Low-vulnerability propellant and preparation method thereof

A technology of propellant and adhesive, which is applied in the field of low-fragile propellant and its preparation, can solve the problem that it is difficult to ensure the energy performance of the propellant, reduce the fragility of the propellant, the low fragility of the propellant and the inability to balance the energy, etc. The problem is to reduce the vulnerability response degree, improve the vulnerability response degree, and improve the mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

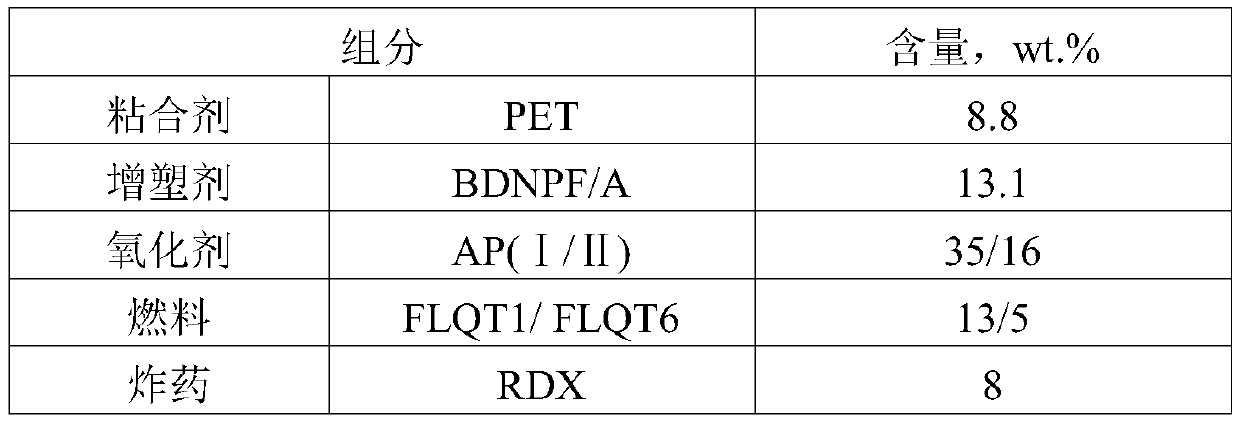

[0031] The specific formulation of the low-fragile propellant is shown in Table 1 below.

[0032] Table 1

[0033]

[0034]

[0035] The specific preparation method of the propellant is as follows:

[0036] First premix the adhesive and bonding agent at 60±2℃ for 30~60min, then add plasticizer, curing catalyst and fuel to mix evenly at room temperature; then add explosive and mix at 55±2℃ for 10~20min , then add oxidant and mix at 55±2℃ for 30~60min, finally add curing agent and mix at 55±2℃ for 20~30min.

[0037] After the uniformly mixed mixture slurry is vacuum poured into the engine at 55±2°C, the low-fragile propellant is cured and formed at a curing temperature of 60±2°C and a curing time of 6-8 days.

[0038] In the preparation process of low-fragile propellants, vertical mixers are generally used for mixing, and a vacuum casting system is used to realize the production of engine grains. The oxidant should be added in batches to avoid adding too much at one tim...

Embodiment 2

[0051] (1) The specific formula of the low-fragile propellant is shown in Table 4 below. The specific preparation method is the same as in Example 1.

[0052] Table 4

[0053]

[0054] (2) Properties of propellant:

[0055] 1) Measured specific impulse Isp of propellant: 245.8s (6.86MPa, 20℃);

[0056] 2) Propellant density ρ: 1.750g / cm 3 ;

[0057] 3) The propellant burning rate is 10.0mm / s (6.86MPa)

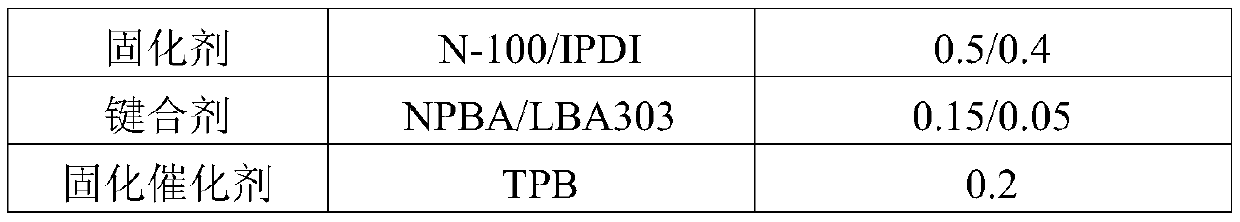

[0058] 4) The mechanical properties of the propellant are shown in Table 5.

[0059] table 5

[0060]

[0061] 5) See Table 6 for the fragility of the propellant.

[0062] Table 6

[0063] Pilot projects burn quickly slow burn bullet impact Fragment impact martyrdom jet impingement response level combustion combustion lower than burn lower than burn deflagration deflagration in conclusion pass pass pass pass pass pass

Embodiment 3

[0065] (1) The specific formulation of the low-fragile propellant is shown in Table 7 below. The specific preparation method is the same as in Example 1.

[0066] Table 7

[0067]

[0068]

[0069] (2) Properties of propellant:

[0070] 1. The measured specific impulse Isp of the propellant: 245.0s (6.86MPa, 20℃);

[0071] 2. Propellant density ρ: 1.766g / cm 3 ;

[0072] 3. The propellant burning speed is 6.0mm / s (6.86MPa)

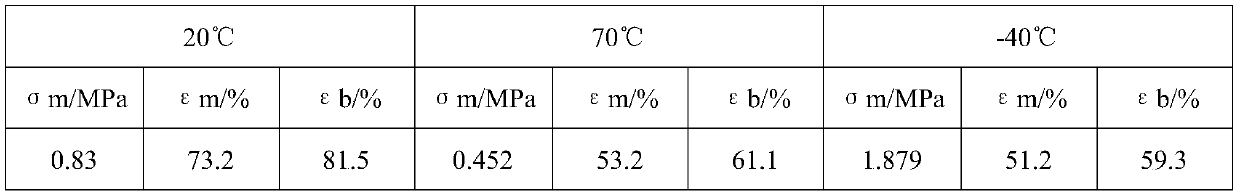

[0073] 4. The mechanical properties of the propellant are shown in Table 8.

[0074] Table 8

[0075]

[0076] 5. See Table 9 for propellant fragility.

[0077] Table 9

[0078] Pilot projects burn quickly slow burn bullet impact Fragment impact martyrdom jet impingement response level combustion combustion lower than burn combustion deflagration deflagration in conclusion pass pass pass pass pass pass

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com