Organ-shaped degradable bag and preparation method thereof

An organ-shaped, raw material technology, applied in the field of packaging, can solve problems such as harmful gases to the human body and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

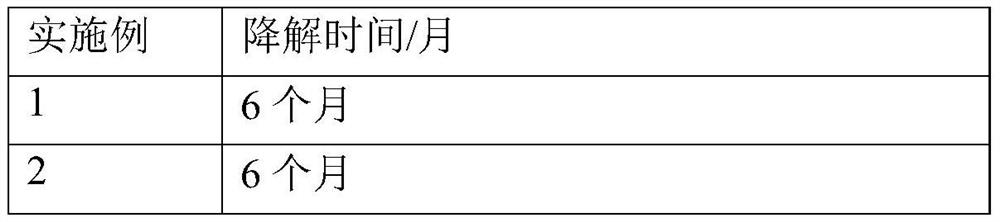

Examples

Embodiment 1

[0031] An organ-shaped biodegradable bag, including eight sides, prepared by using the following raw materials in parts by weight: 10 parts, 30 parts of straw pulp fiber, 10 parts of sweet potato flour, 10 parts, 30 parts, 25 parts of cassava flour and melaleuca tree 70 parts of skin fiber and 10 parts of scallop powder, oyster shell powder, conch shell powder, bagasse powder, polylactic acid; the main body of the organ-shaped degradable bag is mainly composed of the first base material and the second base material from outside to inside. Synthesized with the third base material, the first base material is kraft paper, the second base material and the third base material are both PLA; the two sides of the accordion-shaped degradable bag are folded.

[0032] The preparation method of the accordion-shaped degradable bag of the present embodiment comprises the following steps:

[0033] (S1) Weighing raw materials: weighing raw materials according to the ratio of parts by weight; ...

Embodiment 2

[0047] An organ-shaped biodegradable bag, including eight sides, prepared by using the following raw materials in parts by weight: 15 parts, 40 parts of straw pulp fiber, 30 parts of sweet potato flour, 18 parts, 45 parts, 35 parts of cassava flour and melaleuca tree Skin fiber 120 parts and scallop powder, oyster shell powder, conch shell powder, bagasse powder, polylactic acid and 10 parts. The main body of the organ-shaped degradable bag is composed of two layers of kraft paper and PLA from the outside to the inside; the two sides of the organ-shaped degradable bag are folded.

[0048] The preparation method of the accordion-shaped degradable bag of the present embodiment comprises the following steps:

[0049] (S1) Weighing raw materials: weighing raw materials according to the ratio of parts by weight;

[0050] (S2) Prepare the first mixed liquid material: firstly mix the wheat straw pulp fiber, sweet potato flour, tapioca flour, parts and melaleuca bark fiber evenly, an...

Embodiment 3

[0062] An organ-shaped biodegradable bag, including eight sides, prepared from the following raw materials by weight: 20 parts, 60 parts of straw pulp fiber, 50 parts of sweet potato flour, 20, 50 parts, 40 parts of cassava flour and melaleuca 150 parts of bark fiber and 10 parts of scallop powder, oyster shell powder, conch shell powder, bagasse powder, and polylactic acid. The main body of the organ-shaped degradable bag is composed of PLA-PLA from the outside to the inside; the two sides of the organ-shaped degradable bag are folded.

[0063] The preparation method of the accordion-shaped degradable bag of the present embodiment comprises the following steps:

[0064] (S1) Weighing raw materials: weighing raw materials according to the ratio of parts by weight;

[0065] (S2) Prepare the first mixed liquid material: firstly mix the wheat straw pulp fiber, sweet potato flour, tapioca flour, parts and melaleuca bark fiber evenly, and dilute with water to prepare the first mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com