An environment-friendly comprehensive accelerator pre-dispersed masterbatch and its preparation method and application

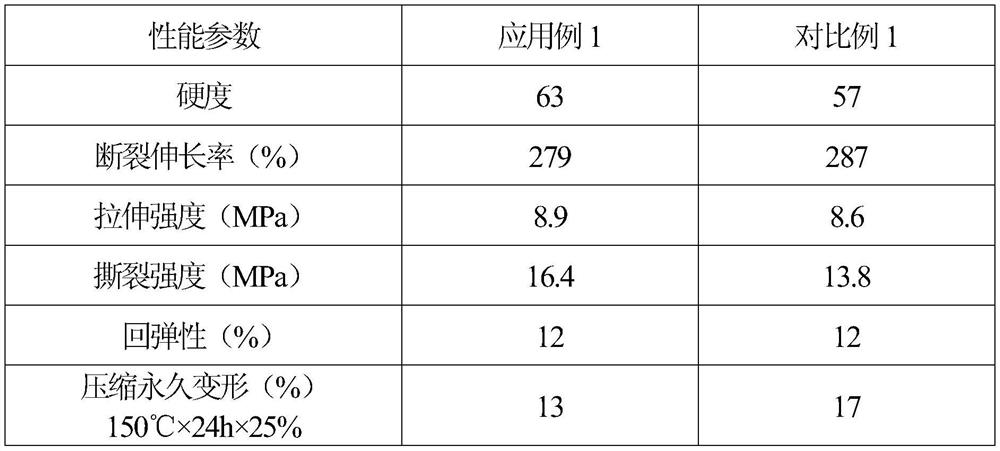

A pre-dispersed masterbatch and accelerator technology, applied in the field of rubber additives, can solve problems such as prone to surface blooming and affect the quality and performance of rubber products, so as to improve compression set and anti-aging performance, and eliminate blooming Phenomenon, eliminate the effect of easy blooming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

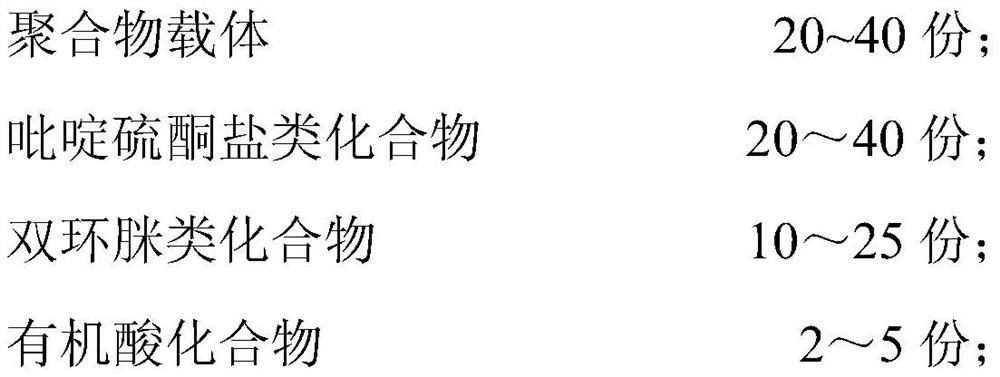

Method used

Image

Examples

Embodiment 1

[0049] Environmentally friendly comprehensive accelerator pre-dispersed masterbatches include 35 parts of acrylate rubber, 17 parts of zinc pyrithione, 21 parts of DBU, 5 parts of isooctanoic acid, 13 parts of white carbon black, 5.9 parts of dioctyl phthalate, oleic acid 3 parts of amide, 0.1 part of yellow coloring agent.

[0050] (1) Add acrylate rubber and dioctyl phthalate to a pressure-type internal mixer, and mix for 7 minutes at a mixing temperature of 60°C and a rotor speed of 50r / min;

[0051] (2) Add white carbon black and oleic acid amide to the internal mixer, and continue mixing for 7 minutes at a mixing temperature of 60°C and a rotor speed of 50r / min;

[0052] (3) Continue to add zinc pyrithione, DBU, isooctanoic acid, and yellow colorant to the internal mixer, and continue mixing for 8 minutes under the conditions of mixing temperature of 70°C and rotor speed of 65r / min to obtain pre-dispersed Gum;

[0053] (4) Add the pre-dispersed rubber compound in step (...

Embodiment 2

[0070] The environment-friendly comprehensive accelerator pre-dispersed masterbatch includes 24 parts of ethylene-acrylate rubber, 23 parts of molybdenum pyrithione, 23 parts of TBD, 5 parts of stearic acid, 13 parts of calcium carbonate, 9 parts of acetyl tributyl citrate, 3 parts of erucamide. (1) Add ethylene-acrylate rubber and acetyl tributyl citrate to a pressure-type internal mixer, and mix for 8 minutes at a mixing temperature of 100°C and a rotor speed of 100r / min;

[0071] (2) Add calcium carbonate and erucamide to the internal mixer, and continue mixing for 10 minutes at a mixing temperature of 70°C and a rotor speed of 60r / min;

[0072] (3) Continue to add molybdenum pyrithione, 1,5,7-triazabicyclo[4.4.0]dec-5-ene and stearic acid to the internal mixer, and the mixing temperature is 85℃, the rotor Continue mixing for 10 minutes under the condition that the rotating speed is 50r / min, and prepare the pre-dispersed rubber compound;

[0073] (4) Add the pre-dispersed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com