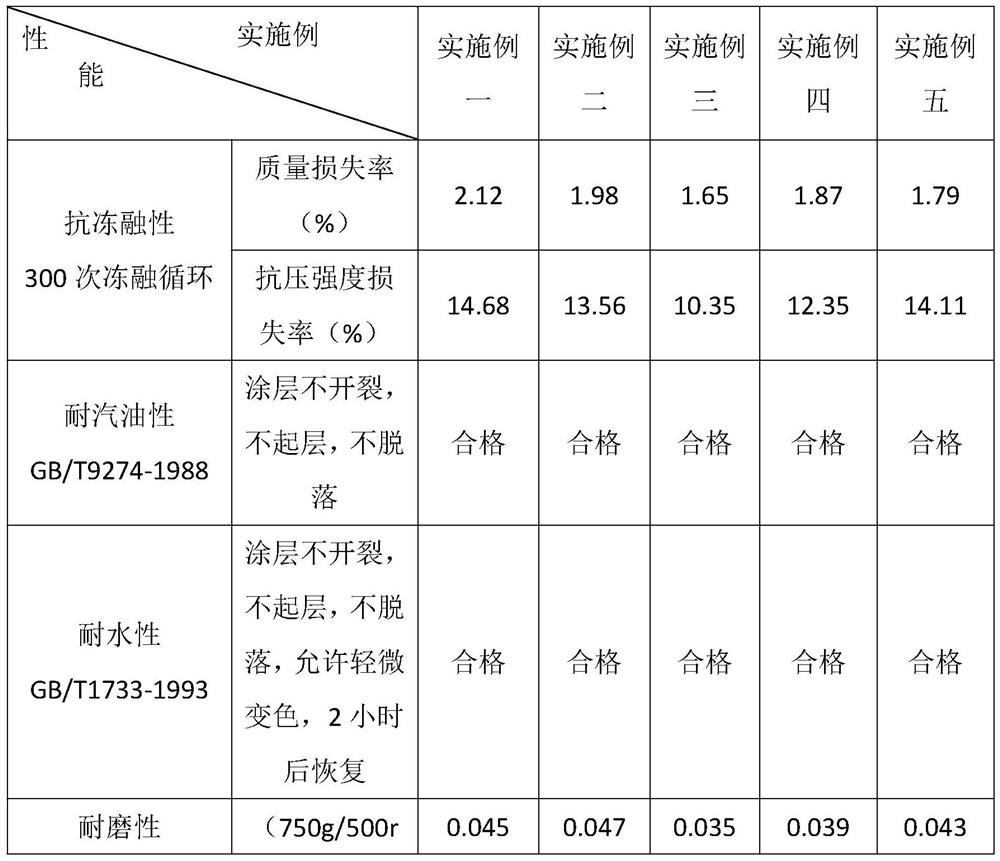

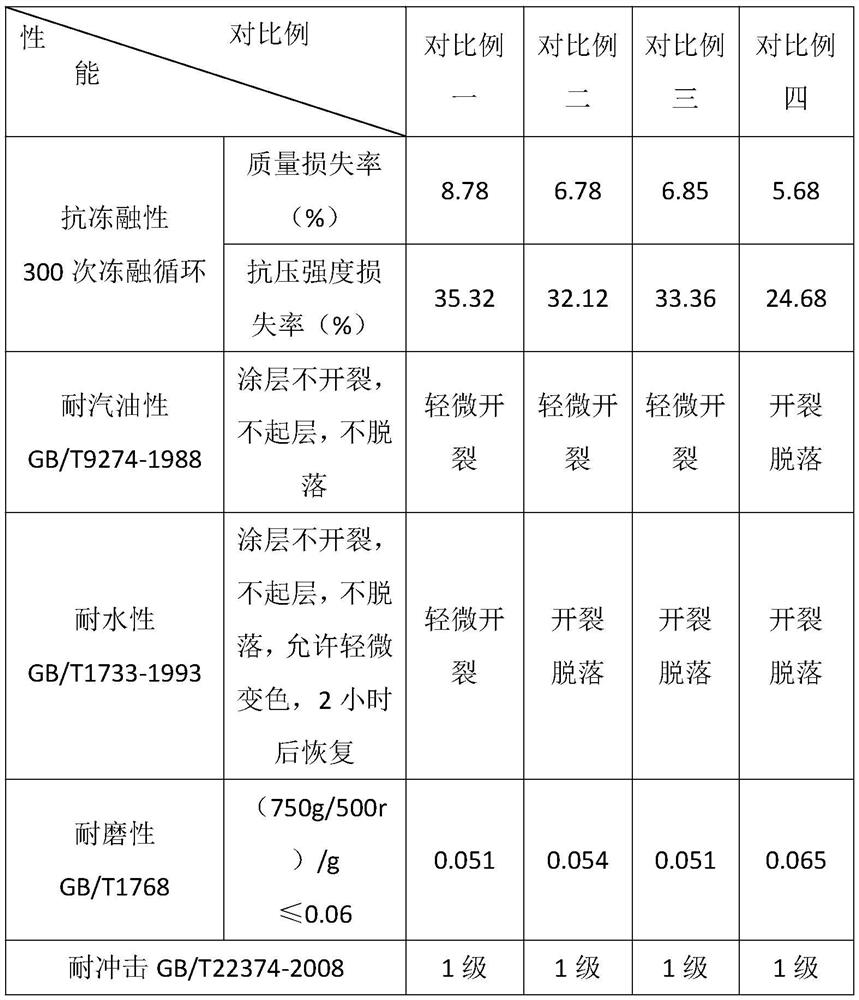

Examples

Embodiment 1

[0038] The invention discloses a freeze-thaw resistant water-based floor, which comprises a concrete floor base and a freeze-thaw resistant layer arranged on the concrete floor base. The raw materials of the freeze-thaw layer include the following components by weight: 57 parts of siloxane , 36 parts of modified silane, 61 parts of water-based varnish, 20 parts of polypropylene glycol diglycidyl ether, 20 parts of o-cresyl glycidyl ether, 25 parts of calcium oxide, 19 parts of volcanic ash, 30 parts of (100 mesh) carbon fiber, ( 90 orders) 25 parts of ramie fibers, 18 parts of fillers, 25 parts of antioxidants.

[0039] The filler includes the following components in parts by weight: 25 parts of polydimethylsiloxane, 22 parts of hydrogenated nitrile rubber, and 15 parts of foamed aluminum powder.

[0040] The water-based glazing oil comprises the following components in parts by weight: 42 parts of water-soluble acrylic resin, 30 parts of water, 6 parts of vinyl bis-stearamide...

Embodiment 2

[0051] The invention discloses a freeze-thaw resistant water-based floor, which comprises a concrete floor base and a freeze-thaw resistant layer arranged on the concrete floor base. The raw materials of the freeze-thaw layer include the following components by weight: 60 parts of siloxane , 40 parts of modified silane, 60 parts of water-based varnish, 22 parts of polypropylene glycol diglycidyl ether, 18 parts of o-cresyl glycidyl ether, 28 parts of calcium oxide, 21 parts of volcanic ash, 28 parts of (110 mesh) carbon fiber, ( 120 orders) 29 parts of ramie fibers, 22 parts of fillers, 23 parts of antioxidants.

