Nano silver copper wrapped welding flux preparing method based on phonochemistry

A nano-silver, sonochemical technology, applied in welding equipment, nanotechnology, welding/cutting media/materials, etc., can solve the problems of high cost of nano-silver paste, electromigration of nano-copper paste, shortening reaction time, etc., and achieve high service life Effects of temperature, increased activity and energy, and availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

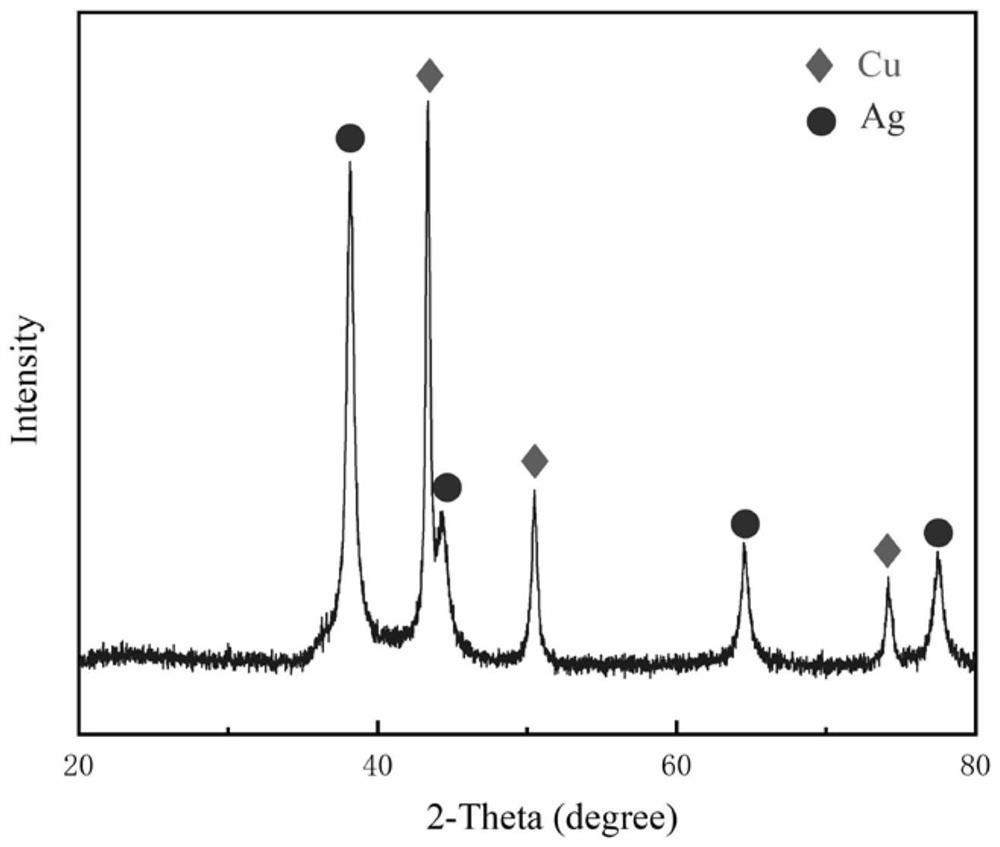

Image

Examples

Embodiment 1

[0055] (1) Weigh 10 g of copper sulfate pentahydrate powder and add it to 100 ml of ethylene glycol, heat to 70°C, stir for 15 min until completely dissolved to obtain solution A. In addition, weigh 8g of sodium hypophosphite powder, add 5g of polyvinylpyrrolidone into 200ml of ethylene glycol, heat to 70°C, stir for 20 minutes and wait for complete dissolution to obtain solution B.

[0056] (2) Add the freshly prepared solution A to the freshly prepared solution B, and apply a horn-type (horn) pulsed ultrasonic wave (power 200 W, pulse ratio 2 s-2 s) acting straight down, and heat to 70 ℃, react for 15 min, and the copper nanoparticle dispersion can be obtained.

[0057] (3) Cool the copper nanoparticle dispersion obtained in step (2) to room temperature and centrifuge (5000 rpm, 15 min), and use a mixed solution of absolute ethanol: deionized water at a volume ratio of 3:1 Wash 3 times.

[0058] (4) Weigh 2 g of Cu nanoparticles obtained in step (3) and 2 g of sodium citra...

Embodiment 2

[0064] (1) Weigh 10 g of copper sulfate pentahydrate powder and add it to 100 ml of ethylene glycol, heat to 70°C, stir for 15 min until completely dissolved to obtain solution A. In addition, weigh 8g of sodium hypophosphite powder, add 5g of polyvinylpyrrolidone into 200ml of ethylene glycol, heat to 70°C, stir for 20 minutes and wait for complete dissolution to obtain solution B.

[0065] (2) Add the freshly prepared solution A to the freshly prepared solution B, and apply a horn-type (horn) pulsed ultrasonic wave (400 W, pulse ratio of 2 s-2 s) acting directly downward, and heat to 70 °C, After 15 min of reaction, the copper nanoparticle dispersion can be obtained.

[0066] (3) Cool the copper nanoparticle dispersion obtained in step (2) to room temperature and centrifuge (5000 rpm, 15 min), and use a mixed solution of absolute ethanol: deionized water at a volume ratio of 3:1 Wash 3 times.

[0067] (4) Weigh 2 g of Cu nanoparticles obtained in step (3) and 2 g of sodium...

Embodiment 3

[0072] (1) Weigh 10 g of copper sulfate pentahydrate powder and add it to 100 ml of ethylene glycol, heat to 70°C, stir for 15 min until completely dissolved to obtain solution A. In addition, weigh 8g of sodium hypophosphite powder, add 5g of polyvinylpyrrolidone into 200ml of ethylene glycol, heat to 70°C, stir for 20 minutes and wait for complete dissolution to obtain solution B.

[0073] (2) Add the freshly prepared solution A to the freshly prepared solution B, and apply a horn-type (horn) pulsed ultrasonic wave (600 W, pulse ratio 4 s-2 s) acting straight down, and heat to 70 °C, After 15 min of reaction, the copper nanoparticle dispersion can be obtained.

[0074](3) Cool the copper nanoparticle dispersion obtained in step (2) to room temperature and centrifuge (5000 rpm, 15 min), and use a mixed solution of absolute ethanol: deionized water at a volume ratio of 3:1 Wash 3 times.

[0075] (4) Weigh 2 g of Cu nanoparticles obtained in step (3) and 2 g of sodium citrate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com