Polycrystalline cubic boron nitride composite sheet and preparation method and application thereof

A cubic boron nitride and polycrystalline cubic technology, applied in the field of polycrystalline cubic boron nitride composite sheet and its preparation, can solve the problems of poor hardness and strength, unsuitable PCBN, easy chipping and damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

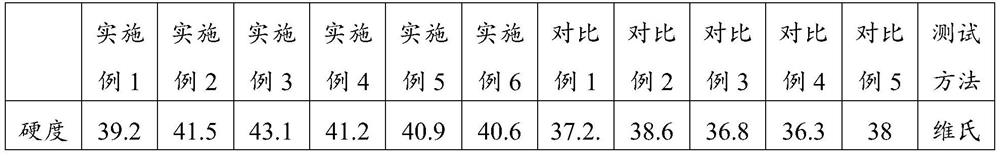

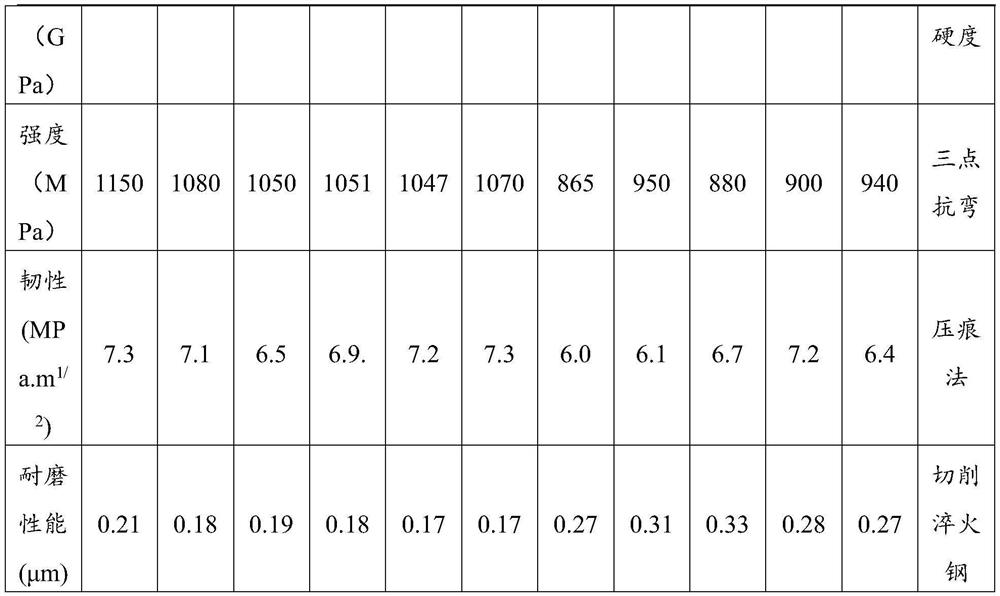

Examples

preparation example Construction

[0029] The present invention also provides a method for preparing the polycrystalline cubic boron nitride composite sheet described in the above technical solution, comprising the following steps:

[0030] Mix tungsten-titanium solid solution, nano-alumina, sintering aid and cubic boron nitride to obtain a mixed material;

[0031] The mixed material is sequentially subjected to vacuum heat treatment and high temperature and high pressure sintering to obtain the polycrystalline cubic boron nitride composite sheet.

[0032] The invention mixes tungsten-titanium solid solution, nano-alumina, sintering aid and cubic boron nitride to obtain a mixed material.

[0033]In the present invention, the mixing order of the tungsten-titanium solid solution, nano-alumina, sintering aid and cubic boron nitride is preferably: first mix the tungsten-titanium solid solution, nano-alumina and sintering aid to obtain the first mixture Afterwards, the first mixture is mixed with cubic boron nitrid...

Embodiment 1

[0042] Configure 70 parts of CBN, 8 parts of nano-alumina, 18 parts of tungsten-titanium solid solution (the mass ratio of tungsten element to titanium element is 1:1) and 4 parts of aluminum nitride;

[0043] Among them, the average particle size of CBN is 1-3 μm; the average particle size of tungsten-titanium solid solution is 4 μm; the average particle size of nano-alumina is 200 nm; the average particle size of aluminum nitride is 2 μm.

[0044] The tungsten-titanium solid solution, nano-alumina and aluminum nitride are ball-milled on a ball mill, and ethanol is added as a dispersion medium. The ball-to-material ratio of ball milling is 5:1, and the speed is 300r / min. After ball milling for 4 hours, CBN is added, and the speed is 200r / min. After ball milling for 4 hours, dry at 80°C for 12 hours, and pass through a 100-mesh sieve after drying to obtain a mixed material.

[0045] Put the mixed material into a circular metal cup, at a temperature of 1050°C and a vacuum of 10...

Embodiment 2

[0049] Configure 80 parts of CBN, 5 parts of nano-alumina, 13 parts of tungsten-titanium solid solution (the mass ratio of tungsten element to titanium element is 1:1) and 2 parts of aluminum nitride;

[0050] Among them, the average particle size of CBN is 1-3 μm; the average particle size of tungsten-titanium solid solution is 4 μm; the average particle size of nano-alumina is 200 nm; the average particle size of aluminum nitride is 2 μm.

[0051] Mill tungsten-titanium solid solution, nano-alumina and aluminum nitride on a ball mill, add ethanol as a dispersion medium, the ball-to-material ratio of ball milling is 5:1, and the speed is 300r / min. After 4 hours, add CBN, and the speed is 200r / min. After 4 hours, dry at 80°C for 12 hours, and pass through a 100-mesh sieve after drying to obtain a mixed material.

[0052] Put the mixed material into a circular metal cup, at a temperature of 1050°C and a vacuum of 10 -2 Under Pa condition, carry out vacuum treatment to mixed ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com