Sulfur ion concentration detection method

A detection method, sulfide ion technology, applied in the preparation of test samples, measurement of color/spectral characteristics, electrochemical variables of materials, etc., can solve the problems of high time cost, complicated operation, high detection cost, etc., and achieve low limit determination Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

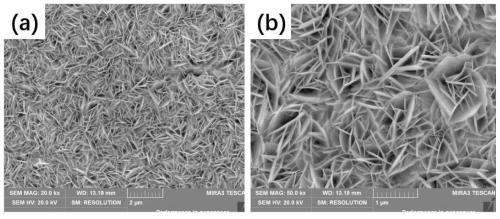

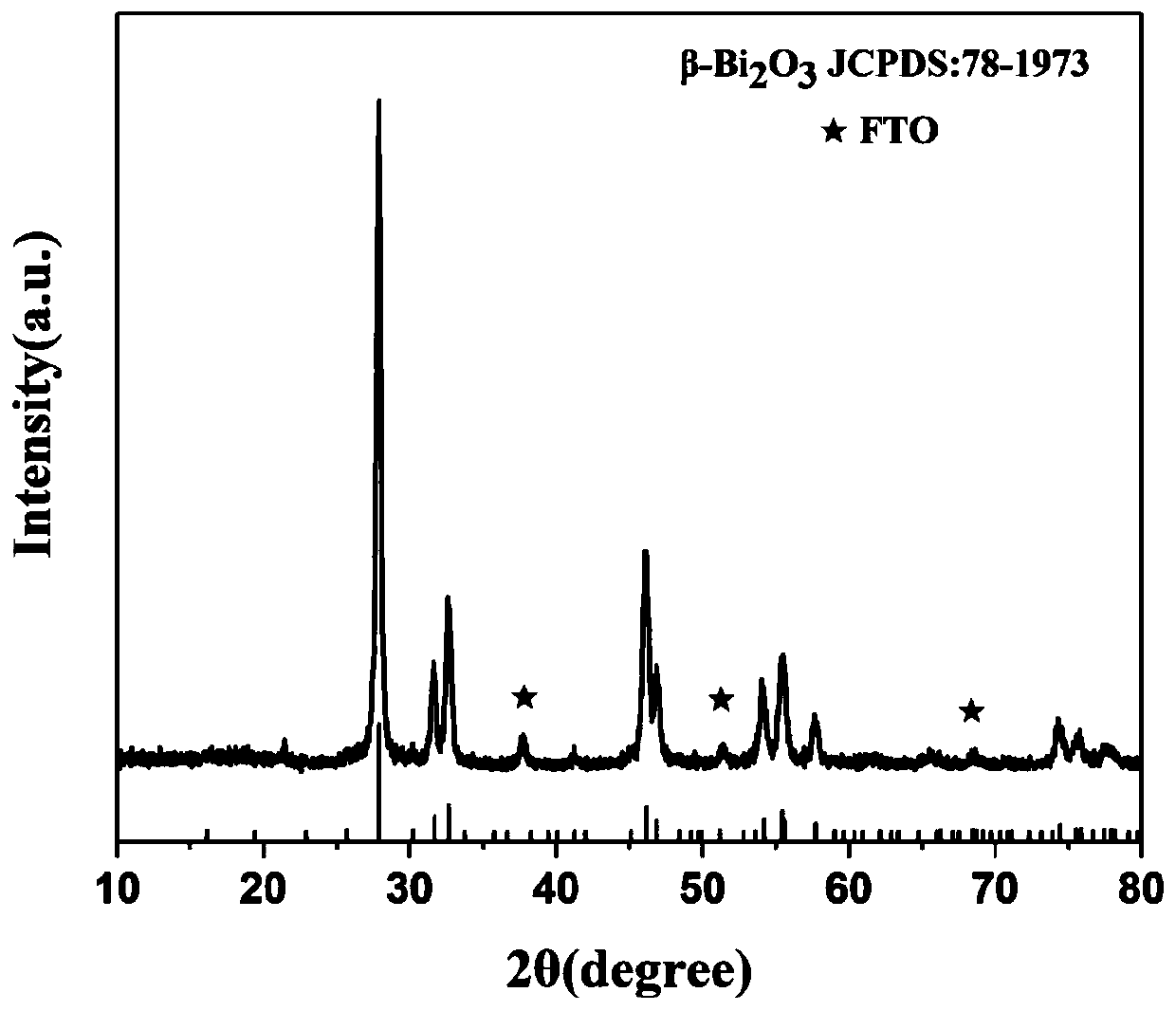

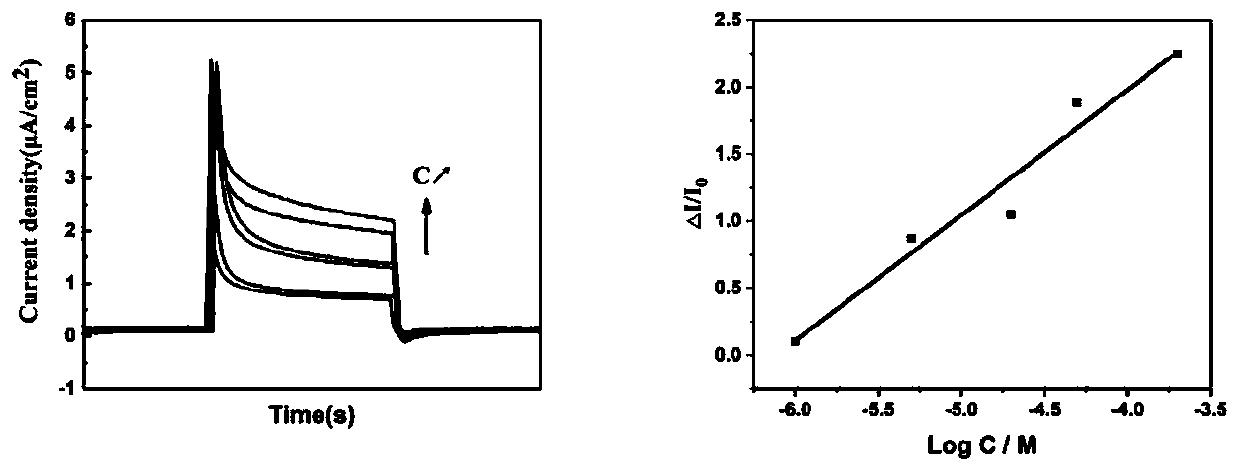

[0073] Bi 2 o 3 Fabrication of Thin Film Electrode and Its Photoelectrochemical Detection of Sulfur Ion Concentration in Water

[0074] The method for rapid photoelectrochemical detection of sulfur ion concentration in water body provided by Embodiment 1 of the present invention uses a chemical water bath method to deposit Bi 2 o 3 Taking the thin film as the working electrode as an example, it mainly includes the following steps:

[0075] (1) Preparation of photoelectric sensing electrodes

[0076] ① Pretreatment of conductive substrate

[0077] Cut the FTO into 2cm*3cm size, after cleaning with surfactant, ultrasonic cleaning with ultrapure water, ethanol, acetone, and ultrapure water respectively for 15min, and N 2 It was blown dry, and then cleaned with a surface plasma cleaner for 5 minutes.

[0078] ② Preparation of photoelectric sensing electrode materials

[0079] Weigh 2.91g of bismuth nitrate in a beaker, add 2mL of concentrated nitric acid to it, and then add...

Embodiment 2

[0091] Bi 2 o 2.33 Fabrication of Thin Film Electrode and Its Photoelectrochemical Detection of Sulfur Ion Concentration in Water

[0092] A method for detecting the concentration of sulfur ions in water, depositing Bi with a chemical water bath method 2 o 2.33 Taking the thin film as the working electrode as an example, it mainly includes the following steps:

