Connecting device for automobile exhaust pipe

A technology for automobile exhaust and connecting devices, which is applied in the direction of exhaust devices, noise reduction devices, machines/engines, etc., which can solve the problems of inability to effectively guarantee the safety of exhaust pipes, damage and fall off of exhaust pipes, and elimination of carbon dioxide, so as to avoid greenhouse effect, avoiding equipment damage, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

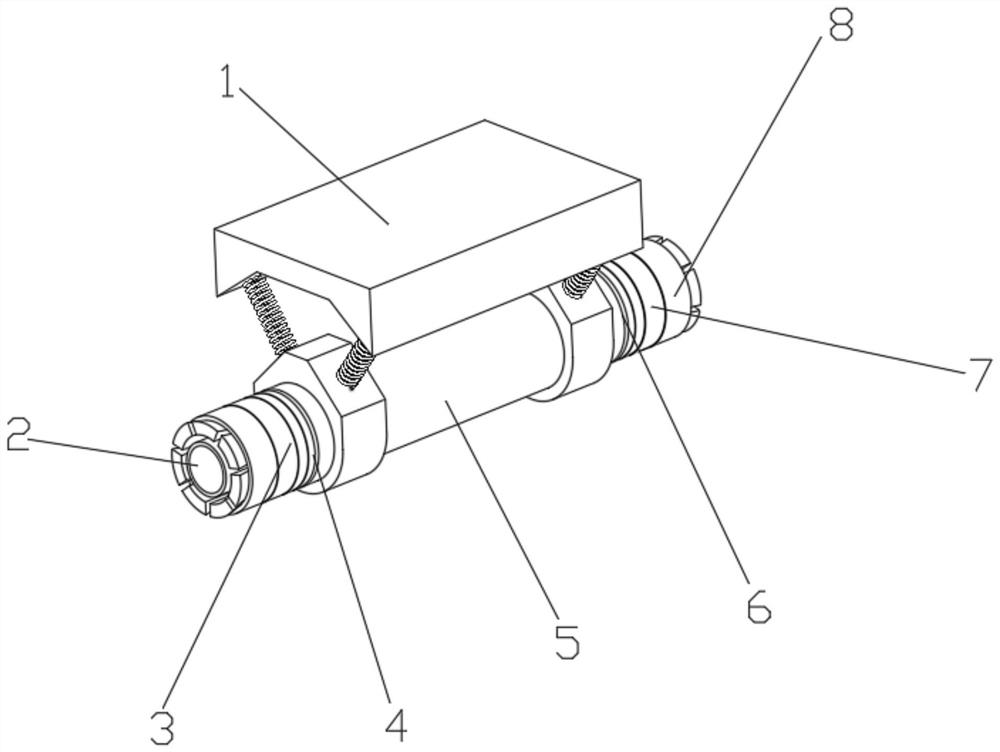

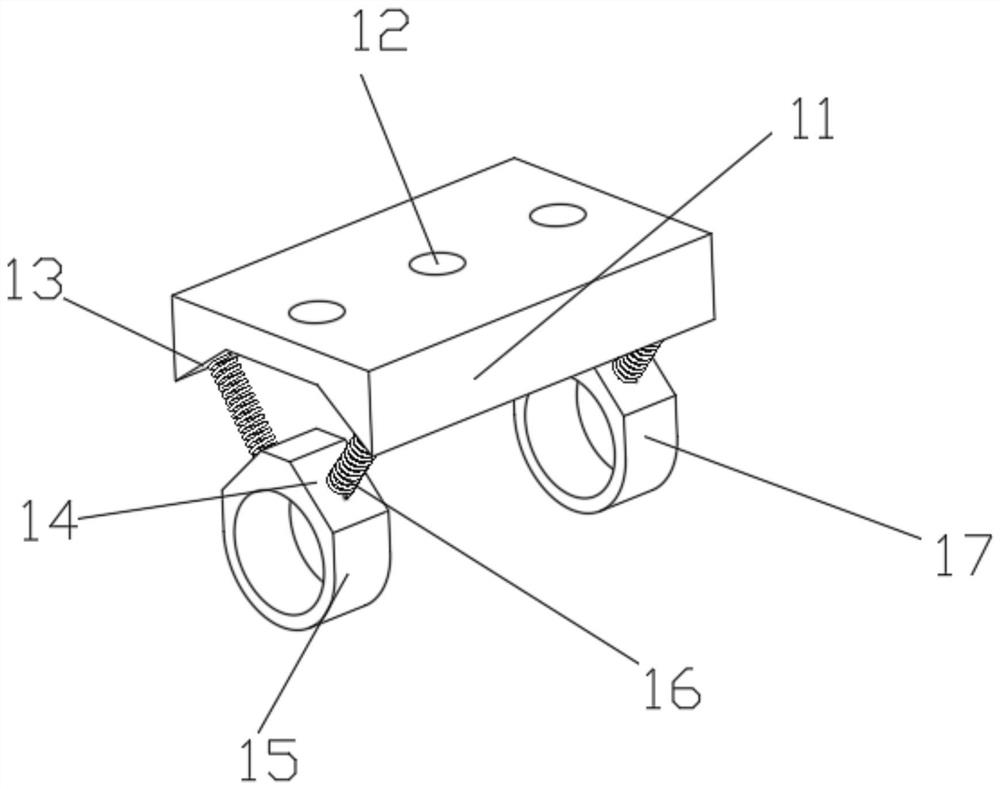

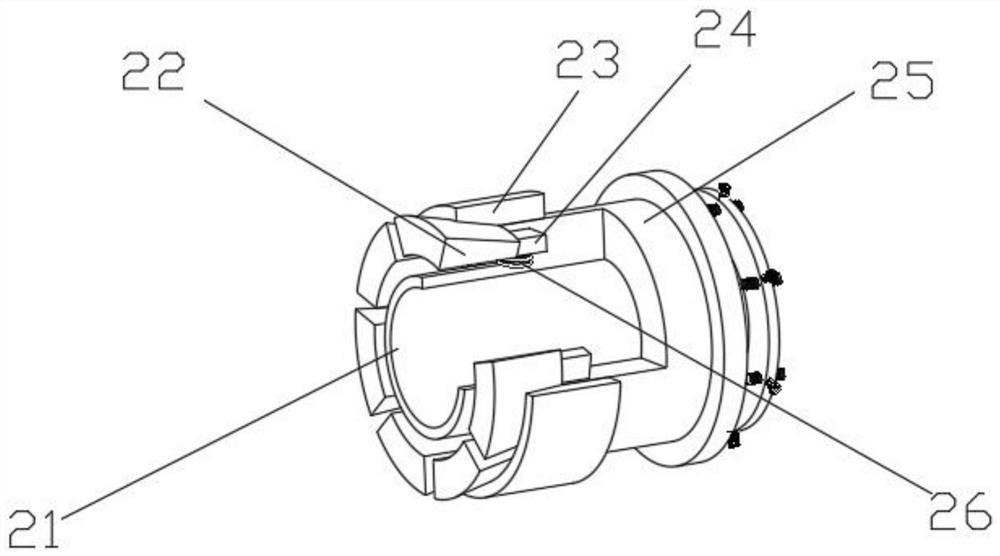

[0028] see Figure 1-7 As shown, an automobile exhaust pipe connecting device includes a connecting device fixing frame 1, a first connecting head 2, a first connecting head safety device 3, a first connecting head shock absorbing device 4, an exhaust pipe processing pipe 5, a first connecting head The second joint damping device 6, the second joint safety device 7 and the second joint 8, the first joint damping device 4 and the second joint damping device 6 are respectively fixed on the front and rear end surfaces of the exhaust pipe processing pipe 5 The head end of the first connector shock absorbing device 4 is fixedly connected with the first connector 2, the end of the second connector shock absorbing device 6 is fixedly connected with the second connector 8, and the first connector safety device 3 is rotatably fixed on the first On the outer wall of the connector damping device 4, and the first connector safety device 3 is fixedly connected to the first connector 2, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com