A kind of self-healing material and its preparation method and application

A technology of self-repairing material and composite powder, which is applied in the field of concrete materials, can solve the problems that self-repairing materials cannot achieve crack repairing effect, and achieve high practical value and promotion value, good repairing effect and fast repairing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

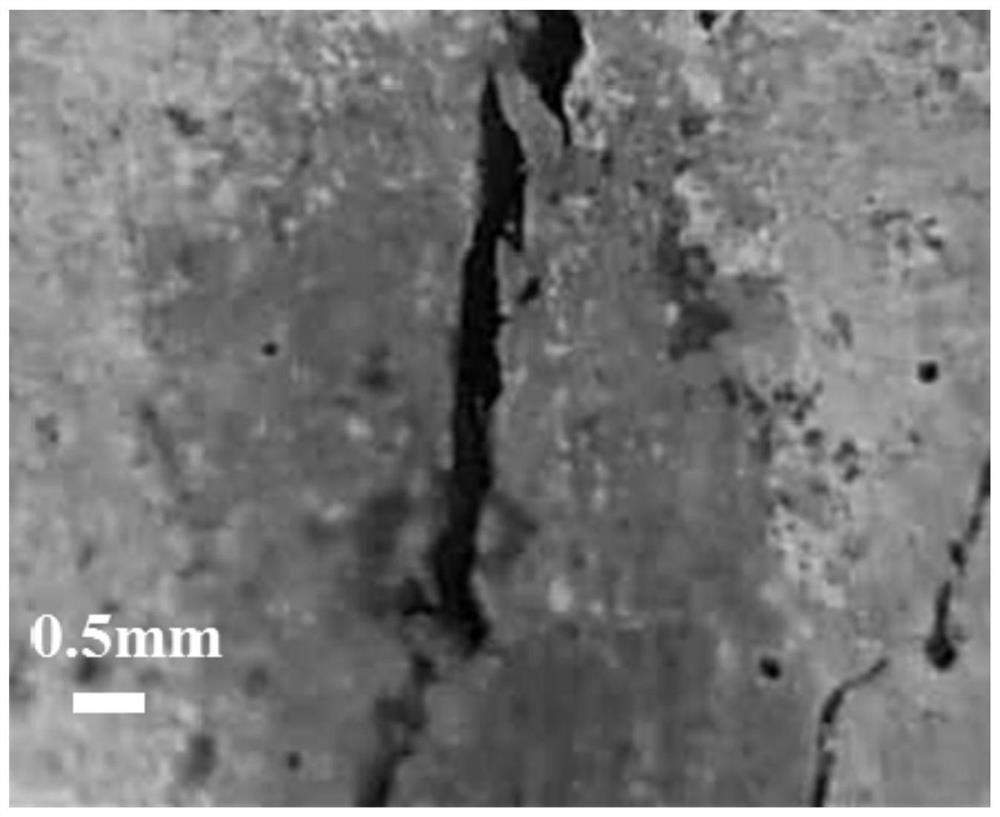

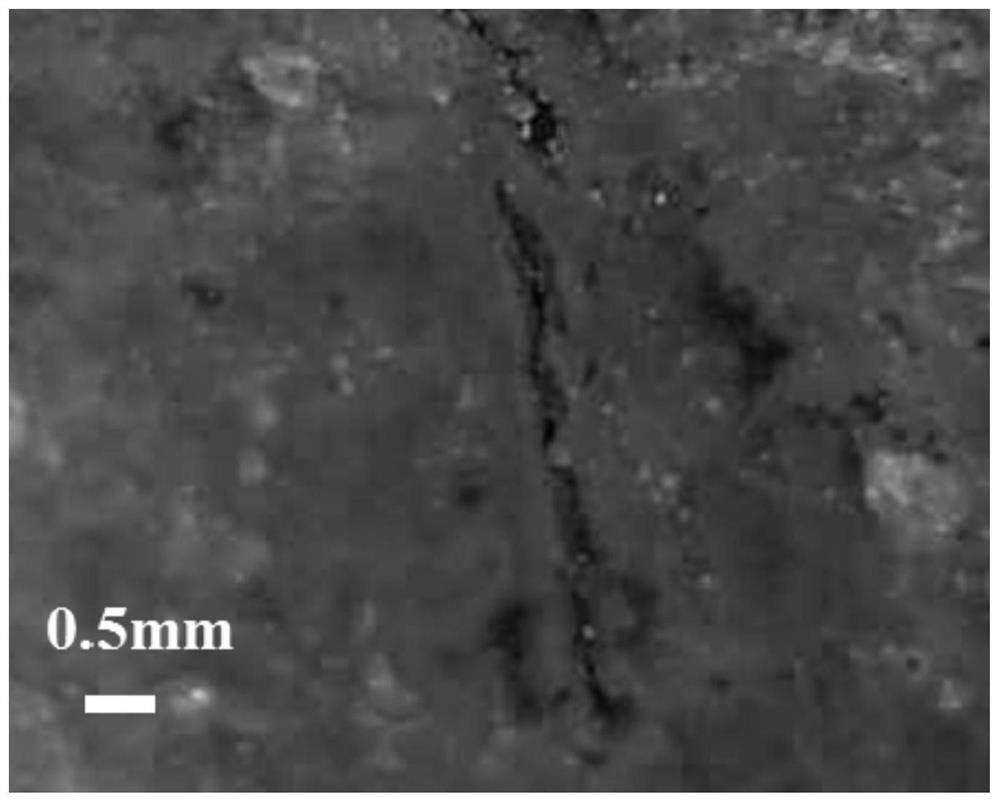

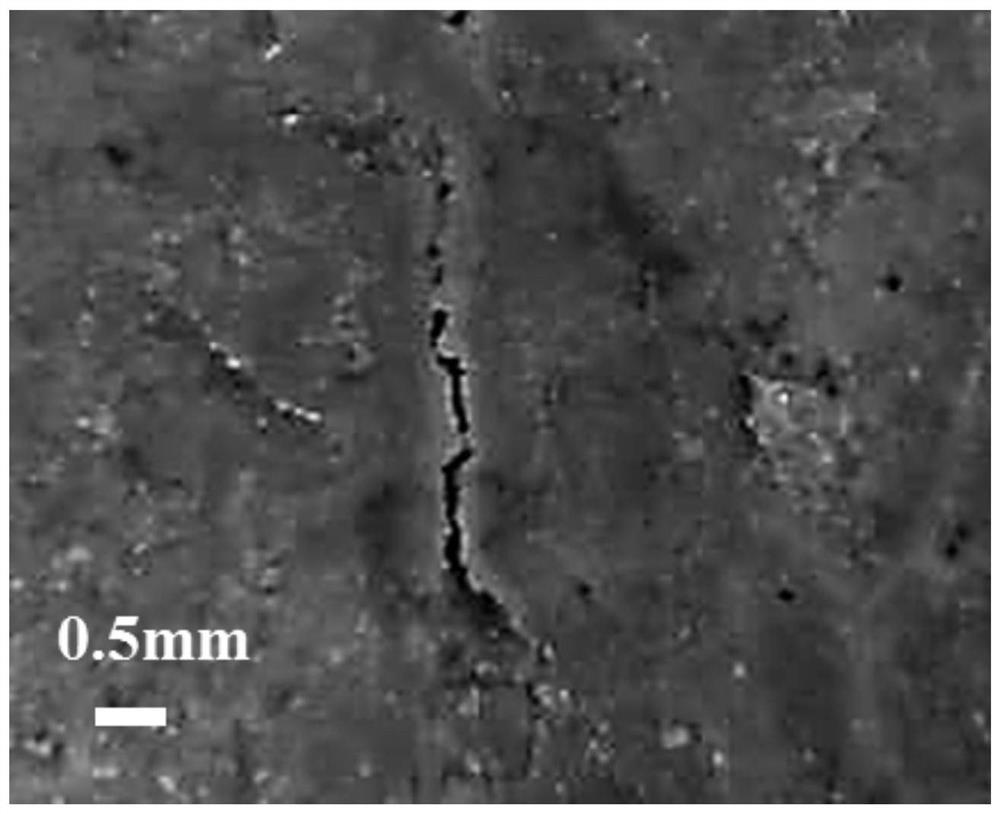

Image

Examples

Embodiment 1

[0040] An embodiment of the present invention provides a microcrack repairing agent for cement-based materials for construction. The raw materials include the following components in parts by mass:

[0041] 15 parts of pumice powder, 55 parts of expansion component, 5 parts of lithium carbonate, 15 parts of potassium carbonate, 10 parts of PVB.

[0042] The preparation method of the above-mentioned cement-based material microcrack repairing agent for construction comprises the following steps:

[0043] Step 1. Weigh each component according to the designed ratio, and mix the weighed reinforcement component and expansion component uniformly to obtain composite powder;

[0044] Step 2. Stir the composite powder and pumice powder for 3 hours under the condition of 700r / min to obtain a primary coating repair powder;

[0045] Step 3: adding the weighed polyvinyl butyral into ethanol, heating to 60°C for 30 minutes to obtain a slow-release solution;

[0046] Step 4. Stir the primary...

Embodiment 2

[0048] An embodiment of the present invention provides a microcrack repairing agent for cement-based materials for construction. The raw materials include the following components in parts by mass:

