Filling material and filling method

A technology of filling materials and filling methods, applied in metal processing equipment, maintenance and safety accessories, metal processing machinery parts, etc., can solve problems such as inability to complete product delivery, affect scientific research and production progress, and process technology bottlenecks, etc., to reduce cutting vibration Phenomenon, reducing parts deformation, avoiding the effect of high temperature deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment, but should not be interpreted as that the scope of the subject matter of the present invention is only limited to following embodiment, under the situation of not departing from above-mentioned technical thought of the present invention, all according to this field Various modifications, substitutions and alterations made by ordinary technical knowledge and common means are included in the scope of the present invention.

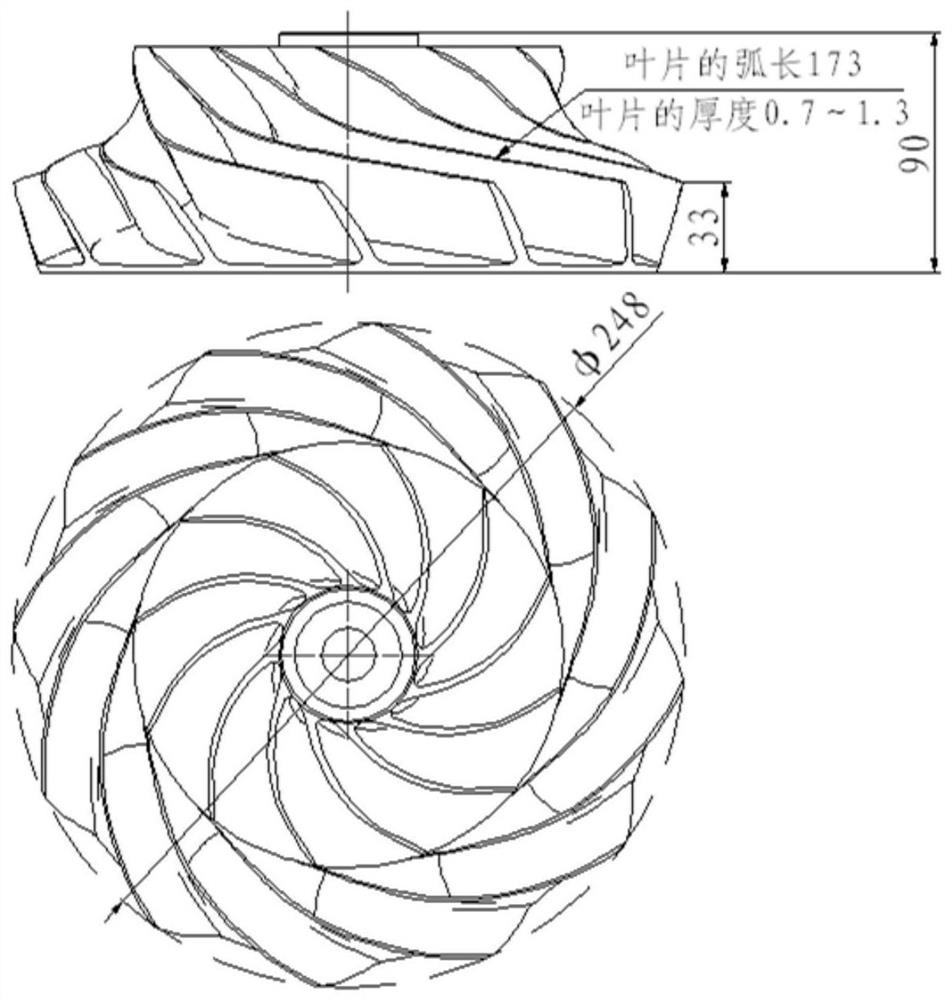

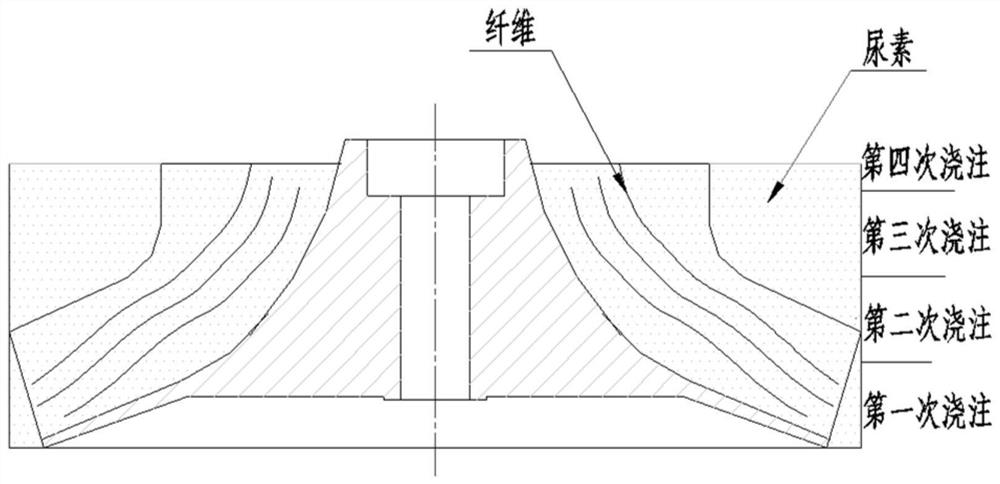

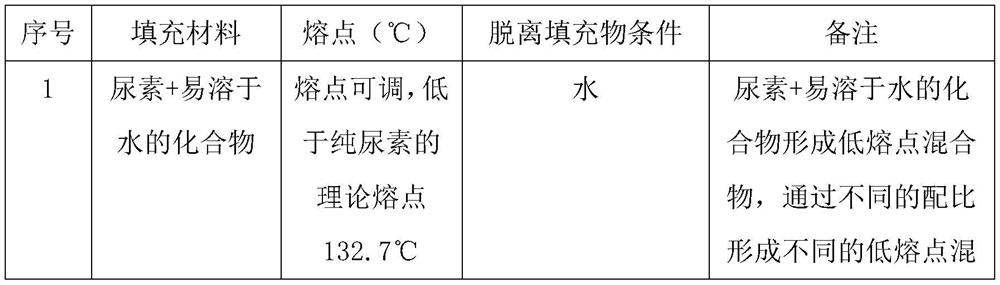

[0026] like figure 1 As shown, the fan impeller needs to be cut. In this embodiment, filling materials are used to fill the gap between thin-walled blades and thin-walled blades in the fan impeller structure to form an integrated solid structure. Solve the problems of excessive dimensional deformation and unqualified product surface roughness that are easy to occur in the existing mechanical cutting process.

[0027] First of all, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com