System capable of utilizing heat conducting oil to recycle waste heat of industrial waste gas

A technology of industrial waste gas and heat transfer oil, which is applied to clean heat transfer devices, lighting and heating equipment, cleaning methods and appliances, etc. It can solve problems such as reducing the heat conversion rate of heat exchange tubes, blocking equipment with impurities, and affecting heat exchange effects. , to achieve the effect of improving the heat transfer effect, improving the heat conversion rate, and improving the removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

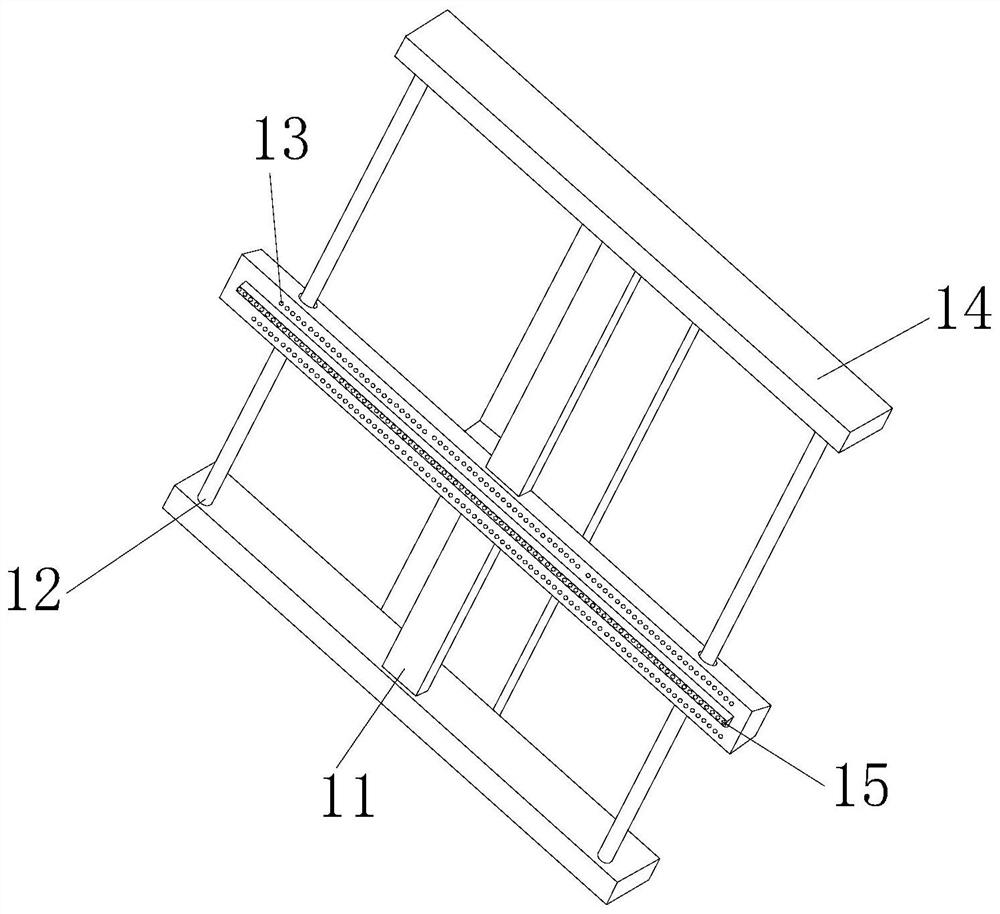

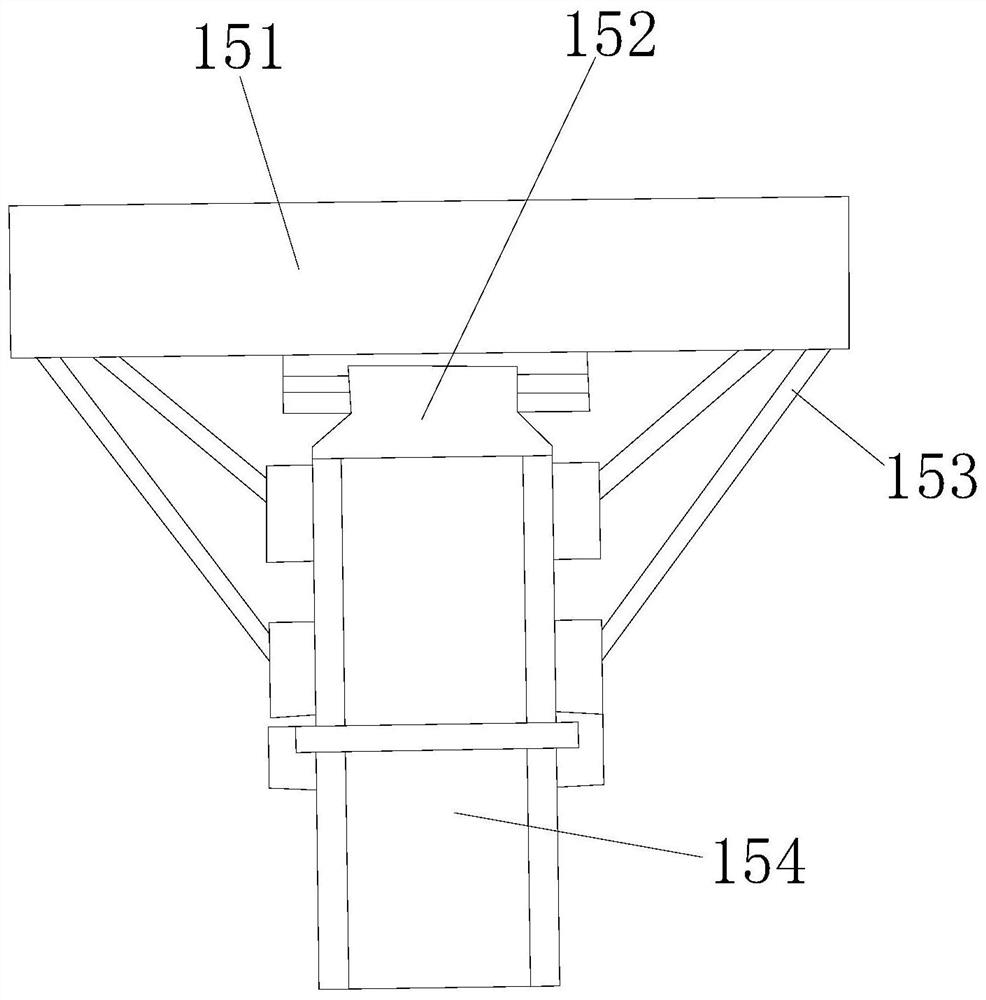

[0032] see figure 1 , the present invention provides a technical solution: a system for recovering waste heat from industrial waste gas by using heat conduction oil, the structure of which includes a soot cleaning device 1, a water inlet pipe 2, an air inlet pipe 3, a preheater 4, a heat exchanger 5, and an air blowing device 6. Outlet pipe 7, connecting pipe 8, circulation pump 9, heat collector 10, the dust removal device 1 is installed on the side of the heat collector 10, the front end of the heat collector 10 is provided with a circulation pump 9, and the circulation The pump 9 is connected through the inside of the heat collector 10, the preheater 4 is arranged at the middle position on the top of the heat collector 10, the preheater 4 is connected with the heat exchanger 5, and the heat exchanger 5 is connected to the right The air blowing device 6 is provided on the side, and the air blowing device 6 is connected to the inside of the heat collector 10, and the top of ...

Embodiment 2

[0039] see figure 1 , the present invention provides a technical solution: a system for recovering waste heat from industrial waste gas by using heat conduction oil, the structure of which includes a soot cleaning device 1, a water inlet pipe 2, an air inlet pipe 3, a preheater 4, a heat exchanger 5, and an air blowing device 6. Outlet pipe 7, connecting pipe 8, circulation pump 9, heat collector 10, the dust removal device 1 is installed on the side of the heat collector 10, the front end of the heat collector 10 is provided with a circulation pump 9, and the circulation The pump 9 is connected through the inside of the heat collector 10, the preheater 4 is arranged at the middle position on the top of the heat collector 10, the preheater 4 is connected with the heat exchanger 5, and the heat exchanger 5 is connected to the right The air blowing device 6 is provided on the side, and the air blowing device 6 is connected to the inside of the heat collector 10, and the top of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com