Process for brewing baijiu by low-temperature bacteria cultivation through simple yeast bed

A low-temperature, simple technology, applied in the preparation of alcoholic beverages, methods based on microorganisms, microorganisms, etc., can solve the problems of large temperature differences, growth of harmful bacteria, uneven enzyme content, etc., to achieve excellent product quality and sweet wine , long lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

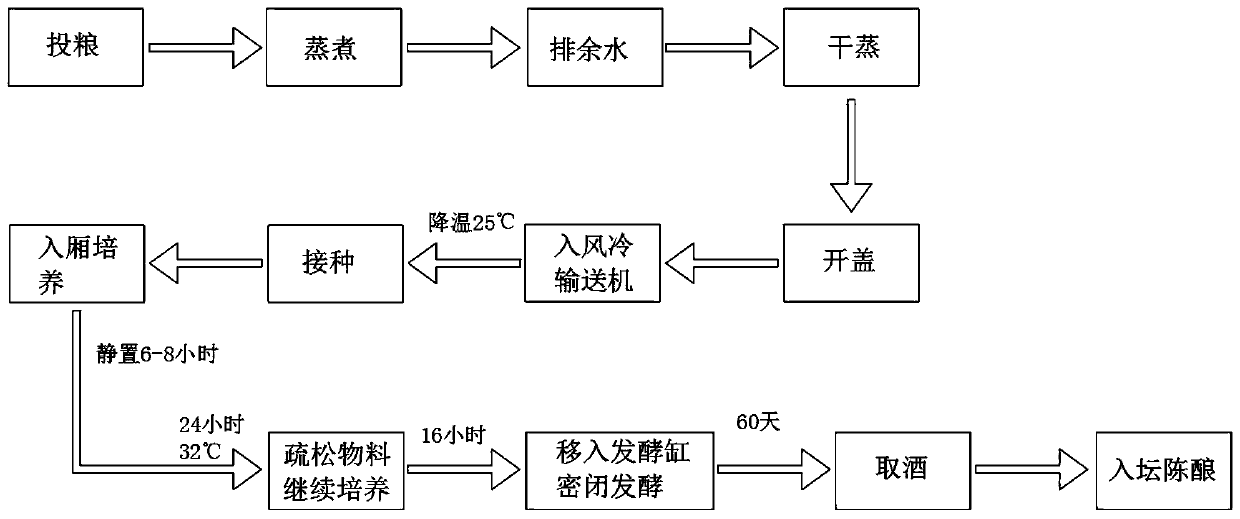

[0028] See figure 1 In the embodiment of the present invention, a process for brewing liquor by low-temperature culture of simple koji bed, the specific steps are as follows:

[0029] (1) Raw material cooking:

[0030] a. Put the raw materials into the atmospheric steaming material for cooking, the raw materials are specifically sorghum and wheat, boil for 30 minutes, and then drain the remaining water;

[0031] b. After the residual water is drained, the raw materials are dry-steamed for 30 minutes, and the raw materials after dry-steaming are in the state of boiling and blooming;

[0032] (2) Cooling and inoculation: Open the lid of the steaming pipe in step (1), take out the raw materials, and then put the raw materials into the air-cooled conveyor. The conveyor belt of the air-cooled machine cools the raw materials through air cooling and transports them to the twisting machine. The dragon inoculation machine is evenly inoculated with Aspergillus oryzae Rhizopus yeast, and the ra...

Embodiment 2

[0037] See figure 1 In the embodiment of the present invention, a process for brewing liquor by low-temperature culture of simple koji bed, the specific steps are as follows:

[0038] (1) Raw material cooking:

[0039] a. Put the raw materials into the normal pressure steaming material, the raw materials are specifically sorghum and wheat, boil for 33 minutes, and then drain the remaining water;

[0040] b. After the residual water is drained, the raw materials are dry-steamed for 33 minutes, and the raw materials after dry-steaming are in the state of boiling and blooming;

[0041] (2) Cooling and inoculation: Open the lid of the steaming pipe in step (1), take out the raw materials, and then put the raw materials into the air-cooled conveyor. The conveyor belt of the air-cooled machine cools the raw materials through air cooling and transports them to the twisting machine. The dragon inoculation machine is evenly inoculated with Aspergillus oryzae Rhizopus yeast, and the raw materi...

Embodiment 3

[0046] See figure 1 In the embodiment of the present invention, a process for brewing liquor by low-temperature culture of simple koji bed, the specific steps are as follows:

[0047] (1) Raw material cooking:

[0048] a. Put the raw materials into the normal pressure steaming material, the raw materials are specifically sorghum and wheat, boil for 35 minutes, and then drain the remaining water;

[0049] b. After the residual water is drained, the raw materials are dry-steamed for 35 minutes, and the raw materials after dry-steaming are in a state of boiling and blooming;

[0050] (2) Cooling and inoculation: Open the lid of the steaming pipe in step (1), take out the raw materials, and then put the raw materials into the air-cooled conveyor. The conveyor belt of the air-cooled machine cools the raw materials through air cooling and transports them to the twisting machine. The dragon inoculation machine is evenly inoculated with Aspergillus oryzae Rhizopus yeast, and the raw material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com