Weathering resistant steel surface rust layer stabilizing agent and preparing and use method thereof

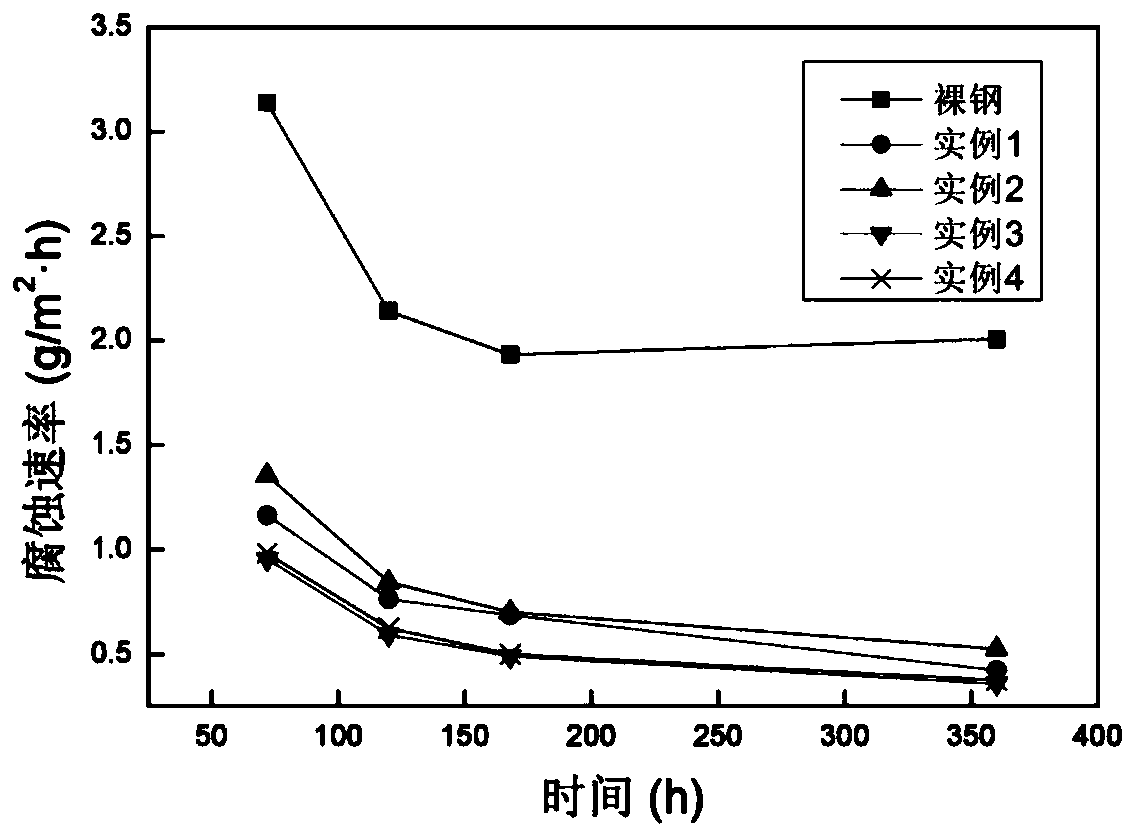

A technology of weathering steel and stabilizer, applied in the direction of metal material coating process, etc., can solve the problems of slow stabilization of rust layer, sag of weathering steel rust liquid, etc., achieve stable and dense rust layer structure, accelerate rust layer stabilization, The effect of reduced generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0067] The present invention also provides a preparation method of a weathering steel surface rust layer stabilizer, comprising the following steps:

[0068] (1) take polyvinyl butyral ester, chromium sulfate, ferric oxide, ferric oxide and ethanol (or ethyl acetate) for subsequent use according to mass percentage;

[0069] (2) First mix and stir the weighed polyvinyl butyral ester, chromium sulfate, ferric oxide, and ferric oxide, and then add solvent ethanol or ethyl acetate, which is conducive to full dissolution and provides convenience for subsequent stirring. Stir thoroughly to obtain a stabilizer with uniform texture. The preparation method of the weathering steel surface rust layer stabilizer of the present invention is simple and low in cost.

[0070] The invention also provides a method for using the stabilizer for the rust layer on the weathering steel surface. The rust layer stabilizer on the weathering steel surface is used to directly treat the weathering steel by...

Embodiment 1

[0076] A rust layer stabilizing treatment agent on the surface of weathering steel, the composition of which is: 2% of polyvinyl butyral ester, 12% of chromium sulfate, 15% of ferric oxide, 20% of ferric oxide, 51% of ethanol %. Ethanol can also be replaced with ethyl acetate.

Embodiment 2

[0078] A rust layer stabilizing agent on the surface of weathering steel, the composition of which is: 10% polyvinyl butyral ester, 5% chromium sulfate, 15% iron sesquioxide, 1% ferric iron tetroxide, 69% ethanol by mass percentage %. Ethanol can also be replaced with ethyl acetate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com