Safe and quality-improving yak slaughtering processing method

A processing method and yak technology, which are applied in slaughtering, slaughtering accessories, slaughtering devices, etc., can solve problems such as unfavorable development of yak industry, microbial contamination of yak carcass, aging and toughness of meat, etc., so as to reduce the stress response of yak transportation and improve food safety. the effect of reducing microbial contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Step 1: Send the yaks to be slaughtered with a transportation distance of 400km to the pen to be slaughtered without eating and resting for 12 hours, and without drinking for 3 hours before slaughter. To eliminate the stress response of long-distance transportation of yaks and improve the quality of yak meat;

[0040] Step 2: Drive the yak into the flipping box, stun it, slaughter it, fasten the hind legs of the yak with an iron chain, lift it into the bloodletting track through the hoist, assassinate the bloodletting track on the bloodletting track, drain the blood for 8 minutes, and perform 30V low-voltage electrical stimulation. Time 60s, promote yak muscle contraction, accelerate muscle glycolysis, thereby speeding up the tenderization speed of yak meat, and facilitate the further discharge of blood;

[0041] Step 3: Use a shaving tool to shave off the skirt hair from top to bottom at the midline of the yak's abdomen, with a width of 25cm. Then, use high-pressure w...

Embodiment 2

[0050] 1 Materials and methods

[0051] 1.1 Test material

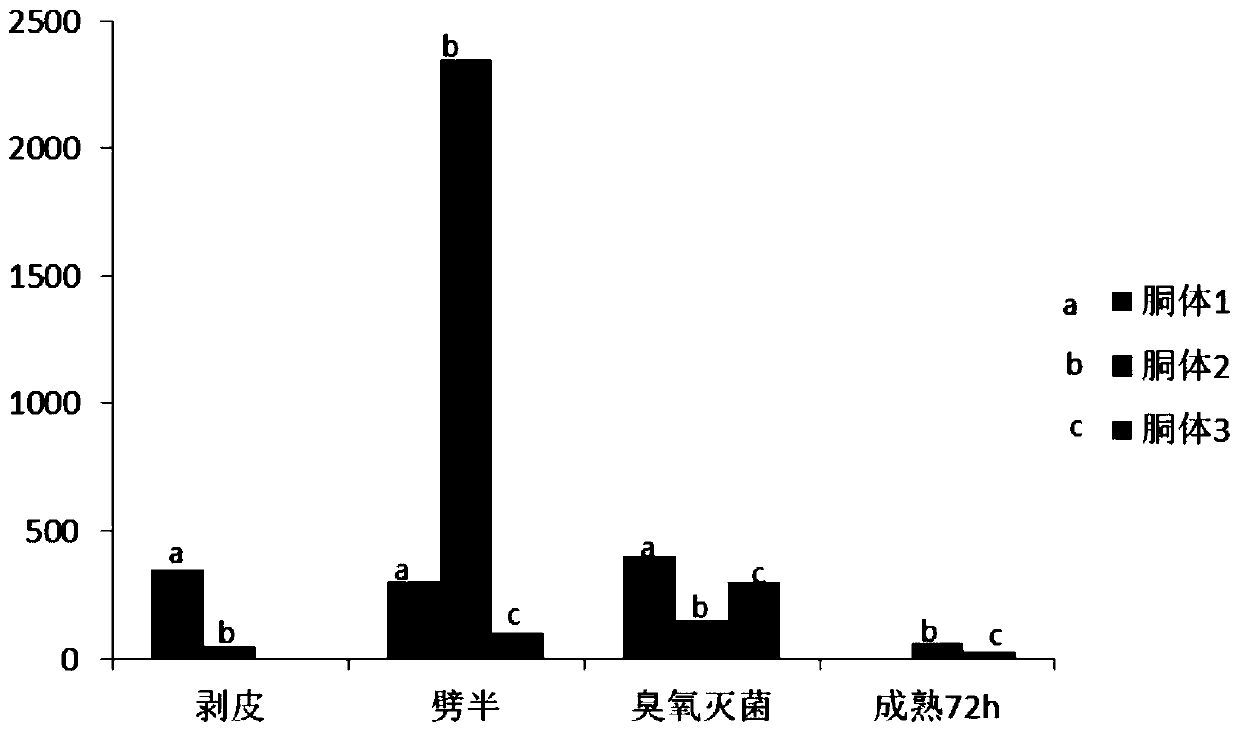

[0052] In the yak slaughtering workshop of Diqing community, three fattening yaks were selected to be stunned by electricity, and then slaughtered in accordance with the provisions of GB / T 19477 "Operational Regulations for Cattle Slaughter" and GB 18393 "Quality Inspection Regulations for Cattle and Sheep Slaughter Products". After peeling, splitting in half, and carcass ozone spraying (the relevant parameters for the use of ozone water are determined to be: ozone water concentration 6mg / L; the time for spraying the carcass is 45s.) After 5min, the three links were respectively used at the carcass outer ridge on the left side. Cut the 10×10cm square, 3cm-5cm thick muscle with a bacterial scalpel, put it into a sterile bag, store it at 0°C-2°C, and send it to the laboratory to determine the microbial content. The carcass is pushed into the cooling workshop, and after cooling and maturing for 72 hours, the yak meat is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com