Aluminothermic welding method of seamless steel rail

A seamless rail and thermite welding technology, applied in the direction of thermite welding equipment, rails, tracks, etc., can solve the problems of difficulty in construction, cracks in the transition zone of welds, and difficulty in application, so as to avoid excessive cooling and solve air holes and The effect of crack defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

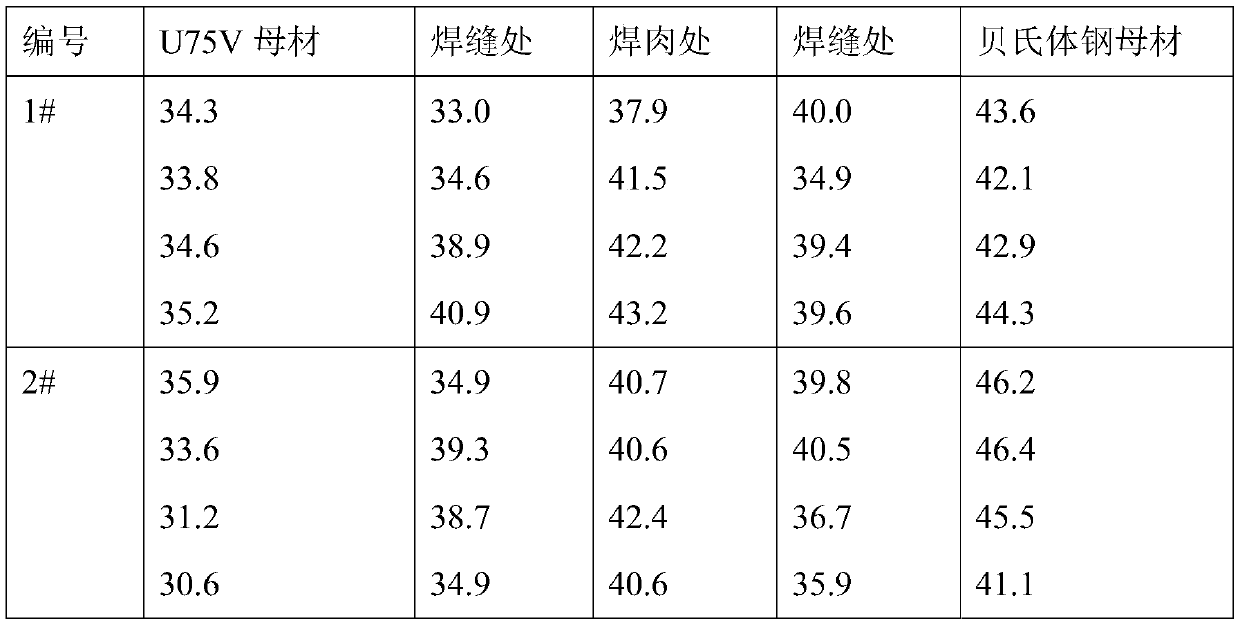

Embodiment 1

[0032] Rails, U20Mn bainite rails and U75V rails.

[0033] Thermite flux, CN105921881A thermite flux.

[0034] Time, December 2018, location, Jing County, Hebei Province, temperature minus 5°C.

[0035] The welding process is:

[0036] (1) Grinding and derusting the rail, removing the rust on the welding part of the rail end, and then heating the rail end with a propane and oxygen preheating gun at a temperature of 300-350°C, but do not heat the weld joint to avoid oxidation and carbon deposition;

[0037] (2) Align the rails so that the ends of the rails are aligned, the rail gap is 28mm, assemble, and wipe the welds again after assembly to ensure cleanliness;

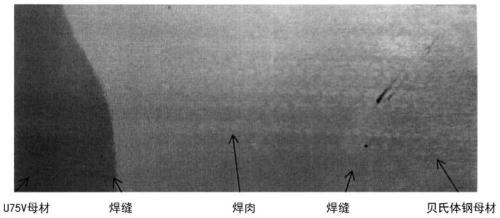

[0038] (3) Install the sand mold, use the preheating gun to heat the range of 1000mm on both sides of the rail to 37°C, and then use the preheating gun to preheat the rail for more than 5 minutes until the color of the rail head turns red; in order to reduce the distance between the rail surface to be welded and Th...

Embodiment 2

[0048] Rails, U20Mn bainite rails and U75V rails.

[0049] Thermite flux, CN105921881A thermite flux.

[0050] Time, July 2019, location, Jing County, Hebei Province.

[0051] The welding process is:

[0052] (1) Grinding and derusting the rail, removing the rust on the welding part of the rail end, and then heating the rail end with a propane and oxygen preheating gun at a temperature of 300-350°C;

[0053] (2) Align the rails so that the ends of the rails are aligned, the rail gap is 28mm, assemble, and wipe the welds again after assembly to ensure cleanliness;

[0054] (3) Install the sand mold, and then preheat the rail with a preheating gun for more than 5 minutes until the color of the rail head turns red; in order to reduce the temperature difference between the surface of the rail to be welded and the molten pool of the aluminothermic steel, which is conducive to the fusion of the joint surface Fine grains, improve the stress distribution of welded joints, improve t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com