Resin composition, production method of same and molded product

A technology of resin composition and copolymer, which is applied in the field of resin composition, can solve the problems of inhibiting fluidity, reducing etc., and achieve the effect of excellent flame retardancy and excellent impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

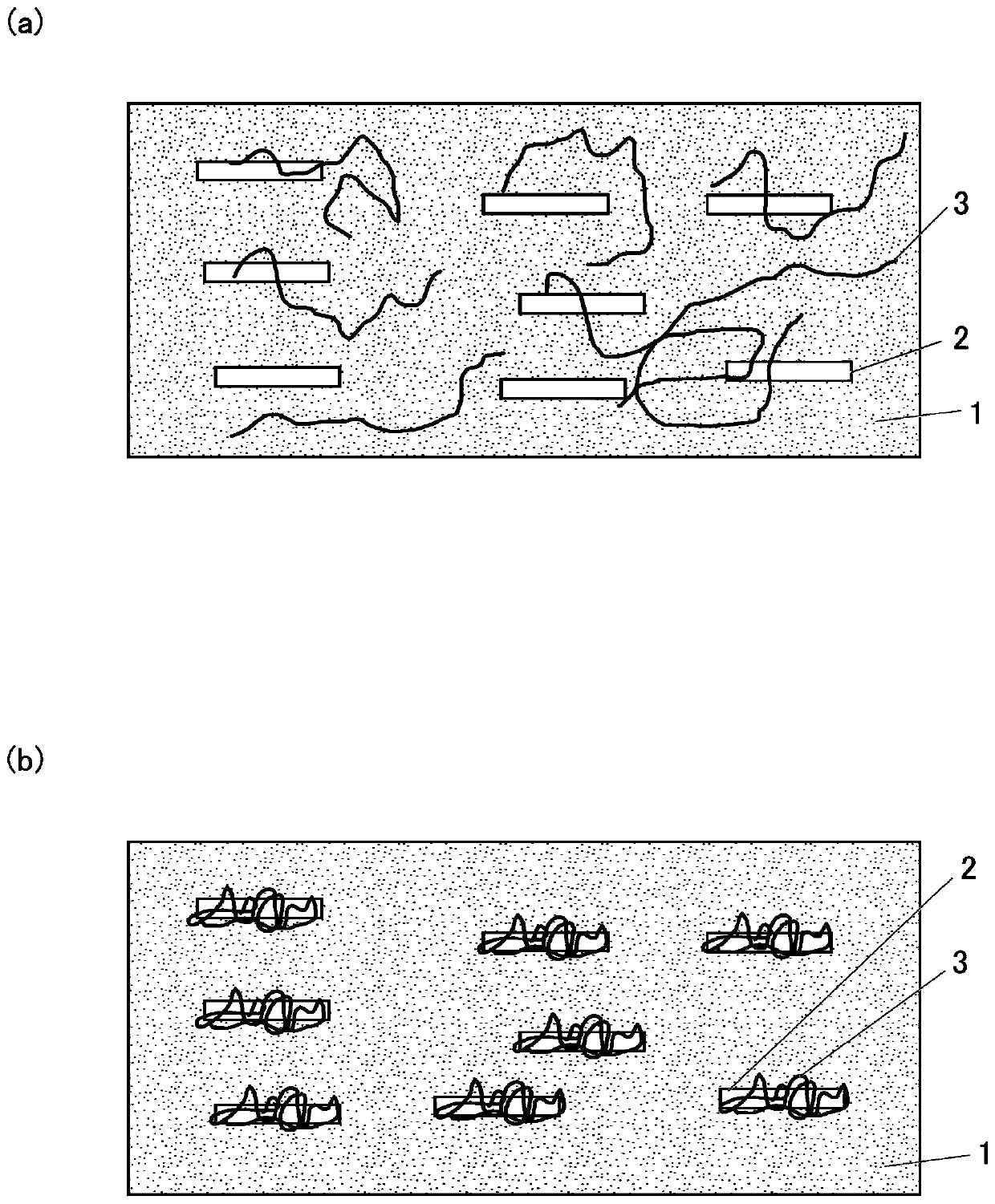

Image

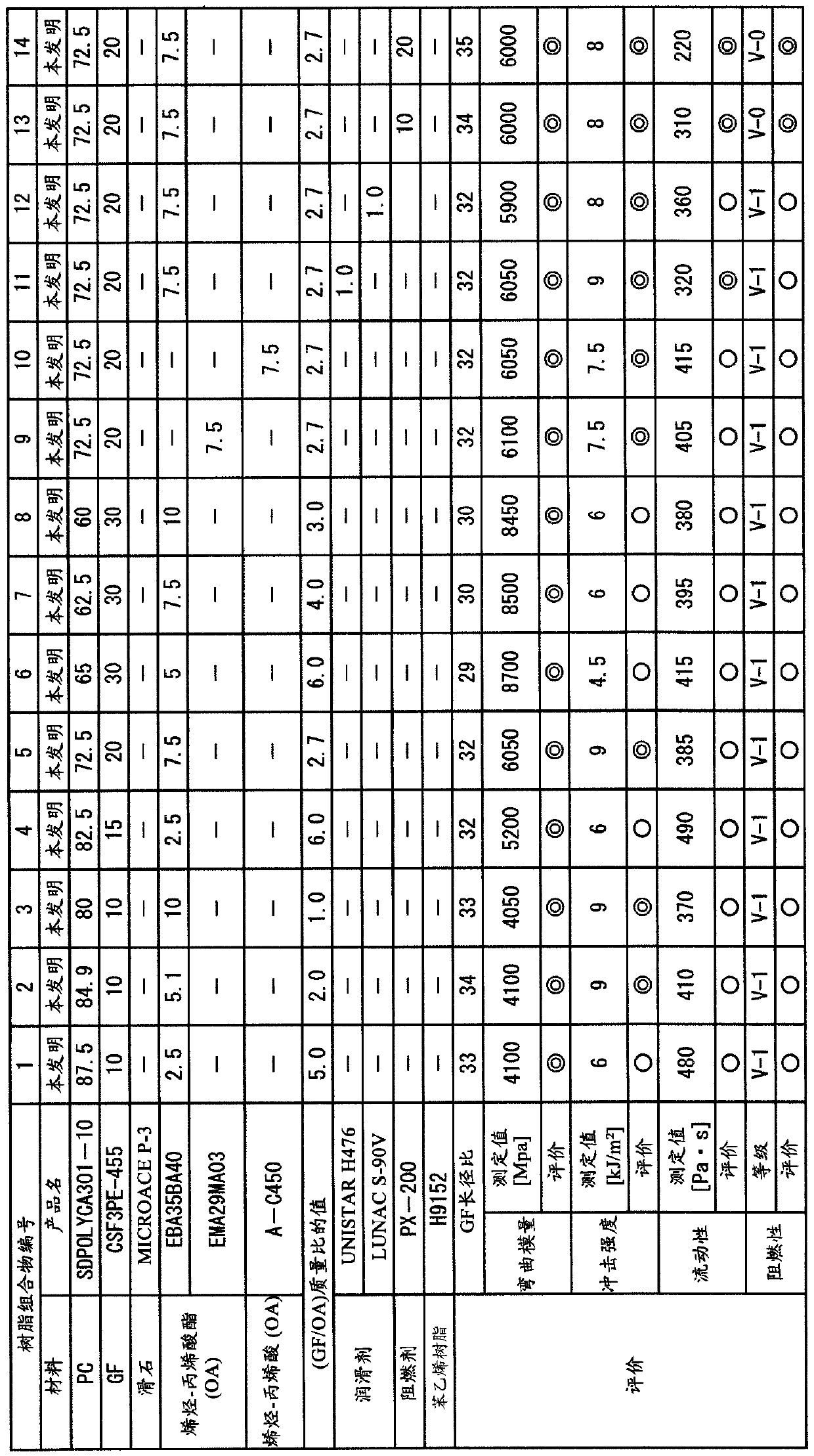

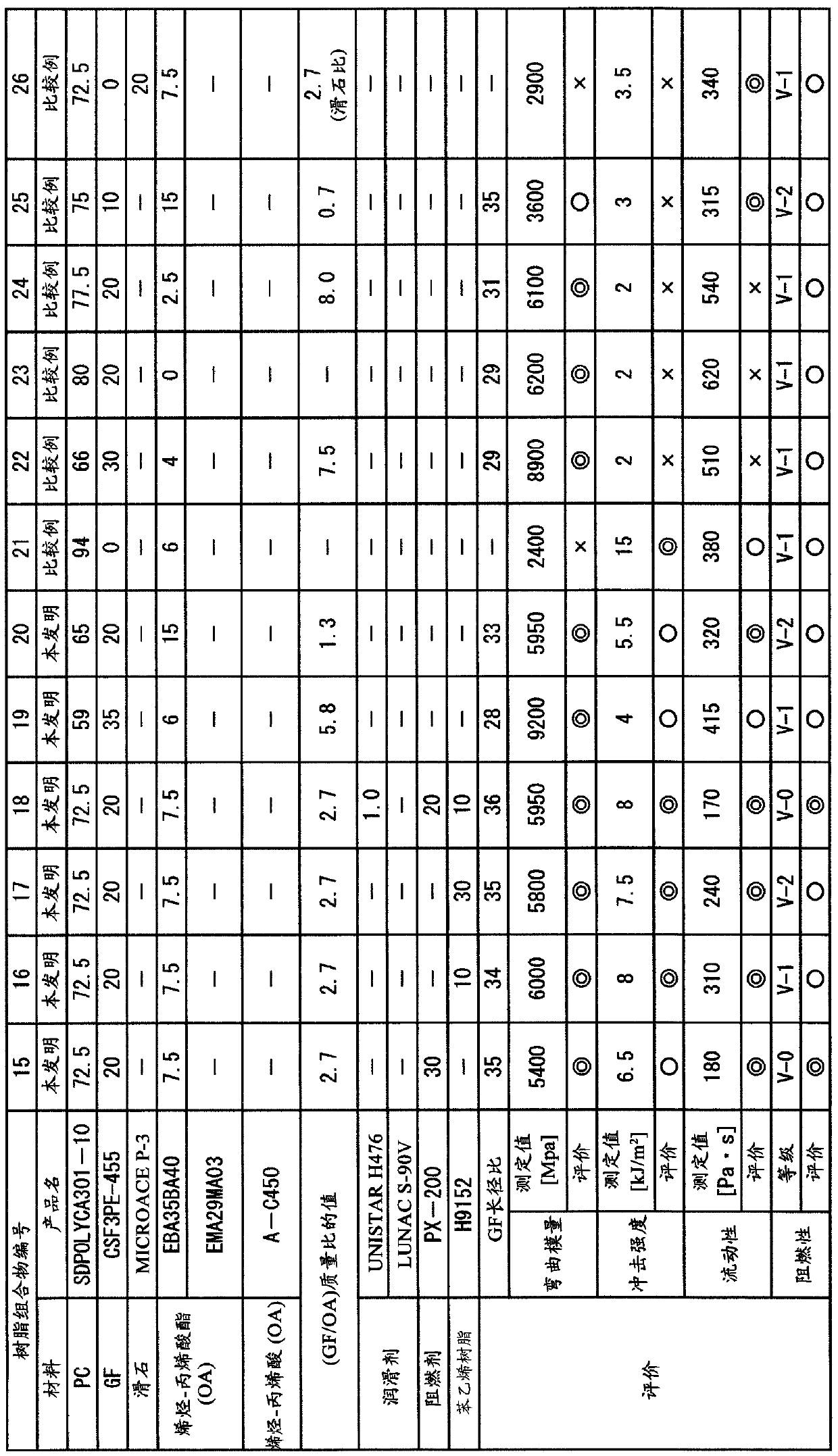

Examples

Embodiment 1

