Preparation method of metal substrate heat insulating protective coating structure and metal substrate heat insulating protective coating structure

A technology for metal substrates and protective coatings, applied in coatings, devices for coating liquids on surfaces, epoxy resin coatings, etc., can solve problems such as limited chemical bond strength, damage to heat insulation and protective coatings, and corrosion of equipment and pipelines , to achieve excellent waterproof effect, good anti-corrosion effect and anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

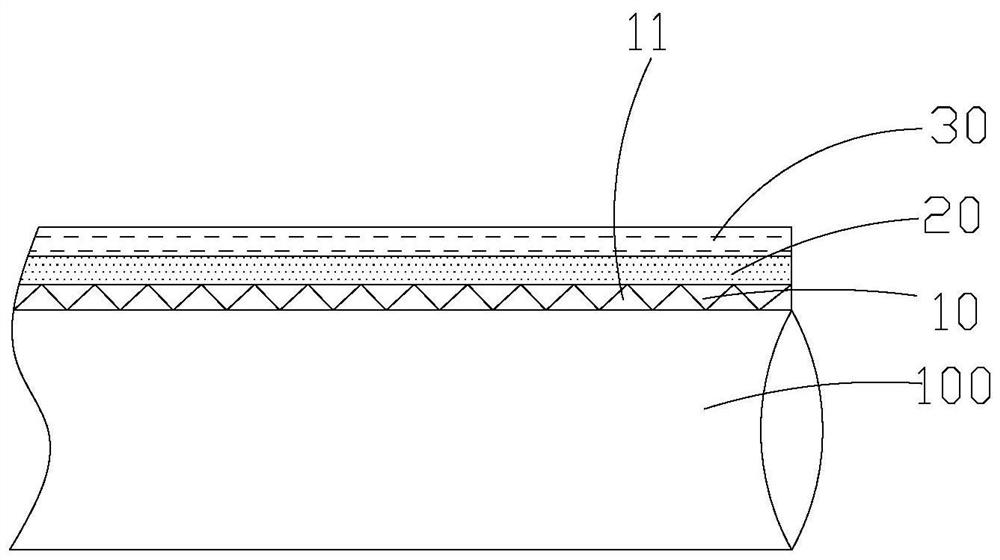

[0047] A method for preparing a metal substrate thermal insulation protective coating structure, comprising the following steps:

[0048] 1) Surface treatment of the metal substrate: removing impurities attached to the surface of the metal substrate 100;

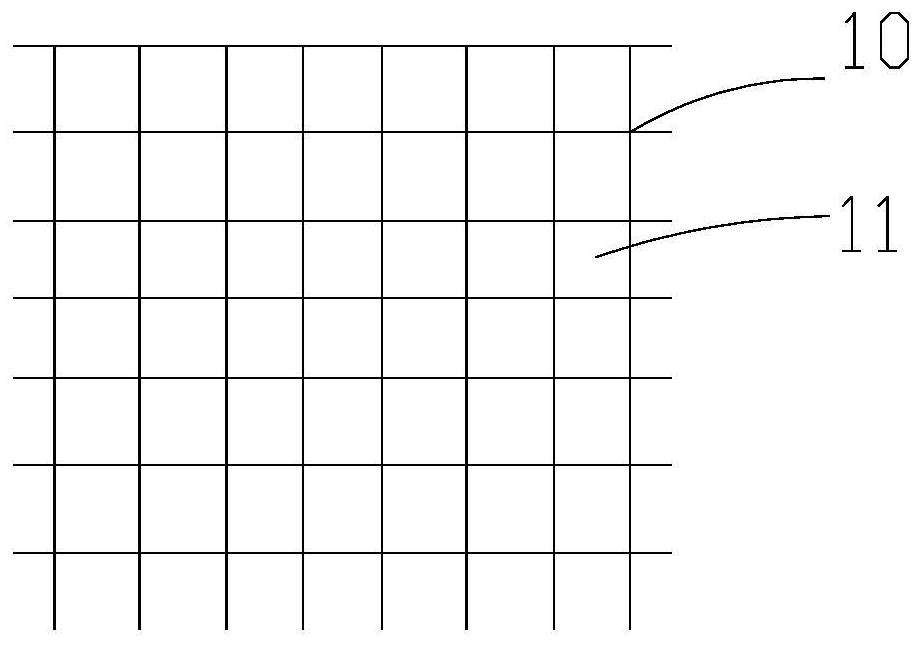

[0049]2) Setting metal mesh: covering a layer of metal mesh 10 on the surface of the metal substrate 100, and a plurality of meshes 11 are arranged on the metal mesh 10;

