Molded fuel and method for producing same

A manufacturing method and technology of fuel, applied in the direction of fuel, waste fuel, biofuel, etc., can solve the problems of unstable supply, price rise, etc., and achieve the effect of excellent handling and high heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

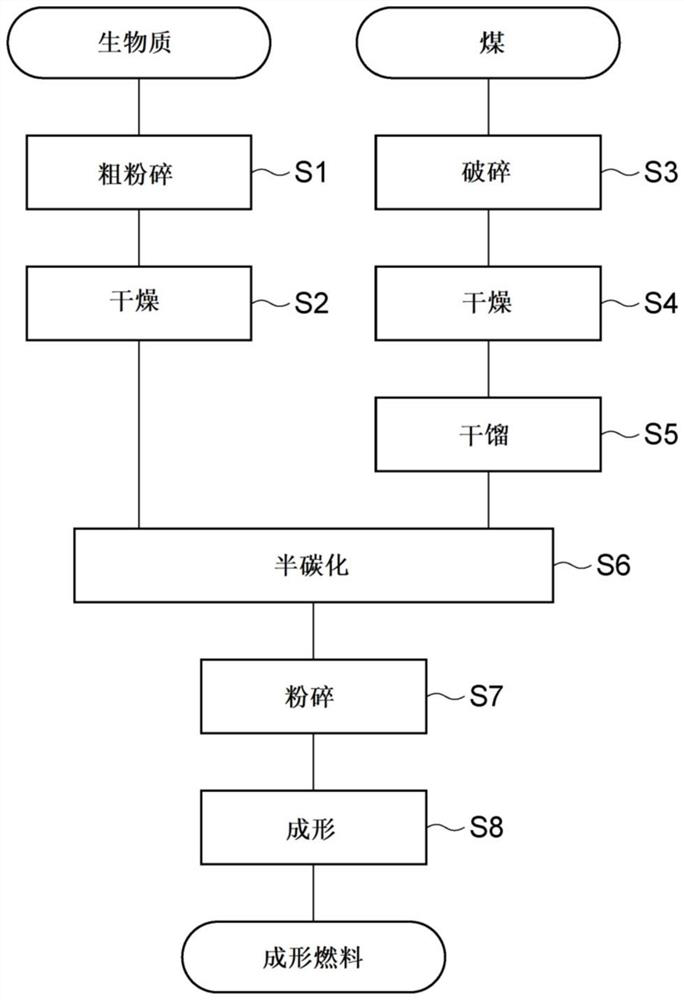

Method used

Image

Examples

Embodiment

[0108] The content of the present invention will be described in more detail with reference to the experimental results.

[0109] (preparatory experiment)

[0110] [Changes in biomass due to semi-carbonization]

[0111] Fragments of eucalyptus (particle size: 10 to 50 mm) were prepared as biomass. The biomass is heated in an oxygen-free atmosphere at a temperature of 200-400° C. for 2 hours in an electric furnace to obtain a biomass semi-carbide. Determination of industrial analysis, elemental analysis and high-level calorific value of biomass before semi-carbonization and biomass semi-carbides obtained by semi-carbonization at various semi-carbonization temperatures. The results are shown in Table 2.

[0112] [Table 2]

[0113]

[0114] Figure 4 The dry basis calorific value (high calorific value) of the biomass semi-carbides shown in Table 2 is marked in . From these results, it was confirmed that the calorific value can be increased by semi-carbonizing the biomass...

experiment example 1

[0117] The biomass semi-carbides (semi-carbonization temperature: 320° C.) shown in Table 2 were mixed with carbonized coal obtained by carbonizing coal at 480° C. for 60 minutes to obtain a mixture. Regarding the mixing ratio, 30 parts by mass of the biomass semi-carbide and 70 parts by mass of the pyrolysis coal were used with respect to 100 parts by mass of the total of the biomass semi-carbide and pyrolysis coal. The average particle size of biomass semi-carbide and dry distillation coal is 0.2mm. The mixture was mixed with an aqueous solution (aqueous binder solution) containing commercially available polyvinyl alcohol (saponification degree: >99.85 mol%, polymerization degree: 1700) at a concentration of 10% by mass and water to obtain a molding material. The compounding ratio at this time was varied in the range of 10-40 mass parts (1-4 mass parts as binder) of binder aqueous solution with respect to 100 mass parts of mixtures, and various molding raw materials were pre...

experiment example 2

[0124] The biomass semi-carbide (320° C.) shown in Table 2 was mixed with carbonized coal obtained by carbonizing coal at 480° C. for 60 minutes to obtain a mixture. Regarding the mixing ratio, 50 parts by mass of the biomass semi-carbide and 50 parts by mass of the pyrolysis coal were used with respect to 100 parts by mass of the total of the biomass semi-carbide and pyrolysis coal.

[0125] The mixture was heated at a temperature of 180° C. for 60 minutes in an atmosphere having an oxygen concentration of 5% by volume. This oxidation treatment step was performed to obtain a mixture (mixed fuel) (pyrolysis coal:biomass semi-carbide=50 parts by mass:50 parts by mass). An oxidation calorific value measurement test (DSC test) of the produced blended fuel was performed. In this test, 10 mg of mixed fuel crushed to a size of 212 μm or less was placed in a sample container made of alumina, and the temperature of the sample was raised to 107°C in a nitrogen atmosphere. After reachi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com