Automatic glue dispensing device for imaging lens

A technology of automatic glue dispensing and imaging lens, which is applied to the surface coating liquid device, pretreatment surface, coating and other directions, which can solve the problems of difficult to guarantee product consistency, increase manufacturing cost, and low product quality, and achieve saving Labor costs, increased productivity, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

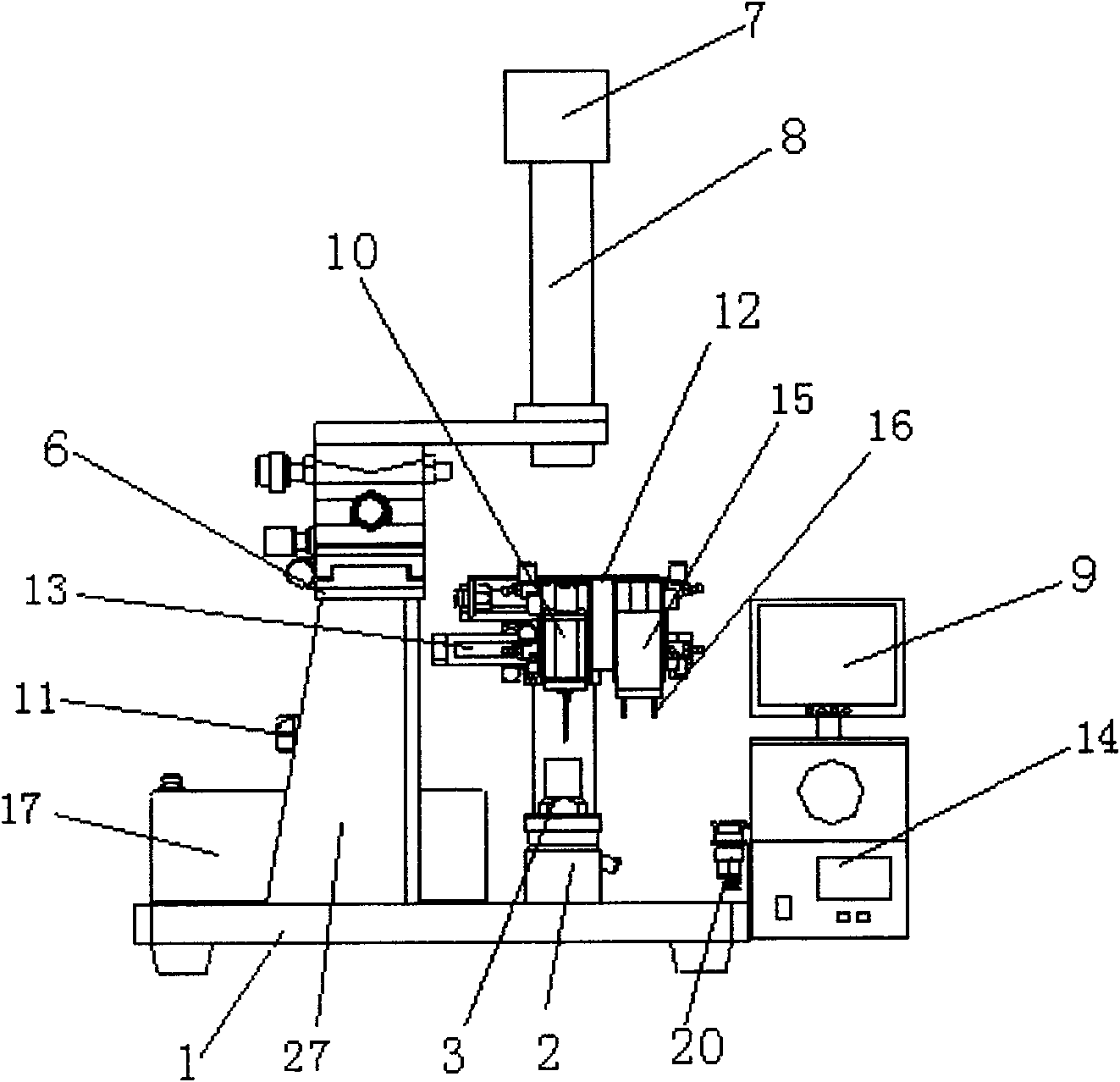

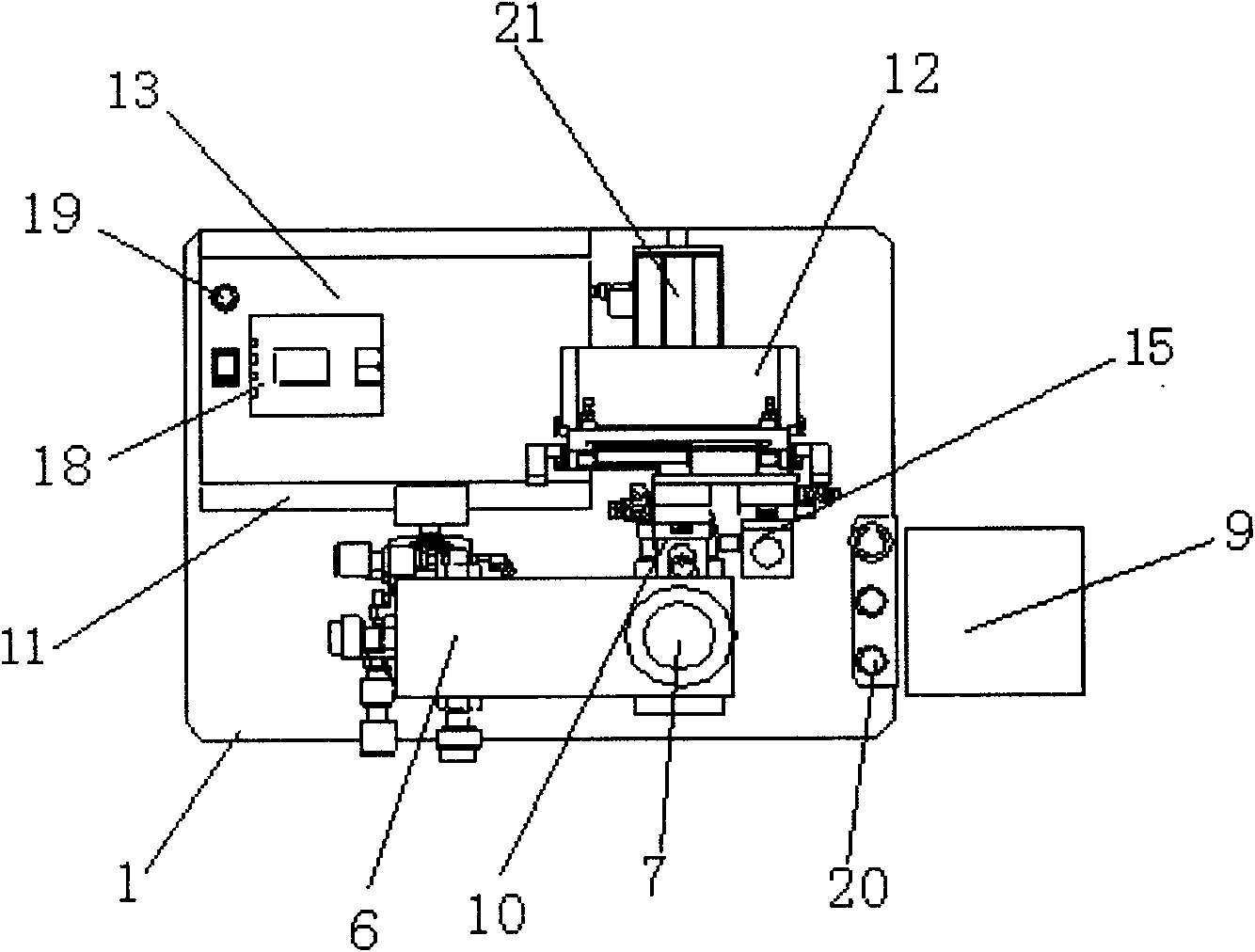

[0029] Example 1, such as figure 1 As shown, an automatic glue dispensing device for an imaging lens is characterized in that: it comprises a workpiece positioning device, a workpiece detection device, a glue dispensing device, a glue curing device and a control system arranged on a workbench 1,

[0030] Such as figure 1 As shown, the described workpiece positioning device is used to fix the workpiece carrier; it includes a positioning platform 2 and an adapted positioning positioning column 3, the described positioning platform 2 is a plane, and the surface of the positioning platform 2 is provided with a positioning hole 4 and a positioning Corresponding to the connecting body 5 arranged at the lower part of the column 3;

[0031] Such as figure 1 As shown, the workpiece detection device is used to detect that the optical axis of the lens is parallel to the axis of the lens barrel; it includes an adjustment frame 6 arranged on the workbench 1, a CCD7 is arranged at one end...

Embodiment 2

[0038] Embodiment 2 is on the basis of embodiment 1, as image 3 As shown, in order to make the positioning of the workpiece stable and easy to replace, the positioning hole 4 in the workpiece positioning device is a screw hole, and the connecting body 5 of the positioning column 3 is a stud.

Embodiment 3

[0039] Embodiment 3 On the basis of Embodiment 1, in order to fit the workpiece, the positioning column 3 is either circular or square.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com