[0049] 10 parts of pumice powder, 40 parts of expansion component, 6 parts of lithium carbonate, 24 parts of potassium bicarbonate, 20 parts of PVB.

[0050] The preparation method of the above-mentioned cement-based material microcrack repairing agent for construction comprises the following steps:

[0051] Step 1. Weigh each component according to the designed ratio, and mix the weighed reinforcement component and expansion component uniformly to obtain composite powder;

[0052] Step 2. Stir the composite powder and pumice powder for 2 hours under the condition of 900 r / min to obtain a primary coating repair powder;

[0053] Step 3: Add the weighed polyvinyl butyral into ethanol, heat to 65°C for 30 minutes to obtain a slow-release solution;

[0054] Step 4. Stir the primary ...

Embodiment 3

[0056] An embodiment of the present invention provides a microcrack repairing agent for cement-based materials for construction. The raw materials include the following components in parts by mass:

[0057] 10 parts of pumice powder, 50 parts of expansion component, 20 parts of potassium carbonate, 10 parts of potassium bicarbonate, 10 parts of PVB.

[0058] The preparation method of the above-mentioned cement-based material microcrack repairing agent for construction comprises the following steps:

[0059] Step 1. Weigh each component according to the designed ratio, and mix the weighed reinforcement component and expansion component uniformly to obtain composite powder;

[0060] Step 2. Stir the composite powder and pumice powder for 2 hours under the condition of 800r / min to obtain a primary coating repair powder;

[0061] Step 3: Add the weighed polyvinyl butyral into ethanol, heat to 62°C for 30 minutes to obtain a slow-release solution;

[0062] Step 4. Stir the primar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com