DOC catalytic coating with high fuel oil ignition performance and preparation method thereof

A catalytic coating and fuel oil technology, applied in the field of catalyst research, can solve the problems of not fully exerting the full synergistic effect of the upstream and downstream catalysts in the axial direction, not fully utilizing the active center of the catalyst, and having large differences in concentration distribution trends, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

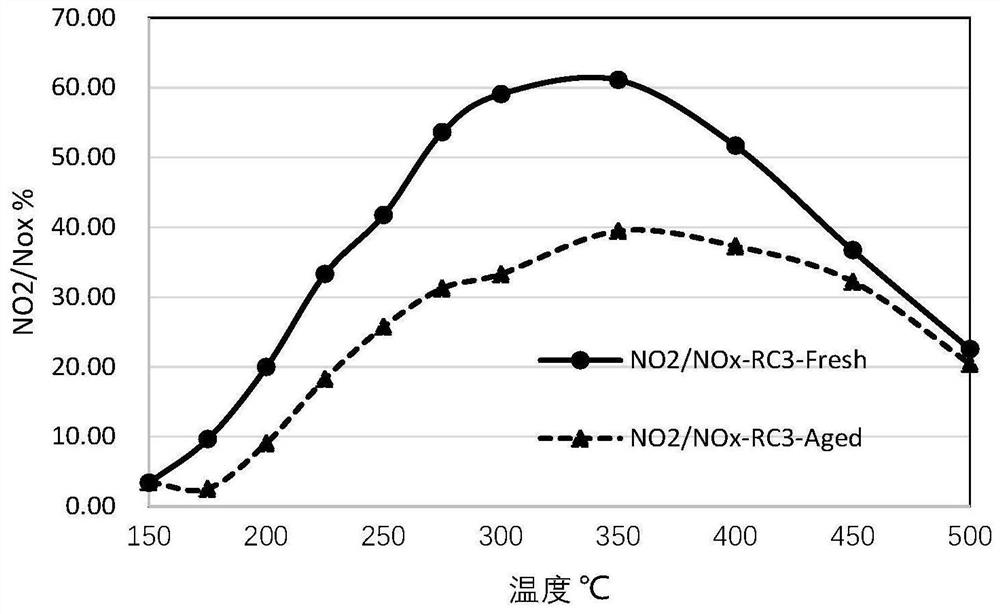

Image

Examples

preparation example Construction

[0054] The invention discloses a method for preparing a DOC catalytic coating with high fuel oil ignition performance. The catalytic coating is a bottom layer located on the surface of a permeable carrier and at least one upper layer above the surface of the bottom layer. The upper layer is divided into two parts along the flow axis of the carrier. The preparation method of the catalytic coating in the front section and the back section includes the following steps in sequence: preparation of the bottom layer, pre-preparation of the upper layer front section coating, preparation of the upper layer rear section coating, preparation of the upper layer front section precious metal gradient coating;

[0055] Among them, both the bottom layer and the upper layer back stage include the preparation, coating, and drying and roasting of noble metal and catalytic material slurry; the pre-preparation of the upper layer front layer coating includes the preparation, coating, drying and roast...

Embodiment 1

[0152] 1. Bottom catalyst preparation and coating:

[0153] (1) Weigh alumina (150m 2 / g, pore volume 0.5ml / g), cerium-zirconium composite oxide (CeO 2 50%, ZrO 2 50%, 95m 2 / g, pore volume 0.4ml / g), the weight ratio of the two catalytic materials is 1:1, the water pore volume after mixing is 100ml / 100g, a total of 998.7g;

[0154] (2) Weigh 0.975g of platinum chloride and 0.325g of palladium chloride (calculated as metal element), mix well, add deionized water, so that the total volume reaches 1000ml, and obtain the configured noble metal precursor solution;

[0155] (3) Add the prepared noble metal precursor solution into the alumina being stirred in the form of a spray, and continue to stir for 2 hours after the noble metal solution is added;

[0156] (4) stirring and drying the precious metal catalytic material in (3) at 80°C until the water content is lower than 3%;

[0157] (5) Calcining the dried noble metal catalytic material in an air atmosphere at 500° C. for ...

Embodiment 2

[0192] With example 1, change point is that step 4, does not add glucose, obtains catalyst C2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com