Treatment method of arsenic-fluorine-containing industrial wastewater

A technology for industrial waste water and treatment methods, which is applied in water/sewage treatment, neutralized water/sewage treatment, multi-stage water/sewage treatment, etc. It can solve the problems of poor water quality adaptability, complex treatment process, and many types and quantities of chemicals used. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

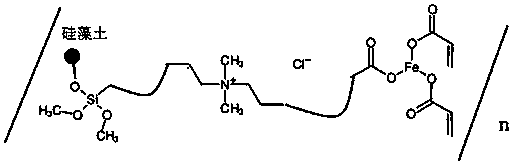

Image

Examples

Embodiment 1

[0036] A treatment method for industrial wastewater containing arsenic and fluorine, the specific preparation scheme is as follows:

[0037] Step 1. Acidification treatment, add acidulant to the original wastewater, adjust the pH of the wastewater to 2, use compressed air to bubble and stir for 10 minutes, with a flow rate of 30m 3 / h, after mixing evenly, let it stand, and then the waste water enters the pipeline mixer;

[0038] Step 2: Adding reagent, the wastewater enters the pipeline mixer to add the reagent, the addition amount is 300g / m 3 , Reaction time 20min, flow velocity 35m 3 / h;

[0039] Step three, alkalization treatment, add alkalization agent to the wastewater, adjust the pH value of the wastewater to 6, use compressed air to bubble and stir for 5 minutes, the flow rate is 30m 3 / h, after stirring evenly, let it stand, and then the wastewater enters the sedimentation tank;

[0040] Step 4: Settling and separation, the flow of wastewater is controlled to 3m after entering...

Embodiment 2

[0051] A treatment method for industrial wastewater containing arsenic and fluorine, the specific preparation scheme is as follows:

[0052] Step 1. Acidification treatment, add acidifier to the original wastewater, adjust the pH of the wastewater to 4, use compressed air to bubble and stir for 8 minutes, with a flow rate of 50m 3 / h, after mixing evenly, let it stand, and then the waste water enters the pipeline mixer;

[0053] Step 2: Adding reagent, the wastewater enters the pipeline mixer to add the reagent, the addition amount is 500g / m 3 , Reaction time 40min, flow velocity 60m 3 / h;

[0054] Step 3. Alkalizing treatment, adding an alkalizing agent to the wastewater, adjusting the pH of the wastewater to 7, using compressed air to bubbling and stirring for 8 minutes, with a flow rate of 40m 3 / h, after stirring evenly, let it stand, and then the wastewater enters the sedimentation tank;

[0055] Step 4: Settling and separation, the flow of wastewater is controlled to 5m after ent...

Embodiment 3

[0066] A treatment method for industrial wastewater containing arsenic and fluorine, the specific preparation scheme is as follows:

[0067] Step 1. Acidification treatment, add acidulant to the original wastewater, adjust the pH of the wastewater to 5, use compressed air to bubble and stir for 5 minutes, with a flow rate of 60m 3 / h, after mixing evenly, let it stand, and then the waste water enters the pipeline mixer;

[0068] Step 2: Adding agent, the wastewater enters the pipeline mixer to add the reaction agent, the addition amount is 800g / m 3 , Reaction time 60min, flow rate 80m3 / h;

[0069] Step 3. Alkalizing treatment, adding an alkalizing agent to the wastewater, adjusting the pH of the wastewater to 8, using compressed air to bubbling and stirring for 10 minutes, with a flow rate of 60m 3 / h, after stirring evenly, let it stand, and then the wastewater enters the sedimentation tank;

[0070] Step 4: Settling and separation, the flow of wastewater is controlled to 7m after ent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com