A kind of fluorocarbon modified waterborne alkyd resin coating and its preparation method and application

A water-based alkyd resin and fluorocarbon modification technology, which is applied in polyester coatings, coatings, etc., can solve the problems of high price and no significant improvement in the resistance of water-based alkyd coatings, and achieve excellent salt spray resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

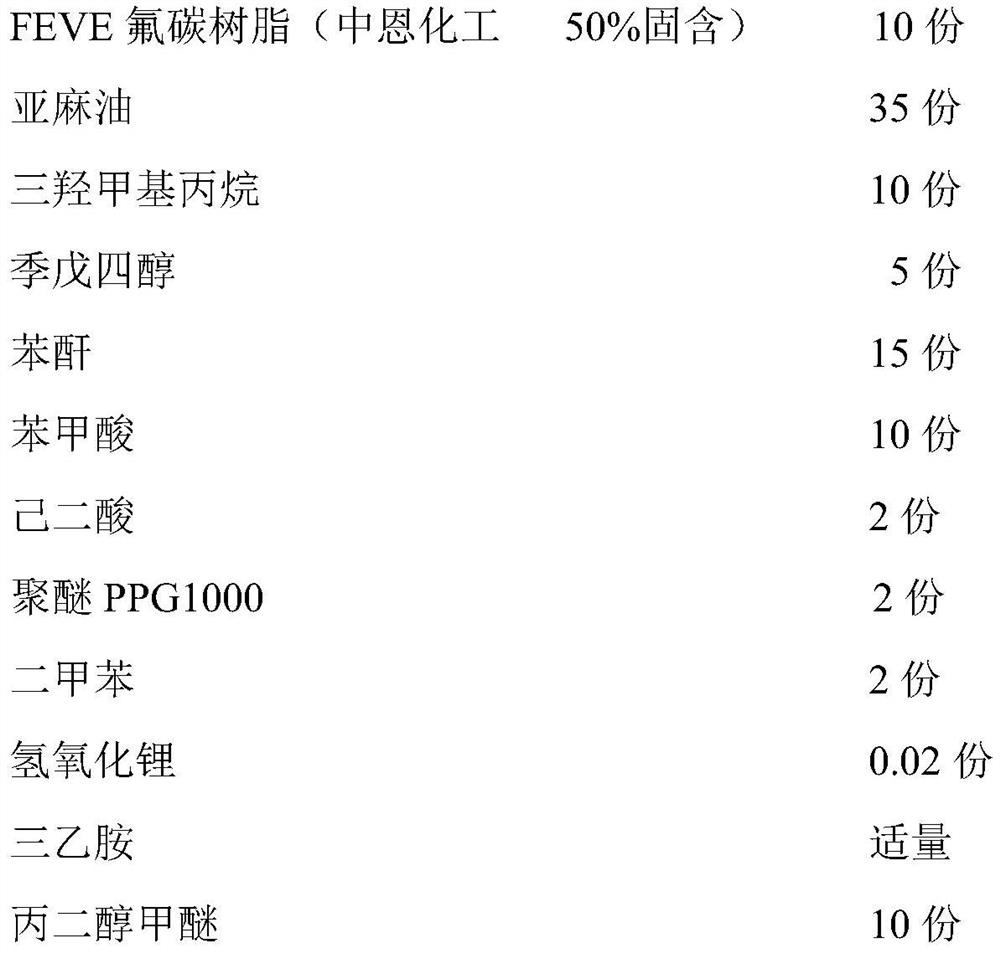

[0026] The fluorocarbon modified waterborne alkyd resin coating of the present embodiment comprises by weight:

[0027]

[0028] The specific preparation steps of the fluorocarbon modified waterborne alkyd resin coating of the present embodiment include:

[0029] 1) At room temperature, first add 15 parts of phthalic anhydride and 10 parts of FEVE resin (solution) into a three-necked flask with a condenser tube-water separator, and stir for 2 hours at 70°C.

[0030] 2) Then add 35 parts of linseed oil, 10 parts of trimethylolpropane, 5 parts of pentaerythritol, 2 parts of adipic acid, 10 parts of benzoic acid, 2 parts of polyether PPG1000 and 2 parts of xylene. Raise the temperature to 135°C and keep it warm for 20 minutes. At this time, organic streams flow out of the water separator. Continue to heat up to 180°C and keep warm for 1h.