[0144] A resin composition was prepared using the following materials.

[0145] Polycarbonate (PC): SD POLYCA 301-10 (Sumika POLYCARBONATE Co., Ltd.)

[0146] Glass fiber (GF): CSF 3 PE-455 (Nitto Bosho Co., Ltd.)

[0147] Talc: MICROACE P-3 (Japan Talc Industry Co., Ltd.)

[0148] Olefin-acrylate copolymer: LOTRYL EBA 35BA40 (ethylene-butyl acrylate copolymer Arkema)

[0149] Olefin-acrylic acid copolymer: LOTRYL EMA 29BA03 (ethylene-methyl acrylate copolymer, Arkema Corporation)

[0150] Olefin-acrylic acid copolymer: A-C540 (manufactured by ethylene-acrylic acid copolymer Honeywell)

[0151] Flame retardant: PX-200 which is a condensed phosphoric acid compound (Daihachi Chemical Co., Ltd.)

[0152] Lubricant: LUNAC S-90V (stearic acid Kao Corporation)

[0153] UNISTAR H476 (Pentaerythritol Tetrastearate, NOF Corporation)

[0154] Styrenic resin: PSJ-polystyrene H9152 (PS JAPAN Co., Ltd.)

[0155]

[0156] The polycarbonate (PC) of 87.5 mass parts and the ethylene-b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com