Anti-yellowing zero-VOC quick-drying bright varnish and preparation method thereof

A technology of anti-yellowing and clear topcoat, applied in the direction of coating, etc., can solve problems affecting production efficiency and delivery period, affecting coating effect, polluting the atmospheric environment, etc., achieve excellent scratch resistance performance, improve production environment, Good effect of construction tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

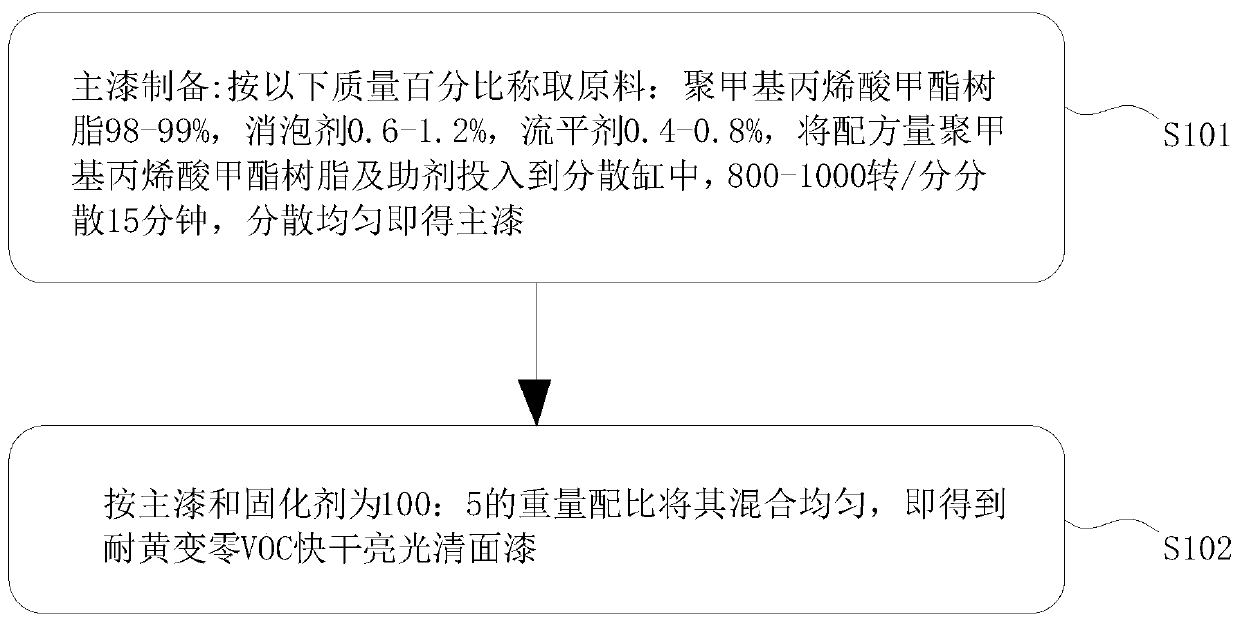

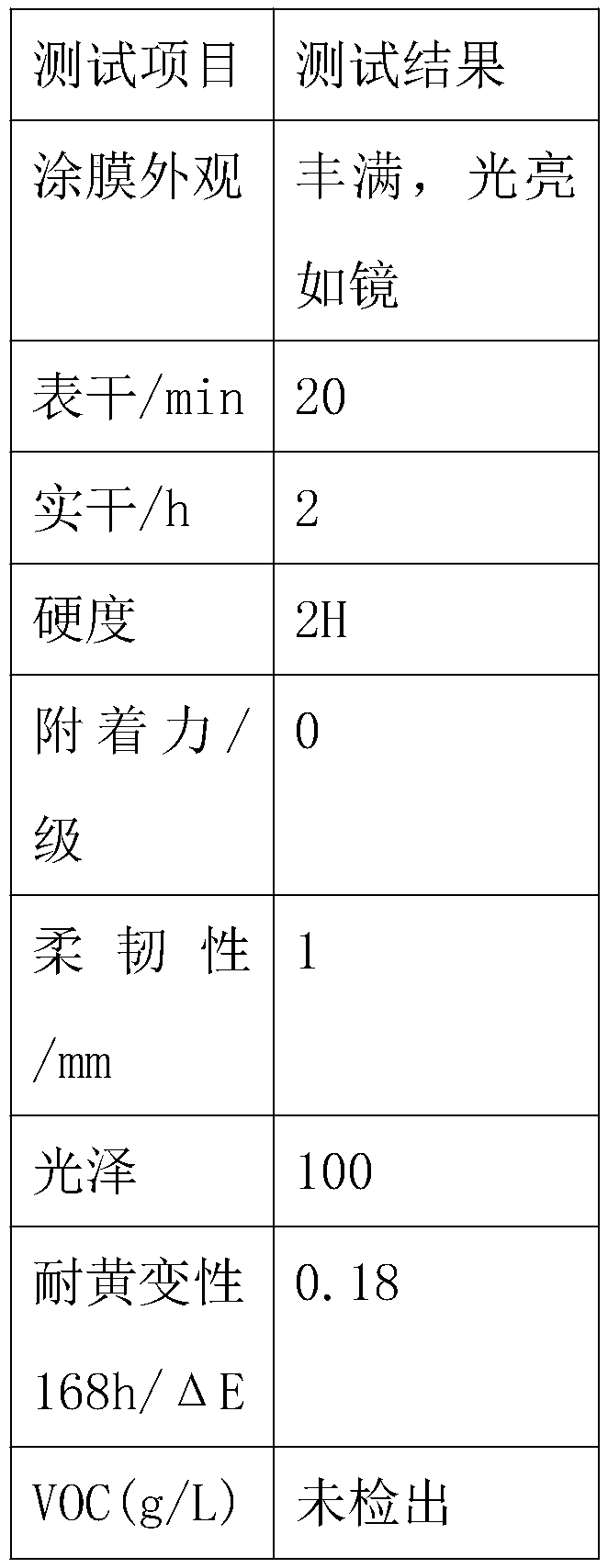

[0023] refer to figure 1 , an anti-yellowing zero VOC quick-drying glossy clear finish paint, including main paint and curing agent, the main paint and curing agent are composed of a ratio of 100:5 by mass, wherein the curing agent is benzoyl peroxide , the main paint is composed of the following components by mass percentage: polymethyl methacrylate resin 98%, defoamer 1.2%, leveling agent 0.8%; among them, the solid content of the yellowing-resistant zero-VOC quick-drying bright clear topcoat 100%; polymethyl methacrylate resin is Degaroute 465 resin, which is a small molecular substance with extremely low viscosity, can quickly and effectively wet the substrate, has excellent leveling, and contains a large amount of high activity in the resin The unsaturated double bonds of the unsaturated double bonds, through the initiation of benzoyl peroxide, undergo free radical polymerization, and all of them are quickly solidified to form a macromolecular network structure, ensuring ...

Embodiment 2

