Antistatic fabric

A technology of antistatic and antistatic additives, applied in the field of fabrics, can solve problems such as the decline of antistatic ability, the impact of processing and product quality, and incomplete infiltration, and achieve the effect of accelerated discharge rate and low resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

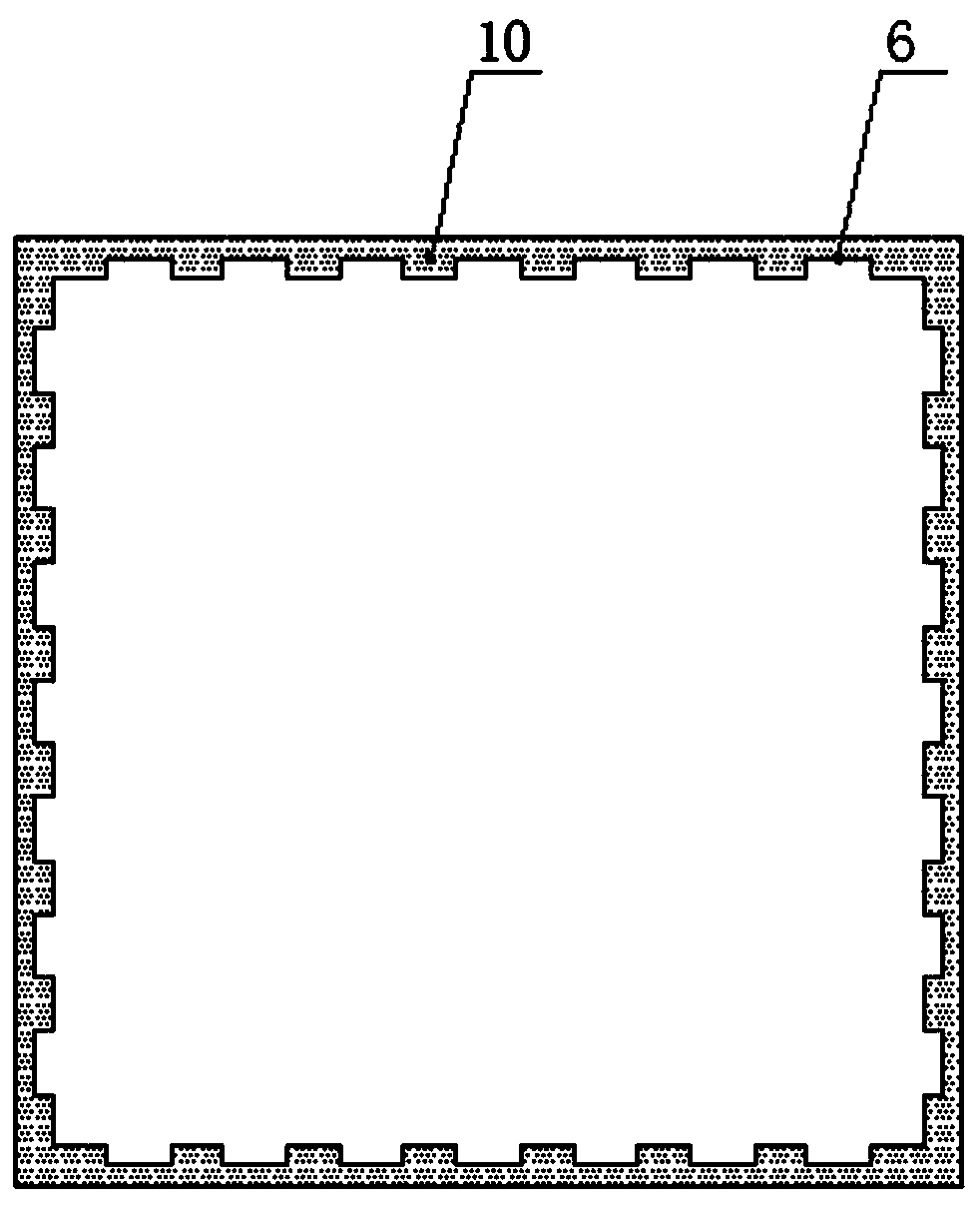

Image

Examples

Embodiment 1

[0031] An antistatic fabric, each raw material is respectively 45% polyester fiber, 20% cotton fiber, 20% silk fiber, 7.5% aluminum fiber and 7.5% graphite fiber by weight percentage;

[0032] The antistatic fabric is prepared according to the following steps:

[0033] 1) Raw material removal treatment: firstly remove the particulate impurities mixed in polyester fiber, cotton fiber, silk fiber, aluminum fiber and graphite fiber by hand, then loosen them by hand and put them into an ultrasonic cleaning machine for cleaning , and the working frequency is controlled at 25KHz, and the cleaning time is controlled at 30 minutes, then it is taken out and put into a drying room at 60 degrees for drying to obtain clean and fluffy fibers;

[0034] 2) Blending processing: the clean and fluffy fibers obtained in step 1) are drawn, roved and spun to obtain spun yarns, and then the spun yarns are wound on the warp beam and coil of the shuttle loom respectively. Then, the warp yarn on the ...

Embodiment 2

[0042] An antistatic fabric, each raw material is respectively 50% polyester fiber, 25% cotton fiber and 25% silk fiber by weight percentage;

[0043] The antistatic fabric is prepared according to the following steps:

[0044] 1) Raw material removal treatment: first remove the particulate impurities mixed in polyester fiber, cotton fiber and silk fiber by hand, then loosen them by hand and put them into an ultrasonic cleaning machine for cleaning, and the working frequency is controlled at 25KHz, the cleaning time is controlled at 30 minutes, then take it out and put it in a drying room at 60 degrees for drying to get clean and fluffy fibers;

[0045] 2) Blending processing: the clean and fluffy fibers obtained in step 1) are drawn, roved and spun to obtain spun yarns, and then the spun yarns are wound on the warp beam and coil of the shuttle loom respectively. Then, the warp yarn on the warp beam and the weft yarn on the reel are interwoven by the shuttle on the shuttle lo...

Embodiment 3

[0052] A kind of antistatic fabric, with embodiment 1.

[0053] The antistatic fabric is prepared according to the following steps: the same as in Example 1.

[0054]Wherein, the preparation method of the modified antistatic auxiliary agent in step 4) is as follows: first, after the reaction kettle is preheated to 100 degrees and kept for 5 minutes, lauryl alcohol and sodium hydroxide are added thereto, and it is mixed and stirred at this temperature. Afterwards, vacuumize and dehydrate until the anhydrous distills out in the reactor, and inject nitrogen to remove the residual air in the reactor, then feed ethylene oxide into it, pressurize to 0.15Mpa, and control the reaction temperature at 150 After reacting for 120 minutes, cool the obtained feed liquid to 90 degrees, then filter it with a 100-mesh stainless steel sieve while it is still hot, and then neutralize the filtrate with potassium hydroxide aqueous solution, let it stand and cool to obtain a modified antistatic Au...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com