Efficient washing device for generating high-speed spinning liquid drops based on composite wet surface

A washing device and droplet technology, which is applied to the washing machine/rinsing machine of tableware, parts of washing machine/rinsing and rinsing machine of tableware, household cleaning device, etc., which can solve the problem of long cleaning time, affecting the efficiency of dishwashing, and unsatisfactory Short-term requirements and other issues, to achieve the effect of high kinetic energy and high energy conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

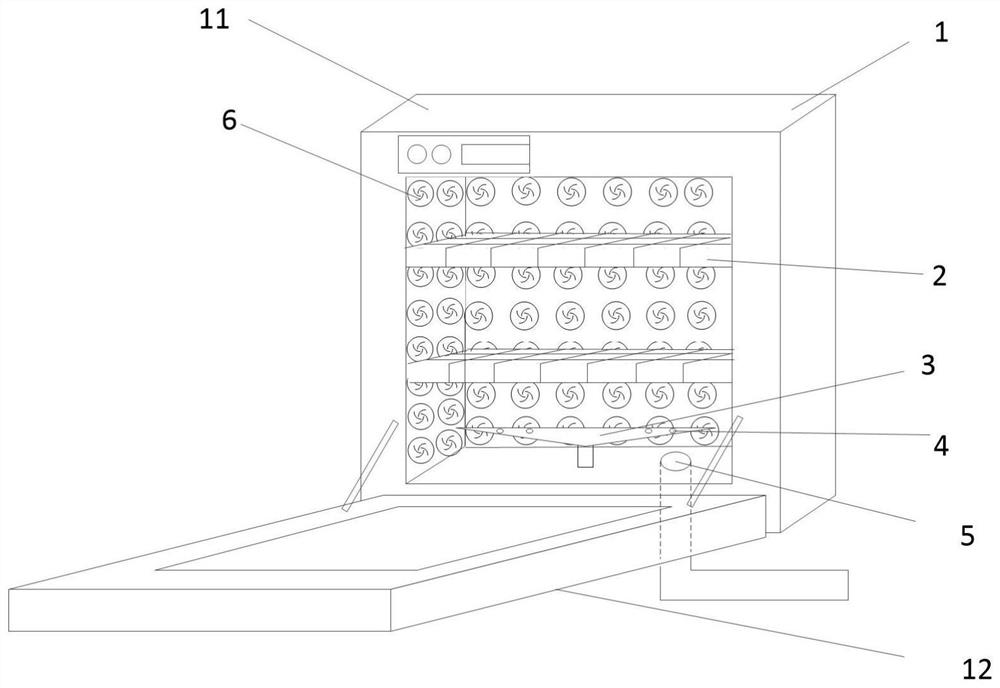

[0017] Such as figure 1 As shown, the present invention provides a high-efficiency washing device that generates high-speed spin droplets based on a composite wetting surface, including a tableware holding cabinet 1 and a control system, and the tableware holding cabinet 1 is a box that can be opened at one end Shaped structure, preferably rectangular structure. The tableware storage cabinet 1 includes a main body 11 and a cover 12 mated with the main body 11 , and the cover 12 is used to cover the opening on the main body 11 .

[0018] The inside of the body 11 is provided with a plurality of storage racks 2 and a rotating nozzle 3, the rotating nozzle 3 communicates with the external water inlet pipe 5, and is provided with a plurality of water spray holes 4 for spraying clear water (or water and detergent mixture) for washing ope...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com