[0093] (1) Preparation of electrodes

[0094] ① Pretreatment of conductive substrate

[0095] Cut the ITO to a size of 5cm*5cm, wash it with a surfactant, and then ultrasonically clean it with ultrapure water, ethanol, acetone, and ultrapure water for 15 minutes, and wash it with N 2 It was blown dry, and then cleaned with a surface plasma cleaner for 5 minutes.

[0096] ② Preparation of precursor solution

[0097] A certain amount of nitric acid was slowly added to 4 mL of deionized water to obtain liquid A, and then 1 g of bismuth nitrate was added. Under continuous stirring, add a certain amount of Triton X-...

Embodiment 3

[0111] Bi 2 o 3 Preparation of thin film electrode and its visual colorimetric detection of sulfur ion concentration in water

[0112] In the method for rapid visual colorimetric detection of sulfur ion concentration in water body provided by Embodiment 1 of the present invention, Bi is deposited by a chemical water bath method. 2 o 3 Taking the thin film as the working electrode as an example, it mainly includes the following steps:

[0113] (1) Preparation of film

[0114] ①Pretreatment of non-conductive substrates

[0115] Cut the glass into 2cm*3cm size, wash it with surfactant, then ultrasonically clean it with ultrapure water, ethanol, acetone, and ultrapure water for 15 minutes respectively, and wash it with N 2 It was blown dry, and then cleaned with a surface plasma cleaner for 5 minutes.

[0116] ②Preparation of film materials

[0117]Weigh 2.91g of bismuth nitrate in a beaker, add 2mL of concentrated nitric acid to it, and then add deionized water to prepare ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com