Method and device for installing steel sheet piles in large-diameter boulder and sandstone stratum

A steel sheet pile, large-diameter technology, applied in the direction of sheet pile wall, building, foundation structure engineering, etc., can solve the problems of inability to plant piles, low efficiency, wear of drill pipes and drill teeth, etc., to improve the implantation speed and efficiency, The effect of reducing construction safety risks and speeding up construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

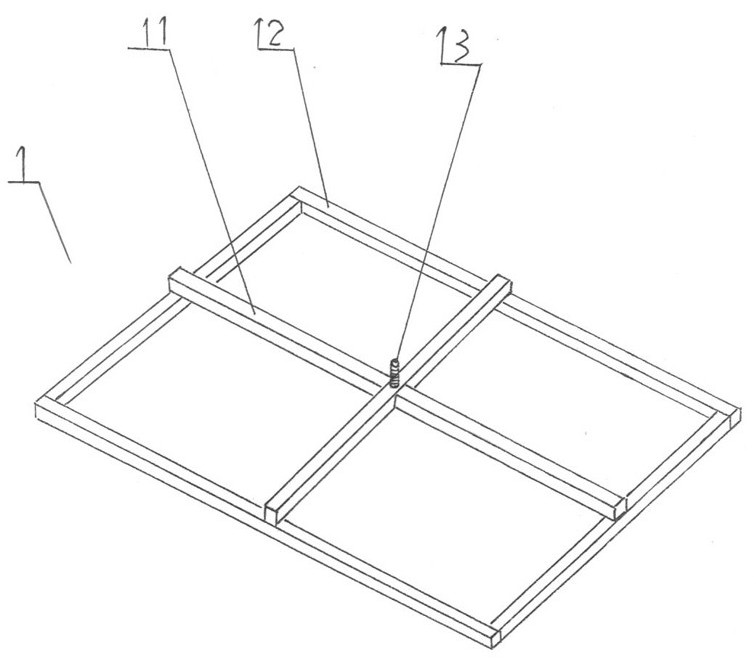

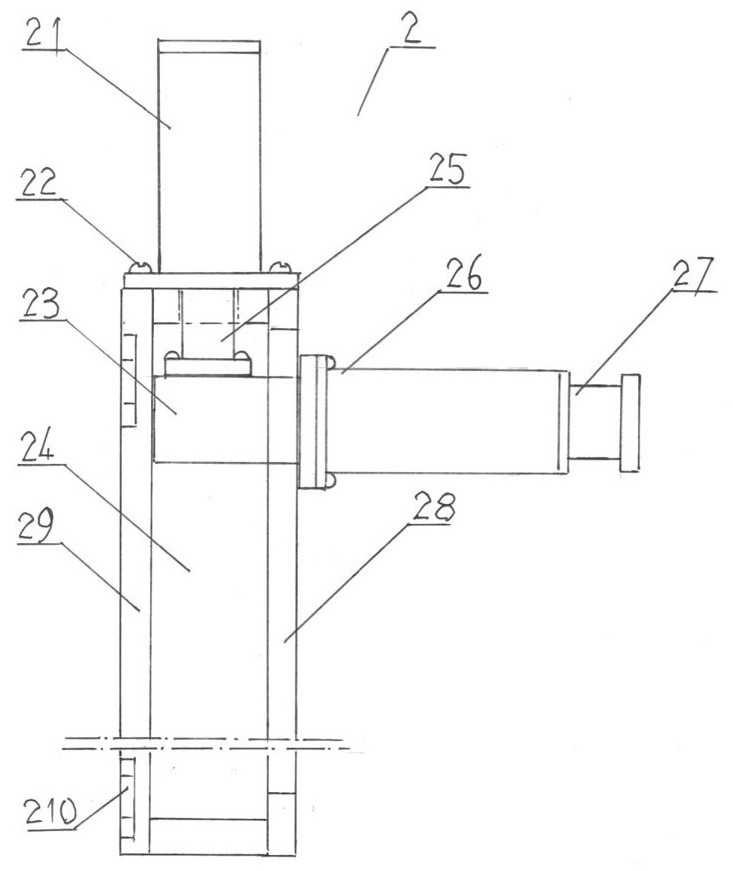

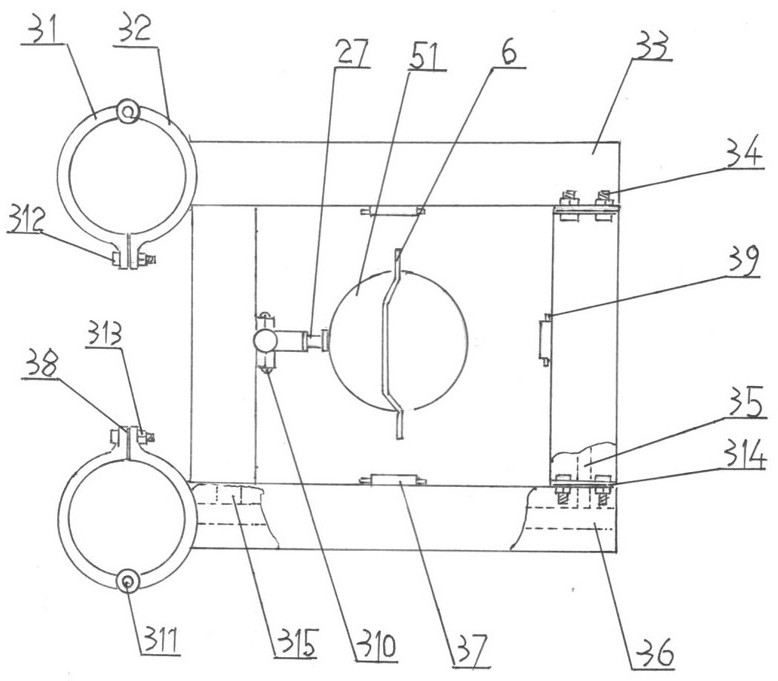

[0043] Such as Figure 1 to Figure 4 As shown, a device for installing steel sheet piles in large-diameter boulders and sandstone formations includes a casing construction measurement and positioning device 1, a steel sheet pile movable sample positive device 2, and a mobile operating platform 3.

[0044] Such as figure 1 As shown, the tube construction measurement and positioning device can accurately position the measuring prism at the center of the upper end of the steel tube, track the measurement of the steel tube in real time, and ensure the accuracy and verticality of the position of the steel tube.

[0045] The measuring and positioning device for tube construction is as follows: a cross-shaped bracket 11 is arranged on the upper end of a square frame 12, and the outer ends of the lower end surface of the cross-shaped bracket are respectively fixed with the middle parts of the four sides of the corresponding square frame. The center point of the frame is provided wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com