Fluorine-containing wastewater treatment method

A treatment method and technology for wastewater, applied in water/sewage treatment, neutralized water/sewage treatment, water/sewage multi-stage treatment, etc., can solve problems such as inability to treat fluorine pollution in depth, achieve low pH requirements, and have a wide range of applications , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Take fluorine-containing wastewater from a copper smelter, its pH=6.36, and its fluorine content is 21.68mg / L.

[0028] Modification of strong basic anion resin D301:

[0029] Firstly wash the strongly basic anion resin with clear water for 20-30 minutes, wash it 2-3 times, then use 5wt% hydrochloric acid to shake and activate the strong basic anion resin for 1-2 hours; then use 5wt% sodium hydroxide solution to The strong basic anion resin is shaken and activated for 1 to 2 hours; rinsed with water to neutrality, and finally the strong basic anion resin is modified with a modifying solution to obtain the modified strong basic anion resin for use. The modifying solution is a 10wt% mixed solution prepared by compounding 90% aluminum sulfate and 10% lanthanum nitrate.

[0030] The specific processing process is:

[0031] (1) Since the pH of the raw water of fluorine-containing wastewater is within the scope of the present invention, there is no need to call back;

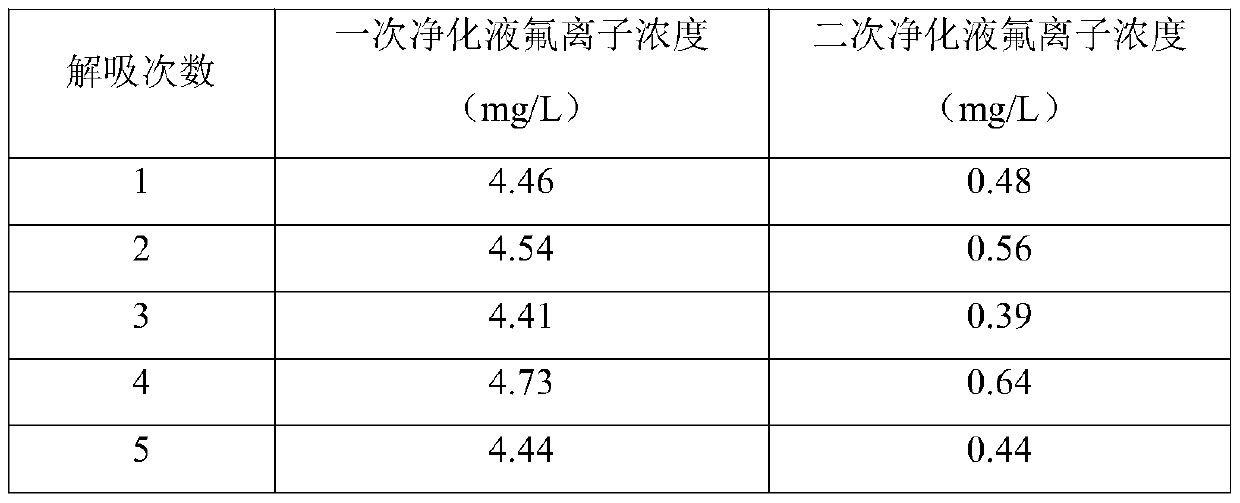

[00...

Embodiment 2

[0042] Take fluorine-containing wastewater from a copper smelter, its pH=10.14, and its fluorine content is 13.8mg / L.

[0043] Modification of strong basic anion resin 201:

[0044] First, wash the strongly basic anion resin with clear water for 20-30 minutes and wash it for 2-3 times, then use 5wt% sulfuric acid to vibrate and activate the strong basic anion resin for 1-2 hours; then use 5wt% sodium carbonate solution to The anion resin is vibrated and activated for 1-2 hours; rinsed with clear water until neutral, and finally modified with 10wt% polyaluminum chloride solution to obtain the modified strongly basic anion resin for use.

[0045]The specific processing process is:

[0046] (1) Due to the high pH of the raw water of fluorine-containing wastewater, first use 10wt% dilute sulfuric acid to adjust it to 6.5;

[0047] (2) Add 0.5g / L chemical defluorinating agent to the fluorine-containing wastewater, and stir for 15 minutes. The chemical defluorinating agent is comp...

Embodiment 3

[0052] Take fluorine-containing wastewater from a copper smelter, its acidity is 0.1mol / L, and the fluorine content is 53.64mg / L.

[0053] Modification of strong basic anion resin D301:

[0054] Firstly wash the strongly basic anion resin with clean water for 20-30 minutes, and wash it for 2-3 times, then use 5wt% sodium hydroxide solution to activate the strong basic anion resin for 1-2 hours; The modified strongly basic anion resin is prepared by modifying the strong anion resin, and the modified solution is a 10wt% solution compounded by 70% aluminum chloride and 30% lanthanum chloride.

[0055] The specific processing process is:

[0056] (1) Due to the high acidity of the raw water of fluorine-containing wastewater, sodium hydroxide is added to adjust the pH to 5;

[0057] (2) Add 2g / L chemical defluorinating agent to fluorine-containing wastewater, and stir for 20 minutes. The chemical defluorinating agent is a 30wt% solution prepared by combining 80% aluminum nitrate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com