A production method of high-strength corrosion-resistant austenitic stainless steel plate and strip

A technology of austenitic stainless steel and production method, which is applied in the field of production of austenitic stainless steel plate and strip, and can solve the problem of increasing the sensitivity of grain boundary cracking and grain boundary failure behavior, increasing the proportion of low-energy grain boundaries, and low yield strength, etc. problems, to achieve the effect of grain boundary characteristic distribution, grain size refinement, and large cumulative deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The invention discloses a production method of a high-strength corrosion-resistant austenitic stainless steel plate and strip. The austenitic stainless steel described in this embodiment is an annealed 304 austenitic stainless steel strip with a thickness of 1 mm.

[0034] The production method of the present embodiment is:

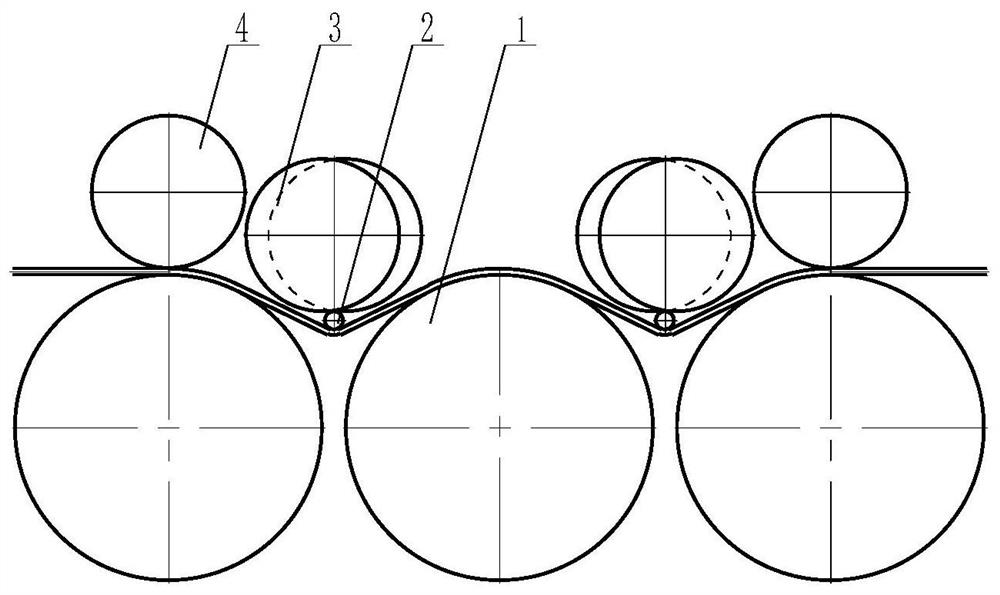

[0035] Step 1. Using an "asymmetric cyclic bending deformation device for metal sheets and strips", the hot-rolled or annealed austenitic stainless steel strips are subjected to asymmetric cyclic bending deformation, and the deformed austenitic stainless steel Strips are annealed.

[0036] Step 2, using an "asymmetric cyclic bending deformation device for metal plate and strip", the austenitic stainless steel strip after the annealing treatment in step 1 is subjected to asymmetric cyclic bending deformation, and the re-deformed austenitic stainless steel strip is subjected to asymmetrical cyclic bending deformation. The body stainless steel strip...

Embodiment 2

[0053] The invention discloses a production method of a high-strength corrosion-resistant austenitic stainless steel plate and strip. The austenitic stainless steel described in this embodiment is a hot-rolled 316LN austenitic stainless steel strip with a thickness of 25mm.

[0054] The production method of the present embodiment is:

[0055] Step 1. Using an "asymmetric cyclic bending deformation device for metal sheets and strips", the hot-rolled or annealed austenitic stainless steel strips are subjected to asymmetric cyclic bending deformation, and the deformed austenitic stainless steel Strips are annealed.

[0056] Step 2, using an "asymmetric cyclic bending deformation device for metal plate and strip", the austenitic stainless steel strip after the annealing treatment in step 1 is subjected to asymmetric cyclic bending deformation, and the deformed austenitic stainless steel The strip is then annealed.

[0057] Step 3. Step 2 is repeated twice to refine the grain si...

Embodiment 3

[0073] The invention discloses a production method of a high-strength corrosion-resistant austenitic stainless steel plate and strip. The austenitic stainless steel described in this embodiment is a hot-rolled 310S austenitic stainless steel strip with a thickness of 10 mm.

[0074] The production method of the present embodiment is:

[0075] Step 1. Using an "asymmetric cyclic bending deformation device for metal sheets and strips", the hot-rolled or annealed austenitic stainless steel strips are subjected to asymmetric cyclic bending deformation, and the deformed austenitic stainless steel Strips are annealed.

[0076] Step 2, using an "asymmetric cyclic bending deformation device for metal plate and strip", the austenitic stainless steel strip after the annealing treatment in step 1 is subjected to asymmetric cyclic bending deformation, and the deformed austenitic stainless steel The strip is then annealed.

[0077] Step 3. Step 2 is repeated once to refine the grain siz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com