Steelmaking operation method adopting steel scrap crushed material to replace cooling agent

An operation method and crushing material technology, which are applied in the manufacture of converters, etc., can solve the problems of increased slag in the furnace, increased consumption of steel materials, increased production costs, etc., and achieve the goals of reducing molten iron consumption, reducing metal loss, and increasing production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

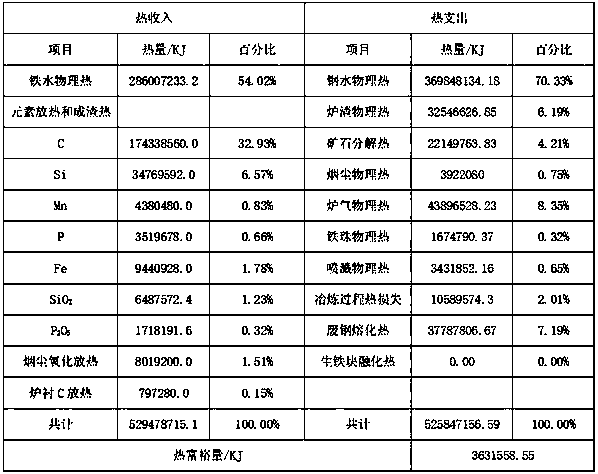

[0012] A steelmaking operation method in which steel scrap crushed material replaces coolant. The steps are as follows: process medium-sized scrap steel into crushed material by crushing, and at the same time require the specific gravity of the crushed material pile to be greater than 1.60t / m3, and transport it to the high-level silo of the converter; Calculate the heat required for melting 1kg of crushed material for scrap steel melting, and determine the amount of crushed material added according to the heat surplus in the furnace: Q scrap steel = m scrap steel × {C solid (t melting - t initial) + melting latent heat of scrap steel + C liquid • (tout-tmelt)}; the cooling effect of 1kg scrap steel when the tapping temperature is 1670°C is: Q scrap steel = 1441.97kJ / kg, the composition and temperature input heat balance calculation model of each furnace of molten iron, using high-level silo to add Crushed material to balance excess heat in the furnace.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com