Drilling and piling integrated machine

An all-in-one machine and machine body technology, which is applied in the direction of drilling equipment and methods, sheet pile walls, drilling equipment, etc., can solve the problems of low quality of drilling and piling, low efficiency of drilling and piling, etc., to prolong the continuous working time and reduce costs The effect of investment and strong carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

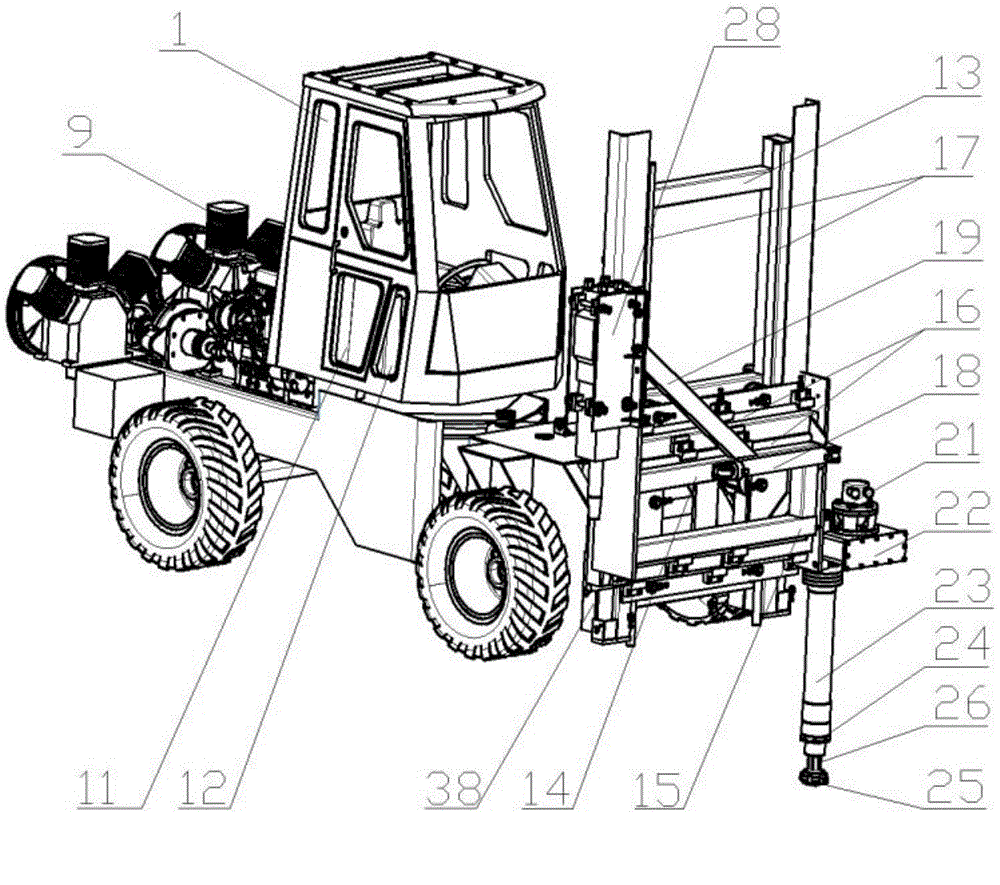

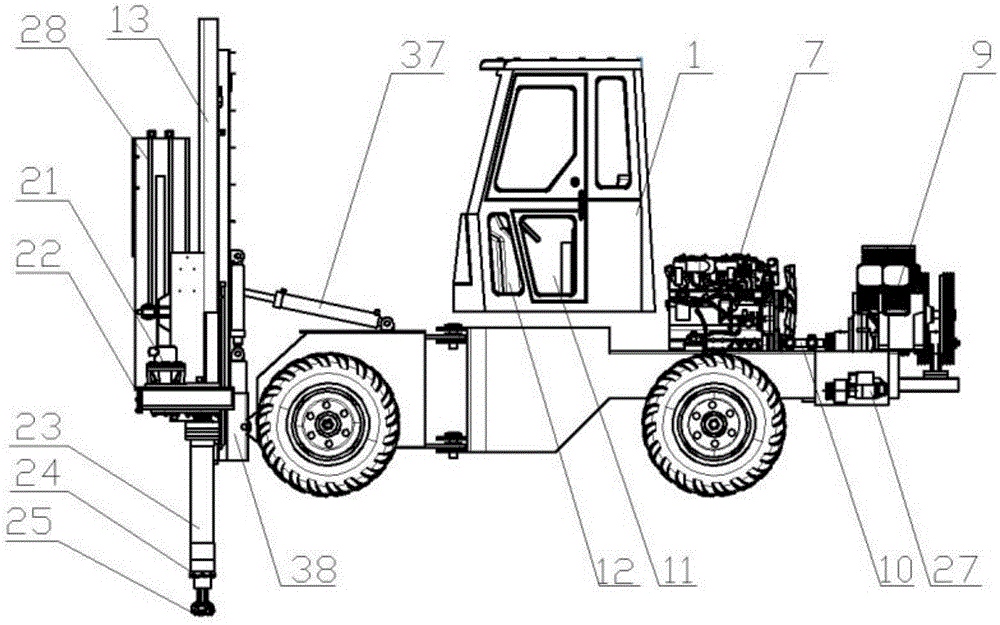

[0041]With reference to the accompanying drawings, the drilling and piling integrated machine provided by the present invention includes a cab 1, a body carrying system, a power system, and a hydraulic control system. The body carrying system includes a vehicle frame device, a front axle 2, and a rear axle 3. The vehicle frame device includes Front frame 4, rear frame 5, front frame 4, rear frame 5 are connected by hinge device 6, ensure that the front and rear ends of the drilling and piling integrated machine are flexibly connected together, the front frame 4, rear frame 5 A steering oil cylinder 42 for controlling the left and right swing of the hinge of the front frame 4 is arranged near the hinge device 6 between them. Turning the oil cylinder 42 enables the integrated drilling and piling machine to move in different directions. The front axle 2 and the rear axle 3 are two end is connected with two wheels respectively, rear vehicle frame 5 tops are provided with working su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com