[0052] The filler includes the following components in parts by weight: 28 parts of polydimethylsiloxane, 20 parts of hydrogenated nitrile rubber, and 18 parts of foamed aluminum powder.

[0053] The water-based glazing oil comprises the following components in parts by weight: 40 parts of water-soluble acrylic resin, 33 parts of water, 5 parts of vinyl bis-stearamid...

Embodiment 3

[0064] The invention discloses a freeze-thaw-resistant water-based floor, which comprises a concrete floor base and a freeze-thaw-resistant layer arranged on the concrete floor base. The raw materials of the freeze-thaw layer include the following components by weight: 67 parts of siloxane , 40 parts of modified silane, 65 parts of water-based varnish, 28 parts of polypropylene glycol diglycidyl ether, 20 parts of o-cresyl glycidyl ether, 32 parts of calcium oxide, 30 parts of volcanic ash, 36 parts of (150 mesh) carbon fiber, ( 160 orders) 29 parts of ramie fibers, 26 parts of fillers, 25 parts of antioxidants.

[0065] The filler includes the following components in parts by weight: 30 parts of polydimethylsiloxane, 26 parts of hydrogenated nitrile rubber, and 19 parts of foamed aluminum powder.

[0066] The water-based glazing oil comprises the following components in parts by weight: 54 parts of water-soluble acrylic resin, 59 parts of water, 7 parts of vinyl bis-stearamid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com