High-production-efficiency polytetramethylene ether glycol preparation method

A polytetramethylene ether glycol and production efficiency technology, which is applied in the field of high production efficiency polytetramethylene ether glycol preparation, can solve the problem that the polymerization efficiency of polytetramethylene ether glycol has not been studied in depth Improvements and other issues to achieve fast and efficient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0071] A method for preparing polytetramethylene ether glycol with high production efficiency, comprising the following steps:

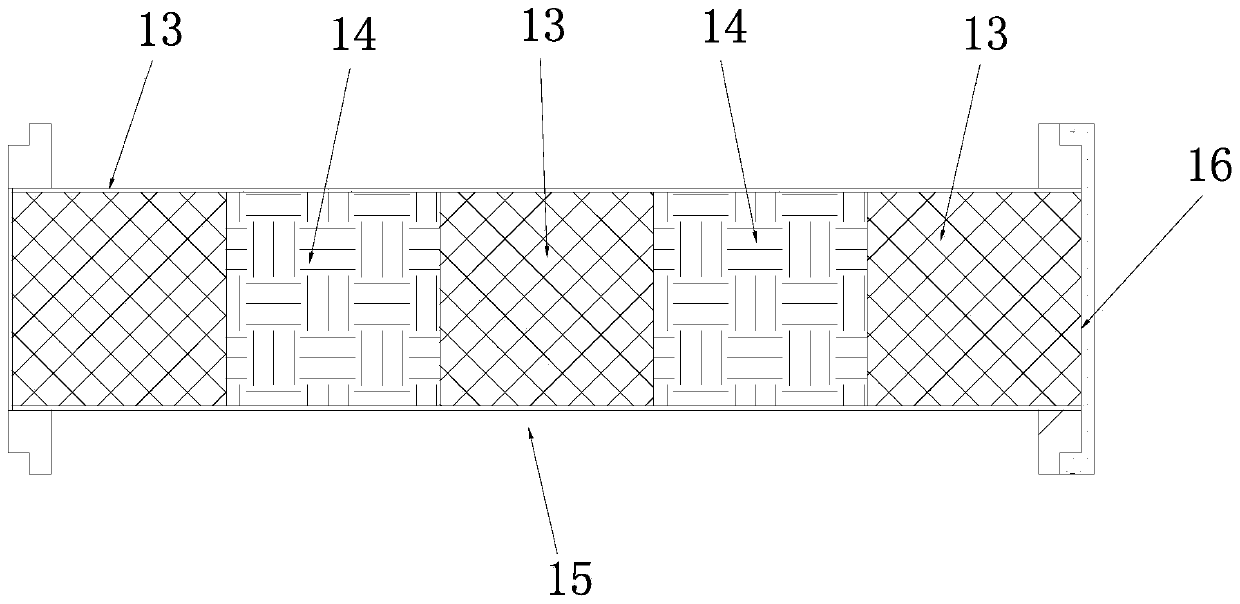

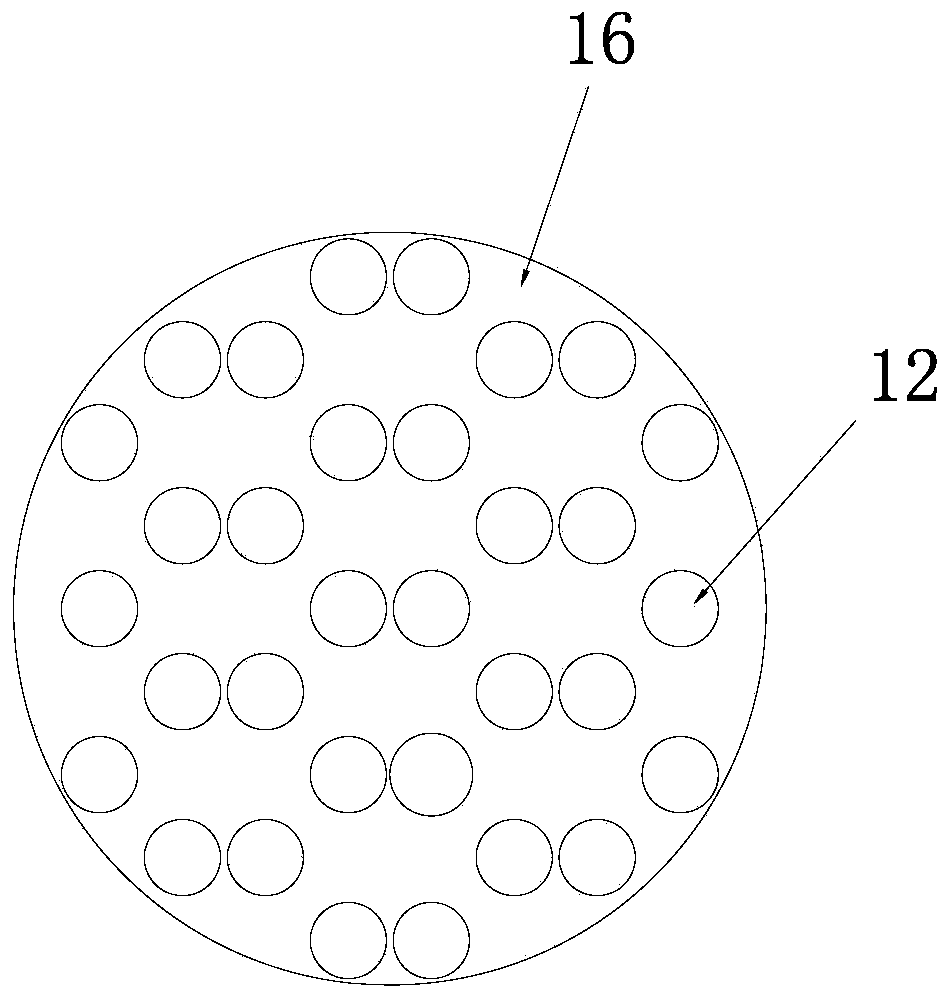

[0072] 1) Thoroughly mix tetrahydrofuran and heteropolyacid catalyst with ether added through an enhanced disperser, and keep the temperature at 50-52°C, then enter the main reactor for polymerization; Section, distribution plate and circulation heat exchange section.

[0073] 2) The catalyst settled in the main reaction kettle is sent out from the bottom of the kettle for recycling, and the obtained reaction solution is discharged from the top of the kettle and then enters the first-stage centrifuge, and most of the catalyst is separated by centrifugation and recycled.

[0074] 3) The remaining reaction liquid enters the first distillation tower to remove most of the tetrahydrofuran and all ether, and the THF content in the obtained concentrated solution is kept at 25 to 35 wt%. machine, the concentration of the extractant in the mixed liquid after...

Embodiment 1

[0092] A method for preparing polytetramethylene ether glycol with high production efficiency, comprising the following steps:

