Heating device and method for large-diameter thick-wall pipe

A technology of a heating device and a heating method, which is applied in the field of pipe bending, can solve the problems that the circumferential deformation of the steel pipe is not considered, and the quality of the pipe blank is difficult to be effectively solved, so as to achieve the effect of optimizing the distribution of the temperature field and improving the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to detail the technical content, structural features, achieved goals and effects of the present invention, the following will be described in detail in conjunction with the accompanying drawings.

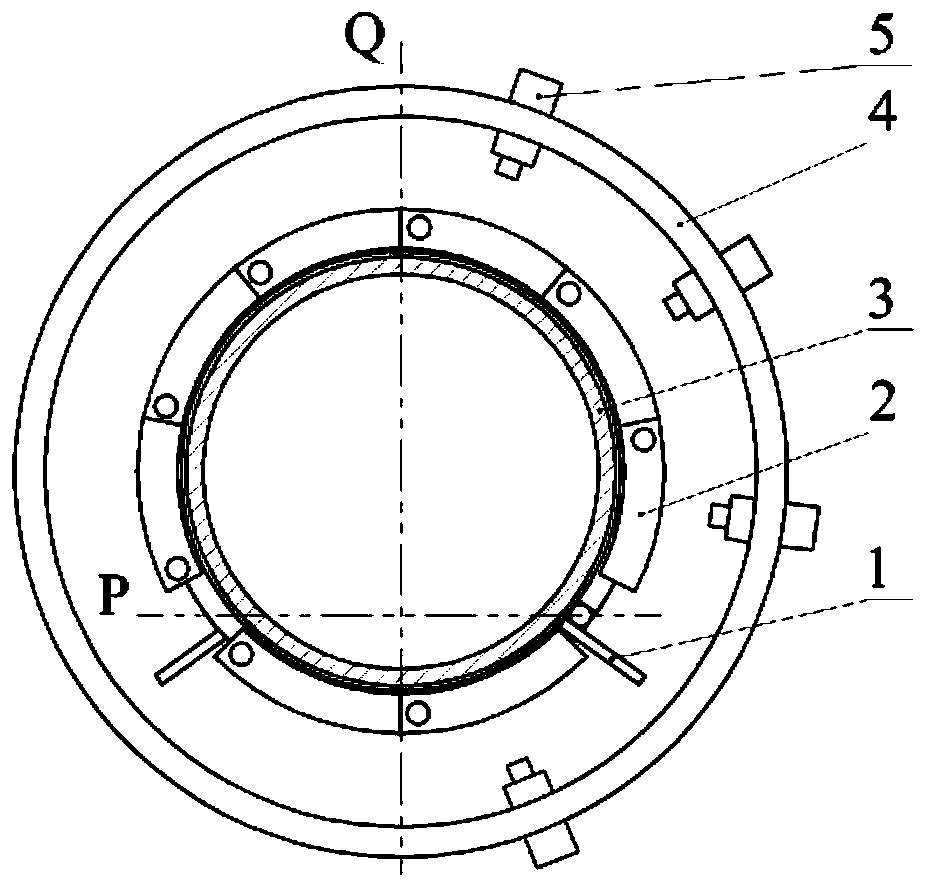

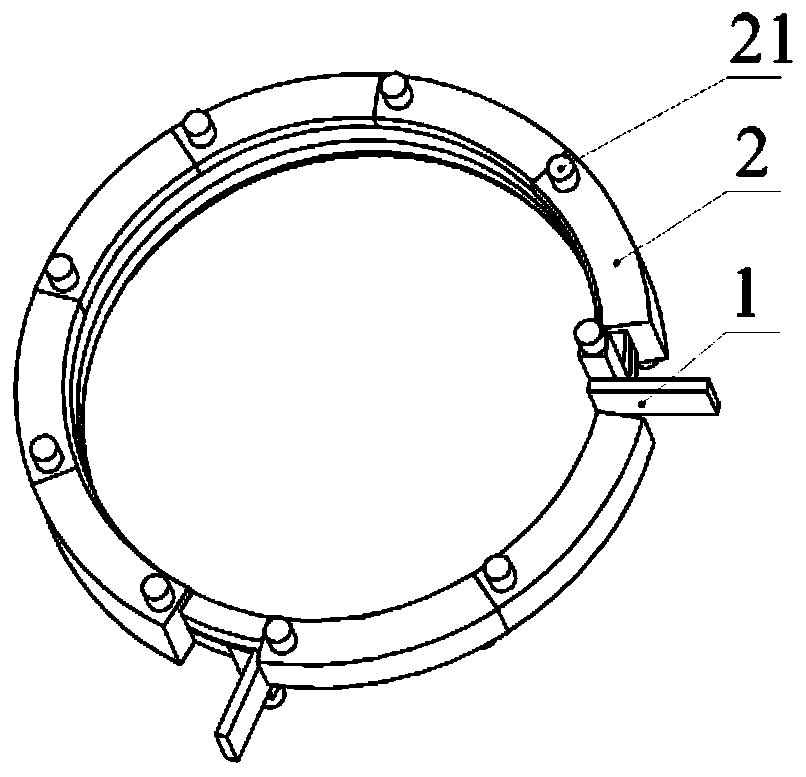

[0041] Heating devices for large-diameter thick-walled pipes, such as figure 1 As shown, it includes an induction coil 1 , a magnetizer 2 , a target tube blank 3 , a bracket 4 , an infrared thermometer 5 and a liquid pressure controller 7 .

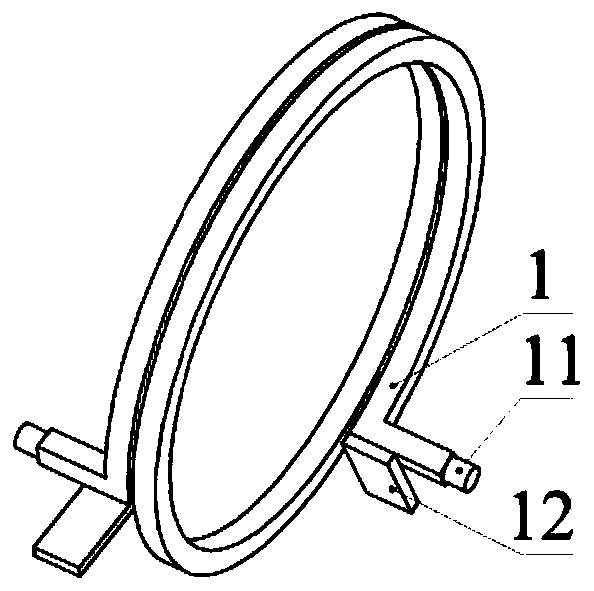

[0042] Such as figure 2As shown, the shape of the induction coil 1 is a spiral structure wound by a rectangular hollow copper tube, and the outer surface is coated with an insulating layer. The two ends of the induction coil 1 are respectively provided with a water inlet and outlet 11 and a terminal block 12. The water inlet and outlet 11 are used for The induction coil 1 is cooled by cooling water during the working process, and the terminal board 12 is used for connecting an external power supply. The diameter of the helix ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com