Flux and solder paste

A flux and solvent technology, applied in the direction of welding media, welding equipment, welding/cutting media/materials, etc., can solve problems such as ball loss, solder ball misalignment, solder solder can't be infiltrated and spread equally, and achieve low residue , The effect of suppressing the amount of residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

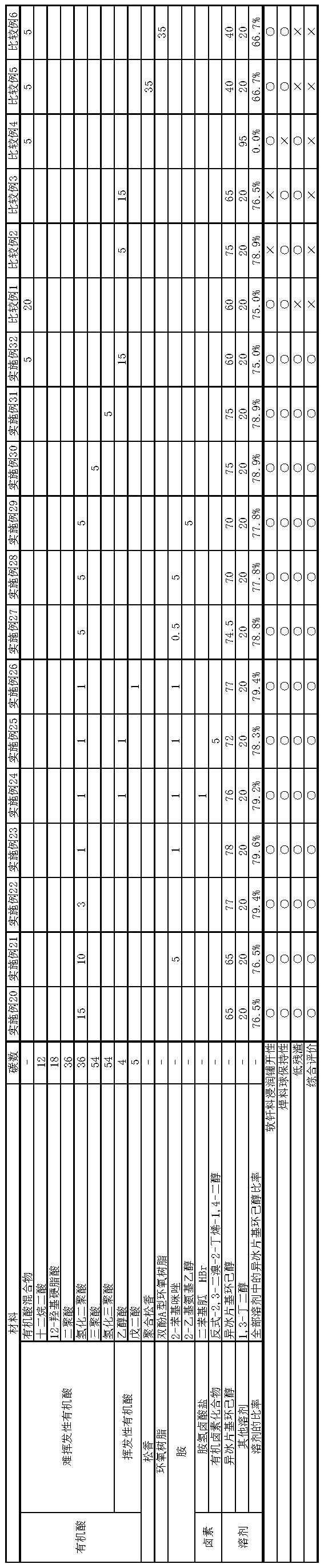

[0066] The fluxes of Examples and Comparative Examples were prepared with the compositions shown in Tables 1 and 2 below, and the wetting and spreading properties of solder, retention of solder balls, and amount of residue were verified. In addition, the composition rate in Table 1 and Table 2 excludes the ratio of isobornylcyclohexanol, and the whole amount of flux was set as 100 wt (weight)%.

[0067]

[0068] (1) Verification method

[0069] Print the fluxes of each embodiment and each comparative example on a Cu plate with a diameter of φ0.34mm and a thickness of t=0.2mm, and then mount Ag as 3wt%, Cu as 0.5wt%, and the remainder as a solder of Sn ( Sn-3Ag-0.5Cu) formed solder balls. The diameter of the solder ball is φ0.3 mm. The number of evaluation objects was 50 in each Example and each Comparative Example. Using a reflow oven, the N 2 Under the atmosphere, the test object prepared as above was heated from 25° C. to 250° C. at a heating rate of 5° C. / second, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com