[0093] 1) Thoroughly mix tetrahydrofuran and heteropolyacid catalyst with ether added through an enhanced disperser, and keep the temperature at 50-52°C, then enter the main reactor for polymerization; Section, distribution plate and circulation heat exchange section. The heteropolyacid catalyst is micron-sized phosphotungstic heteropolyacid, and the volume content of the catalyst in the reaction solution is 38%. The ethyl ether content in the tetrahydrofuran is 1.5wt%, the organic phase moisture in the system is 0.3%, and the filling factor of the main reactor is 100%.

[0094] 2) The catalyst settled in the main reaction kettle is sent out from the bottom of the kettle for recycling, and the obtained reaction solution is discharged from the top of the kettle and then enters the first-stage centrifuge, and most of the catalyst is separated by centr...

Embodiment 2

[0101] A method for preparing polytetramethylene ether glycol with high production efficiency, comprising the following steps:

[0102] 1) Thoroughly mix tetrahydrofuran and heteropolyacid catalyst with ether added through an enhanced disperser, and keep the temperature at 50-52°C, then enter the main reactor for polymerization; Section, distribution plate and circulation heat exchange section. The heteropolyacid catalyst is phosphotungstic heteropolyacid, and the volume content of the catalyst in the reaction solution is 35%. The ethyl ether content in the tetrahydrofuran is 1 wt%, and the filling factor of the main reactor is 100%.

[0103] 2) The catalyst settled in the main reaction kettle is sent out from the bottom of the kettle for recycling, and the obtained reaction solution is discharged from the top of the kettle and then enters the first-stage centrifuge, and most of the catalyst is separated by centrifugation and recycled.

[0104] 3) The remaining reaction liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com