Method for preventing slagging based on design angle of boiler

A boiler design and anti-slagging technology, applied in the field of safe operation of thermal power plants, can solve problems such as aggravation, impact, and boiler slagging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with the examples, the specific implementation of the present invention will be further described in detail. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0017] This embodiment provides an anti-slagging method based on the boiler design perspective, including:

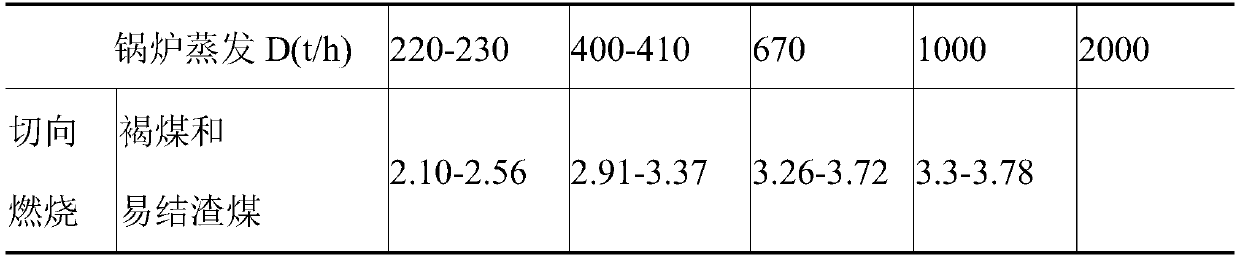

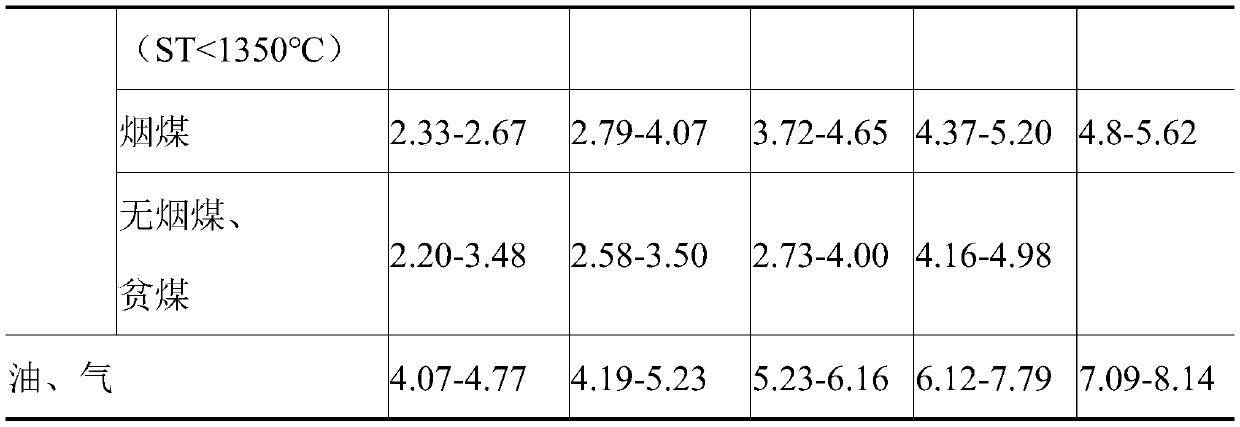

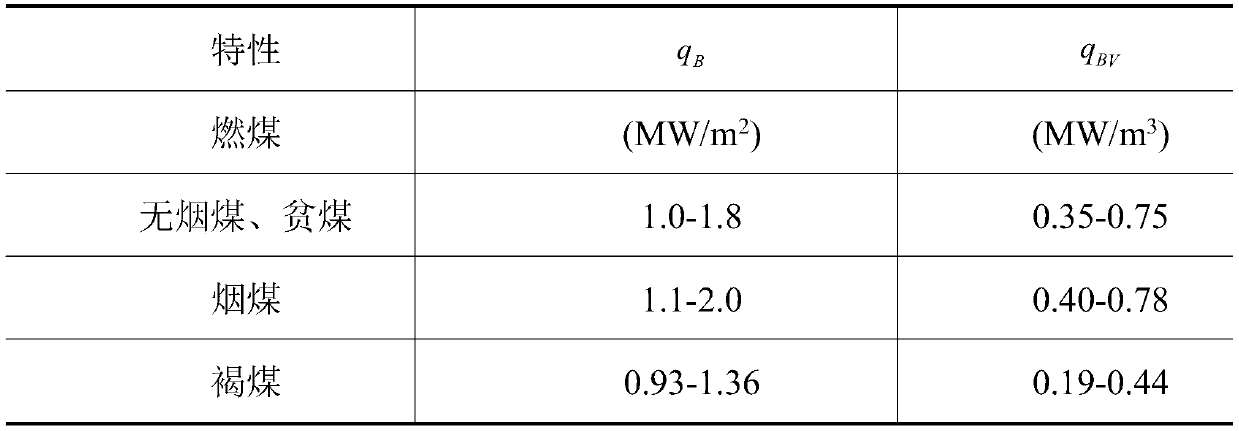

[0018] Select the thermal parameters of the furnace that can reduce the temperature level of the burner area, make the heat load in the furnace uniform and ensure that the pulverized coal has enough residence time to burn out in the upper part of the furnace. The type of burner and the arrangement of nozzles reduce the imaginary tangential diameter of the burner, the thermal power of the single primary air nozzle of the burner and the ratio of primary and secondary air momentum, so that the furnace has a good aerodynamic working condition and prevents the air flow with powder from being deviated. Dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com