Al-Mg-Si alloy for forging and preparation method of Al-Mg-Si alloy

A forging and alloying technology is applied in the field of the preparation of deformed aluminum alloy materials to achieve the effects of excellent casting performance and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

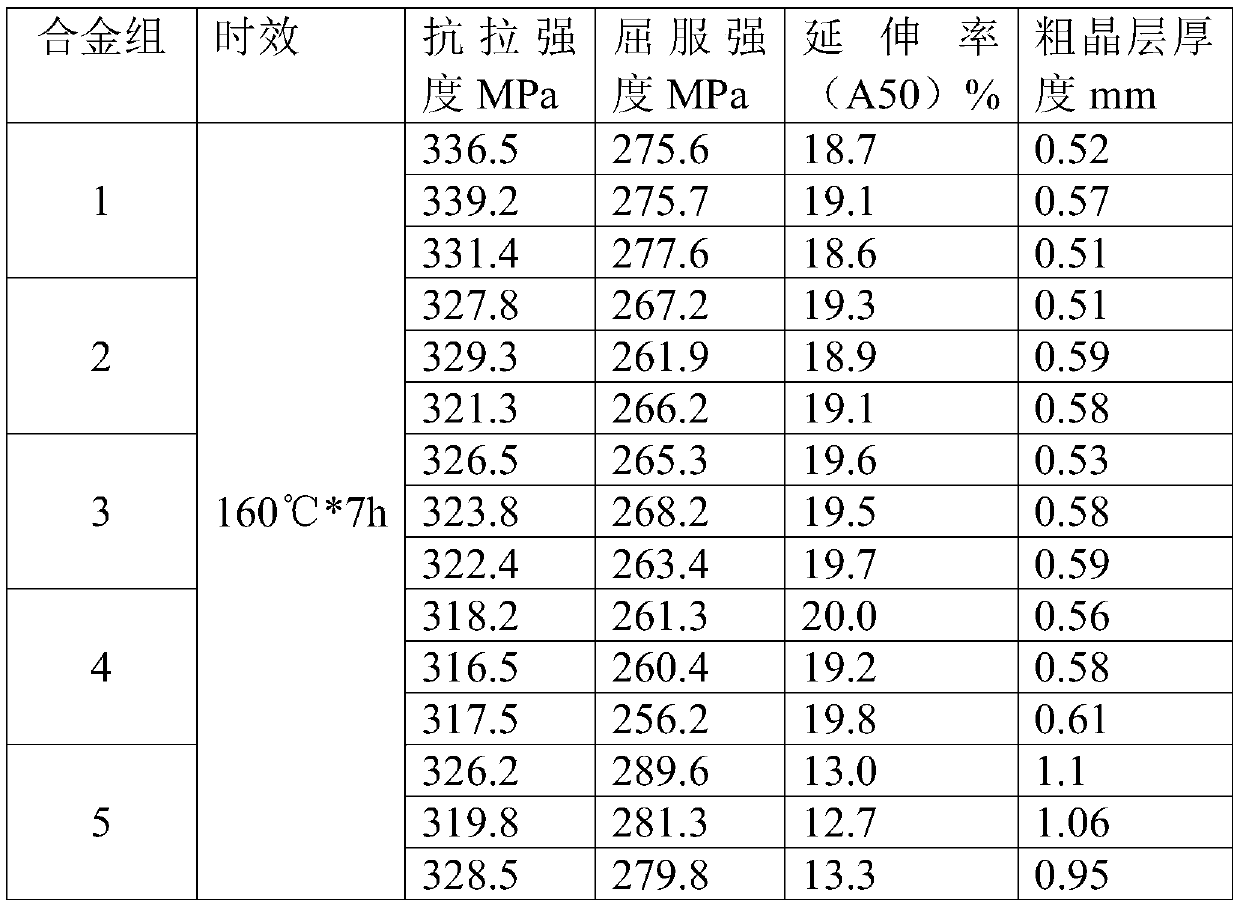

Embodiment 1

[0020] An Al-Mg-Si alloy for forging, the composition of which contains the following elements by mass percentage: silicon 0.841; iron 0.165; copper 0.0961; magnesium 0.839; manganese 0.638; zinc 0.004; chromium 0.0285; titanium 0.0291; the rest is aluminum.

[0021] The preparation method is as follows:

[0022] (1) According to the above composition ratio, the ingredients except for magnesium are charged into a furnace for smelting, and the temperature is 730~780℃;

[0023] (2) According to the component ratio, add magnesium element to the furnace, and mechanically stir for 30 minutes plus electromagnetic stirring for 30 minutes, continue smelting, and slag off at the same time;

[0024] (3) Refining, the temperature is 760~780℃, the time is 30-35min, and the slag is removed simultaneously;

[0025] (4) Casting: the furnace temperature is 765~780℃, the titanium boron wire is fed online, the Hycast online two-stage degassing and slagging, the Hycast low pressure vacuum casting, the cas...

Embodiment 2

[0029] An Al-Mg-Si alloy for forging, the composition of which contains the following elements by mass percentage: silicon 0.795; iron 0.155; copper 0.0772; magnesium 0.801; manganese 0.611; zinc 0.005; chromium 0.0165; titanium 0.0232; the rest is aluminum. The preparation method is the same as in Example 1.

Embodiment 3

[0031] An Al-Mg-Si alloy for forging, the composition of which contains the following elements by mass percentage: silicon 0.803; iron 0.181; copper 0.0802; magnesium 0.792; manganese 0.623; zinc 0.005; chromium 0.0206; titanium 0.0211; the rest is aluminum. The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com