[0050] 3) Setting the insulation layer: coating the insulation paint at least partially in the grid 11 of step 2) to form the insulation layer 20;

[0051] 4) Installing a protective layer: spraying a protective paint on the outside of the thermal insulation layer 20 in step 3) to form a protective layer 30 .

[0052] The thickness of the metal mesh 10 in the step 2) is 0.2-0.6 mm, the aperture size of the mesh 11 is 4-10 mm, and the metal material used in the metal mesh 10 is more active than the metal material used in the metal substrate. The activity ...

Embodiment 1

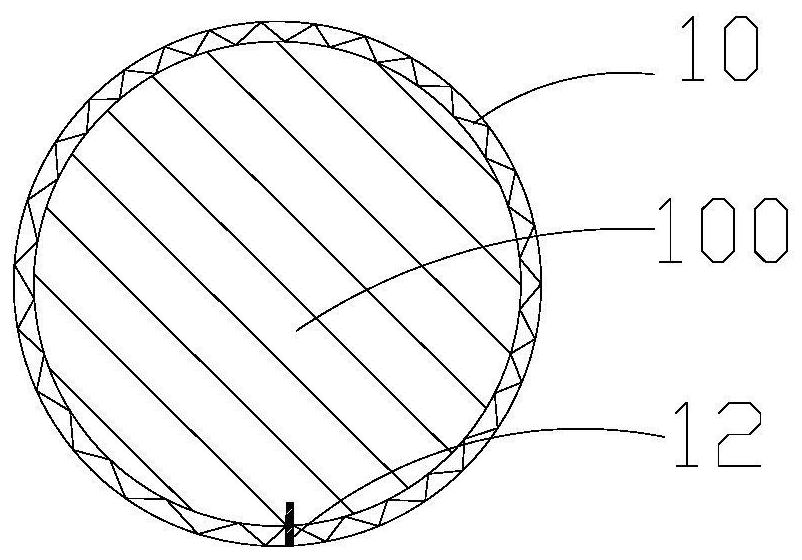

[0063] The thermal insulation and protective coating structure of the metal substrate in this embodiment is used for thermal insulation and protection of the metal substrate 100. The metal substrate 100 is a carbon steel pipe. The thermal insulation and protective coating structure of the metal substrate includes in turn from the inside to the outside: metal The mesh 10 , the insulation layer 20 and the protective layer 30 , the metal mesh 10 is covered on the outside of the metal substrate 100 , and the metal mesh 10 is attached to the metal substrate 100 and arranged.

[0064] The metal mesh 10 is provided with a plurality of grids 11, the grids 11 are diamond-shaped holes with diagonals of 8mm and 4mm respectively, the metal mesh 10 is an aluminum grid, and the insulation layer 10 is partially located in the grid 11. The thickness of the metal mesh 10 is 0.6mm; the insulation layer 20 is formed by thermal insulation coating, and the thermal insulation coating is mainly compo...

Embodiment 2

[0075] The thermal insulation and protective coating structure of the metal substrate in this embodiment is used for thermal insulation and protection of the metal substrate 100. The metal substrate 100 is a carbon steel pipe. The thermal insulation and protective coating structure of the metal substrate includes in turn from the inside to the outside: metal The mesh 10 , the insulation layer 20 and the protective layer 30 , the metal mesh 10 is covered on the outside of the metal substrate 100 , and the metal mesh 10 is attached to the metal substrate 100 and arranged.

[0076] The metal mesh 10 is provided with a plurality of grids 11, the grids 11 are diamond-shaped holes with diagonals of 8mm and 4mm respectively, the metal mesh 10 is an aluminum grid, and the insulation layer 10 is partially located in the grid 11. The thickness of the metal mesh 10 is 0.4mm; the insulation layer 20 is formed by thermal insulation coating, and the thermal insulation coating is mainly compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com