High-performance bonding modification activator for building solid waste treatment

A high-performance, activator technology, applied in the direction of solid waste management, sustainable waste treatment, climate sustainability, etc., can solve the problems of difficult control of setting time, less attention to bonding performance, poor bonding performance, etc., to achieve Good biodegradability, low gas permeability, high toughness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

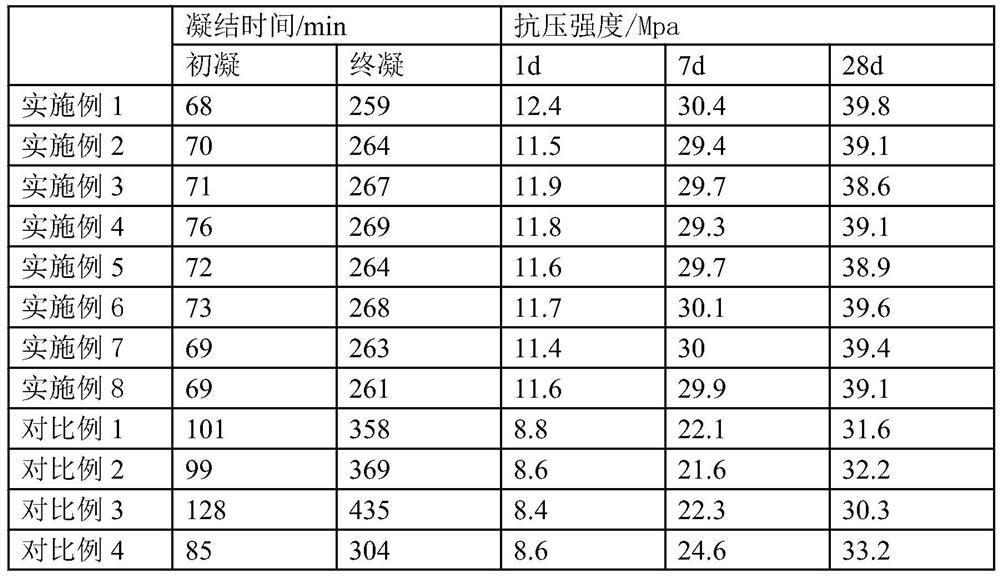

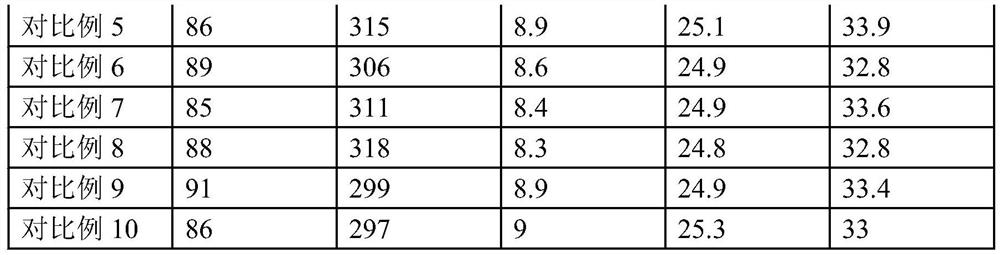

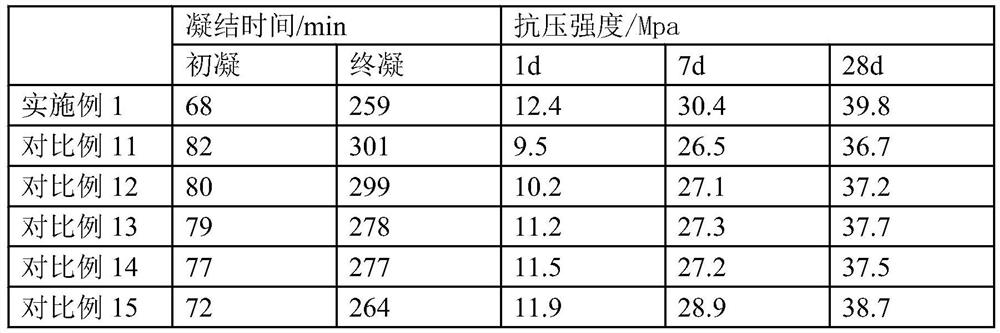

Examples

Embodiment 1

[0034] Embodiment 1: a kind of high-performance bonding modification activator for building solid waste treatment is characterized in that: comprise three parts, and A part comprises water glass, sodium carbonate, hydrotalcite, fluorogypsum and sodium hydroxide; Water glass , the mass ratio of sodium carbonate, hydrotalcite, fluorogypsum and sodium hydroxide is 12:3:3:15:1; part B includes titanyl sulfate, acid and halogen salt, titanium sulfate, acid and halogen salt The mass ratio is 8:3:2; Part C is polypropylene carbonate, redispersible latex powder and nano-silica ethanol solution, polypropylene carbonate, re-dispersible latex powder and nano-silica ethanol solution The mass ratio is 4:4:1. Described acid is hydrochloric acid; Described redispersible latex powder is acrylic acid copolymer; The modulus of water glass is 1.2; The mass ratio of A, B, C part is 15:2:5; The particle diameter of silicon oxide is 60 nm. The halogen salt is sodium chloride. The fluorogypsum is...

Embodiment 2

[0035] Embodiment 2: a kind of high-performance adhesive modification activator for building solid waste treatment is characterized in that: comprise three parts, and A part comprises water glass, sodium carbonate, hydrotalcite, fluorogypsum and sodium hydroxide; Water glass , the mass ratio of sodium carbonate, hydrotalcite, fluorogypsum and sodium hydroxide is 5:3:3:15:1; part B includes titanyl sulfate, acid and halogen salt, titanium sulfate, acid and halogen salt The mass ratio is 8:3:2; Part C is polypropylene carbonate, redispersible latex powder and nano-silica ethanol solution, polypropylene carbonate, re-dispersible latex powder and nano-silica ethanol solution The mass ratio is 4:4:1. Described acid is hydrochloric acid; Described redispersible latex powder is acrylic acid copolymer; The modulus of water glass is 1.2; The mass ratio of A, B, C part is 15:2:5; The particle diameter of silicon oxide is 60 nm. The halogen salt is sodium chloride. The fluorogypsum is...

Embodiment 3

[0036] Embodiment 3: a kind of high-performance bonding modification activator for building solid waste treatment is characterized in that: comprise three parts, and A part comprises water glass, sodium carbonate, hydrotalcite, fluorogypsum and sodium hydroxide; Water glass , the mass ratio of sodium carbonate, hydrotalcite, fluorogypsum and sodium hydroxide is 12:3:3:10:1; part B includes titanyl sulfate, acid and halogen salt, titanyl sulfate, acid and halogen salt The mass ratio is 8:3:2; Part C is polypropylene carbonate, redispersible latex powder and nano-silica ethanol solution, polypropylene carbonate, re-dispersible latex powder and nano-silica ethanol solution The mass ratio is 4:4:1. Described acid is hydrochloric acid; Described redispersible latex powder is acrylic acid copolymer; The modulus of water glass is 1.2; The mass ratio of A, B, C part is 15:2:5; The particle diameter of silicon oxide is 60 nm. The halogen salt is sodium chloride. The fluorogypsum is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com