[0031] 3) Add 0.02 parts of lithium hydroxide, then raise the temperature to 230°C, vacuumize, keep warm for 3 hours, check the acid val...

Embodiment 2

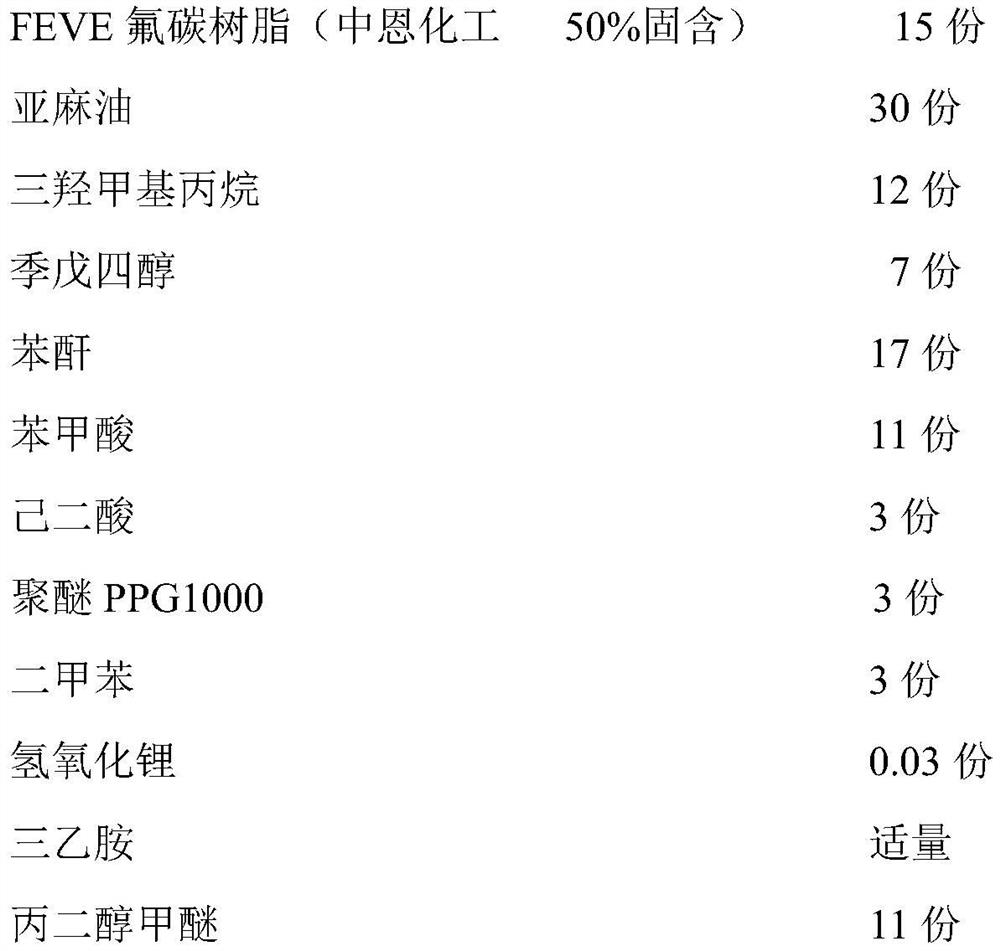

[0041] The fluorocarbon modified waterborne alkyd resin coating of the present embodiment comprises by weight:

[0042]

[0043] The specific preparation steps of the fluorocarbon modified waterborne alkyd resin coating of the present embodiment include:

[0044] 1) At room temperature, first add 17 parts of phthalic anhydride and 15 parts of FEVE resin (solution) into a three-neck flask with a condenser tube-water separator, and stir for 2 hours at 75°C.

[0045] 2) Then add 30 parts of linseed oil, 12 parts of trimethylolpropane, 7 parts of pentaerythritol, 3 parts of adipic acid, 11 parts of benzoic acid, 3 parts of polyether PPG1000 and 3 parts of xylene. Raise the temperature to 140°C and keep it warm for 30 minutes. At this time, organic streams flow out of the water separator. Continue to heat up to 185°C and keep warm for 1h.

[0046] 3) Add 0.03 parts of lithium hydroxide, then raise the temperature to 235°C, vacuumize, keep the temperature for 3 hours, and when ...