[0028] refer to figure 1 , an anti-yellowing zero VOC quick-drying glossy clear finish paint, including main paint and curing agent, the main paint and curing agent are composed of a ratio of 100:5 by mass, wherein the curing agent is benzoyl peroxide , the main paint is composed of the following components by mass percentage: 98.5% polymethyl methacrylate resin, 0.9% defoamer, 0.6% leveling agent, and the solid content of the yellowing-resistant zero-VOC quick-drying bright clear topcoat is 100% %, the polymethyl methacrylate resin is Degaroute 465 resin, the defoamer is a modified siloxane type defoamer suitable for solvent-free coating systems; the leveling agent is composed of polyether modified silicone leveling agent and fluorine The modified polyacrylic acid leveling agent is mixed according to the mass ratio of 1:2.

[0029] In order to better demonstrate the process of the preparation method of the anti-yellowing zero-VOC quick-drying glossy clear topcoat, this examp...

Embodiment 3

[0033] refer to figure 1 , an anti-yellowing zero VOC quick-drying glossy clear finish paint, including main paint and curing agent, the main paint and curing agent are composed of a ratio of 100:5 by mass, wherein the curing agent is benzoyl peroxide , the main paint is composed of the following components by mass percentage: 99% polymethyl methacrylate resin, 0.6% defoamer, 0.4% leveling agent, and the solid content of the yellowing-resistant zero-VOC quick-drying bright clear topcoat is 100% %, the polymethyl methacrylate resin is Degaroute 465 resin, the defoamer is a modified siloxane type defoamer suitable for solvent-free coating systems; the leveling agent is composed of polyether modified silicone leveling agent and fluorine The modified polyacrylic acid leveling agent is mixed according to the mass ratio of 1:2.

[0034]In order to better demonstrate the process of the preparation method of the anti-yellowing zero-VOC quick-drying glossy clear topcoat, this example ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com