Construction method of built-in diagonal steel truss deep coupling beams in superimposed shear walls with openings

A technology of superimposed shear walls and steel trusses, which is applied in the processing of walls and building materials, and earthquake resistance, etc., can solve problems such as difficulties in the arrangement of oblique steel bars, reduce assembly and construction links, have strong versatility, and reduce the difficulty of construction operations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

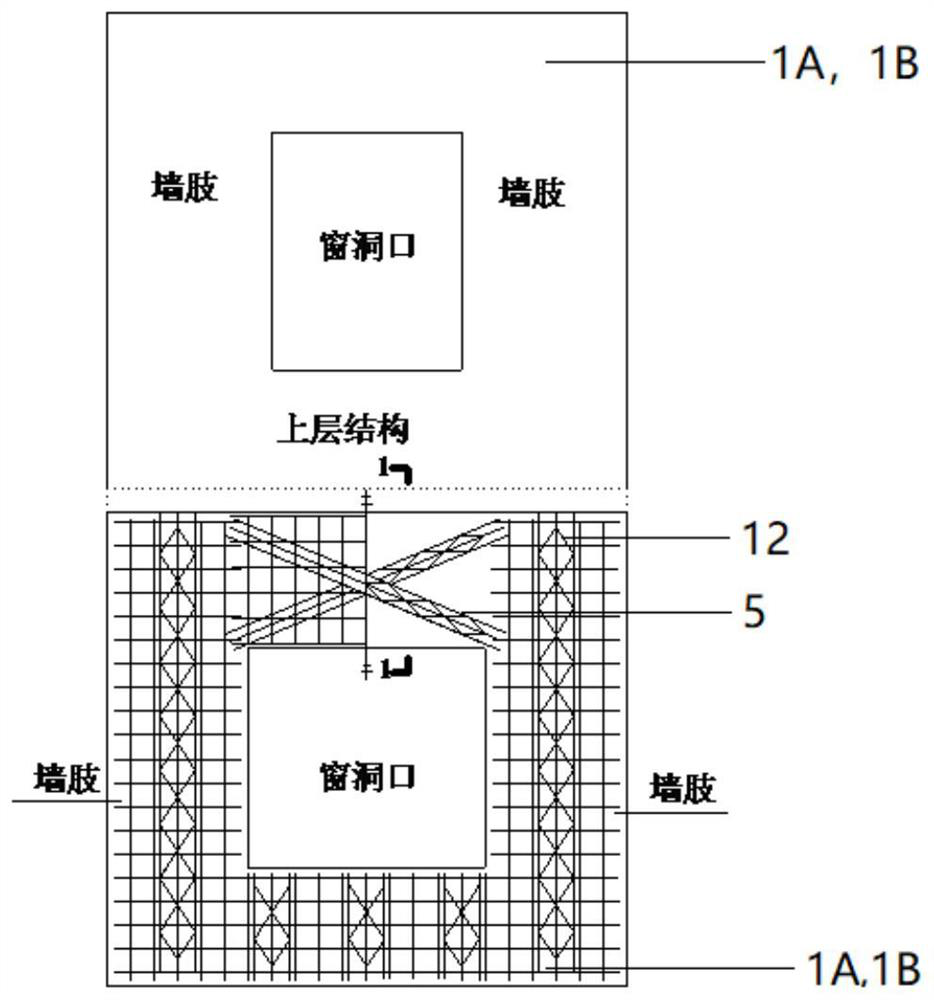

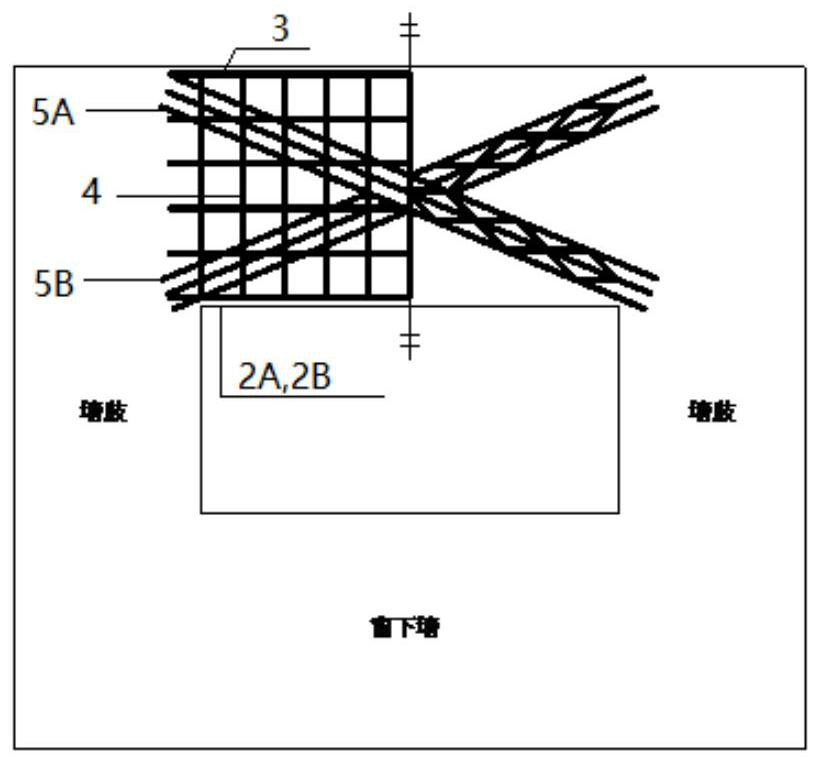

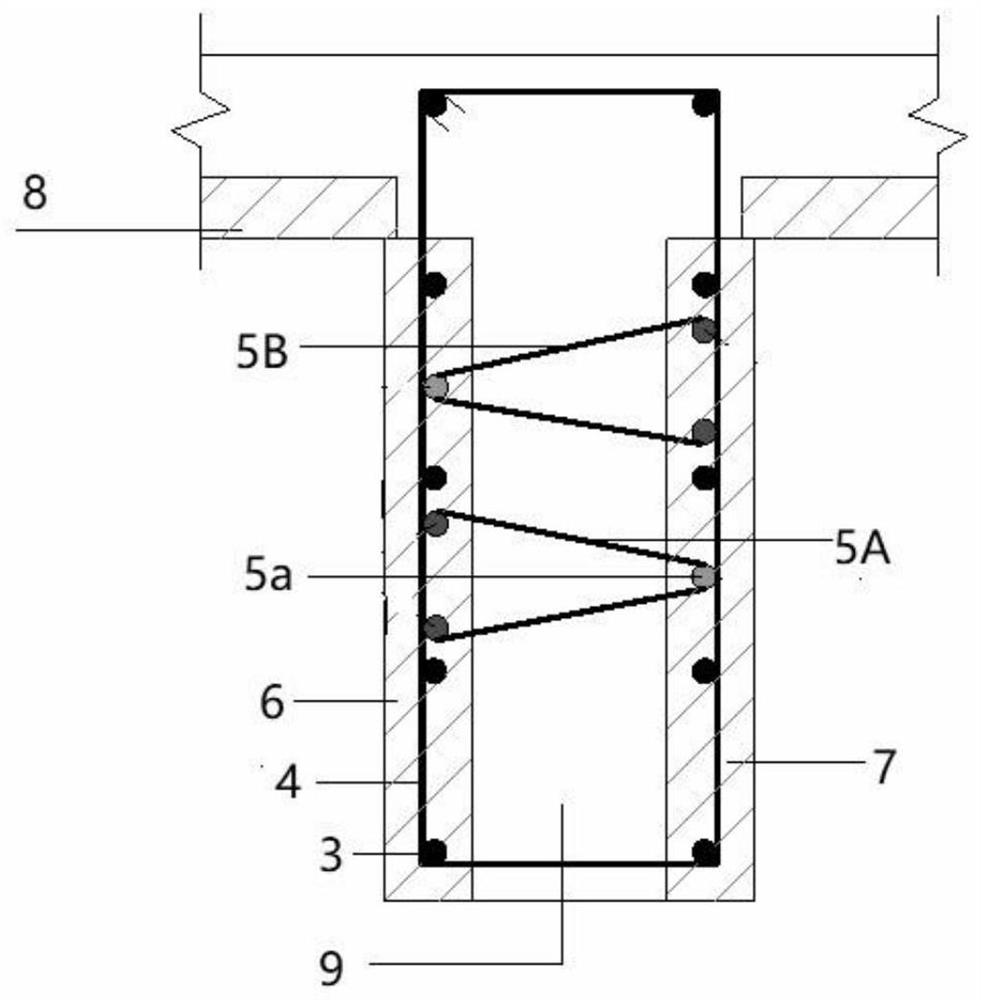

[0024] Such as figure 1 , figure 2 with image 3 The double-sided laminated shear wall panel with the opening shown includes the prefabricated double-sided laminated shear wall panel 1A, the prefabricated double-sided laminated connecting beam 2A, the longitudinal stress reinforcement bar 3 of the laminated deep connecting beam, and the The outer stirrup 4 of the longitudinal stress reinforcement 3 of the deep connecting beam, the cross-type diagonal reinforcement truss 5 arranged in the stirrup 4 and inserted between the longitudinal stress reinforcement 3 of the laminated deep coupling beam, and the post-cast concrete 9 of the core layer . The above-mentioned double-sided laminated shear wall 1A includes the inner leaf prefabricated laminated wall panel 6 and the outer leaf prefabricated laminated wall panel 7, and the inner leaf prefabricated laminated wall panel 6 and the outer leaf prefabricated laminated wall panel 7 are vertically arranged The steel bar trusses 12 a...

Embodiment 2

[0033] Such as figure 1 , figure 2 with Figure 4 The single-sided laminated shear wall panels with openings shown include prefabricated single-sided laminated shear wall panels 1B, prefabricated single-sided laminated connecting beams 2B, longitudinally stressed reinforcement bars 3 for laminated deep connecting beams, and Stirrups 4 on the outside of the longitudinal stress reinforcement 3 of the connecting beam, the cross-shaped diagonal reinforcement truss 5 arranged in the stirrup 4 and inserted between the longitudinal stress reinforcement 3 of the laminated deep coupling beam longitudinal reinforcement, and behind the core layer Pouring concrete9. The above-mentioned single-sided laminated shear wall 1B includes prefabricated laminated wall panels 6 on the inner leaves, prefabricated laminated wall panels 7 on the outer leaves, FRP insulation connectors 10 connecting the prefabricated wall panels on the inner and outer leaves, and prefabricated laminated wall panels 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com