Embodiment 3

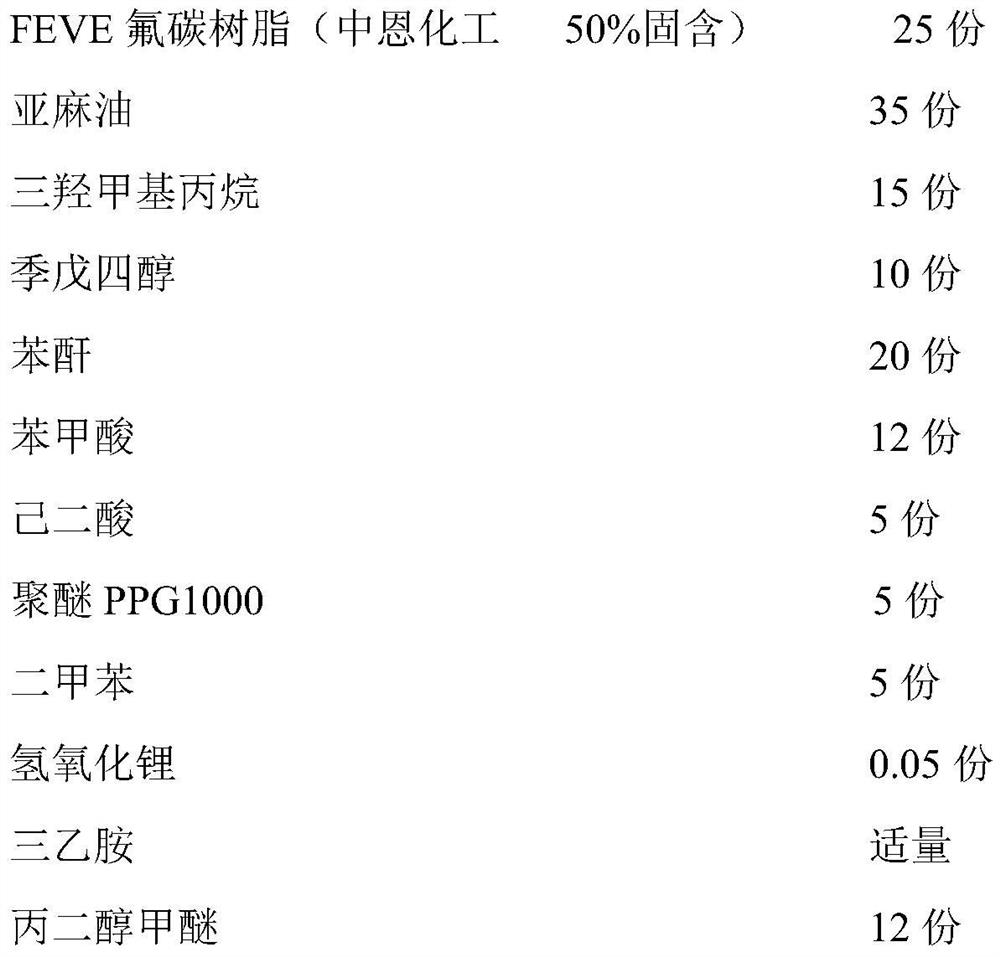

[0056] The fluorocarbon modified waterborne alkyd resin coating of the present embodiment comprises by weight:

[0057]

[0058] The specific preparation steps of the fluorocarbon modified waterborne alkyd resin coating of the present embodiment include:

[0059] 1) At room temperature, first add 20 parts of phthalic anhydride and 25 parts of FEVE resin (solution) into a three-necked flask with a condenser tube-water separator, and stir for 2 hours at 80°C.

[0060] 2) Then add 35 parts of linseed oil, 15 parts of trimethylolpropane, 10 parts of pentaerythritol, 5 parts of adipic acid, 12 parts of benzoic acid, 5 parts of polyether PPG1000 and 5 parts of xylene. Raise the temperature to 150°C and keep it warm for 35 minutes. At this time, organic streams flow out of the water separator. Continue to heat up to 190°C and keep warm for 1.5h.

[0061] 3) Add 0.05 parts of lithium hydroxide, then raise the temperature to 240°C, vacuumize, keep the temperature for 3.5 hours, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com