A kind of preparation method of elastic denim fabric covered with linen spandex

A technology for covering spandex and denim fabrics, applied in textile, yarn, textile and papermaking, etc., can solve the problems of not fully exerting the elastic recovery ability of elastic fiber filament, and the connection between flax fiber and elastic fiber filament is not very stable, etc. , to achieve uniform elastic recovery performance, improve bonding effect, and uniform voids.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

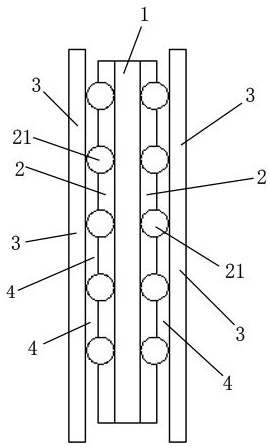

[0021] The content of the present invention will be described in further detail below with reference to the accompanying drawings.

[0022] A preparation method of a flax-coated spandex elastic denim fabric, the steps are as follows:

[0023] S1. Flax treatment: select the raw hemp with a splitting index greater than or equal to 250, and beat the raw hemp into hemp; spray the hemp with an aqueous solution containing a wetting agent for humidification; The roving is spun into rovings on a drawing frame; the rovings are sequentially subjected to compound enzyme degumming treatment, storage, acid washing, sub-bleaching, alkali washing, oxygen bleaching, and water washing; the rovings are twisted by a spinning frame to make spun yarns; the flax Spinning yarn for drying and winding; moisturizing for 18-36 hours; a total of 5 draw frames; four enzymes, pectinase, lipase, xylanase, and virilase, are compounded in a ratio of 3:2:1:1 Then, through tertiary fermentation, a degumming en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com