Tubular product rolling device

A winding device and pipe material technology, applied in the direction of transportation and packaging, conveying filamentous materials, thin material processing, etc., can solve the problems of pulling, deformation of PVC inner pipe body, and affecting the production quality of PVC reinforced hose, etc. Uniform force and high production quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in further detail below in conjunction with the accompanying drawings.

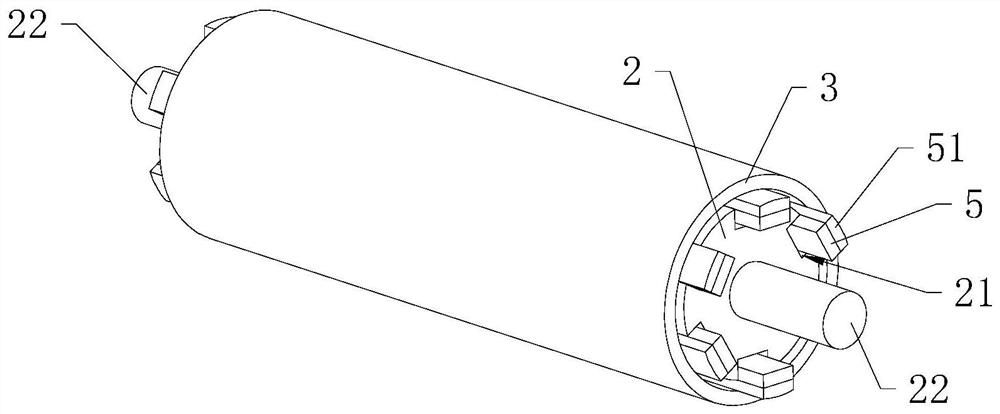

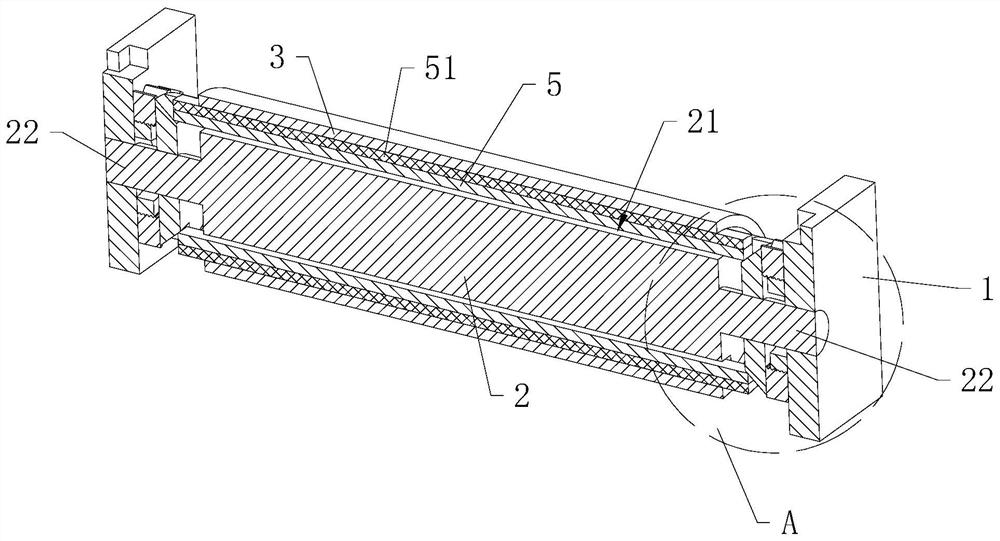

[0049] refer to figure 1 , 2 , is a pipe winding device disclosed in the present invention, comprising a frame 1, a rotating shaft 2, a sleeve 3 and a motor 4, the rotating shaft 2 is mounted on the frame 1 for rotation, and the sleeve 3 is rotatably socketed on the outer periphery of the rotating shaft 2, Moreover, a friction pair is formed between the inner circumference of the sleeve 3 and the rotating shaft 2, and the motor 4 is used to drive the rotating shaft 2 to rotate at a constant speed, and rely on the friction force between the inner circumference of the sleeve 3 and the rotating shaft 2 to drive the sleeve 3 to rotate, so as to achieve The outer periphery of the cylinder 3 is wound up with pipe material.

[0050] With the winding of the pipe, the actual winding radius of the pipe gradually increases, and the pipe hinders the rotation of the sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com