A kind of activator and preparation method of copper smelting waste slag applied in concrete

A concrete and copper smelting technology, which is applied in the direction of solid waste management, sustainable waste treatment, climate sustainability, etc., can solve the problem that solid waste cannot be disposed of in a friendly and effective manner, and achieves easy equipment automation, high production efficiency, improved and efficiencies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

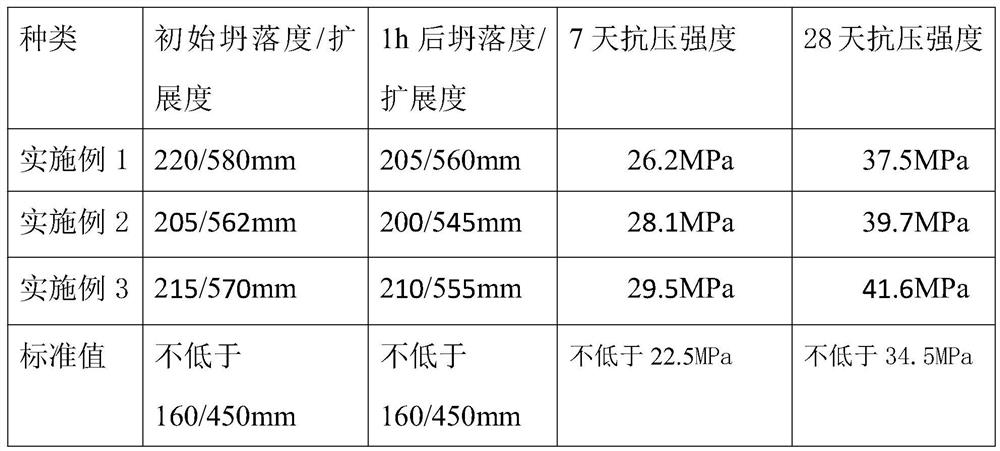

Embodiment 1

[0016] This embodiment provides an activator for using copper smelting waste slag in concrete and a preparation method thereof. The activator comprises polyoxyethylene ether rich in sulfonic acid group and trifluoromethanesulfonate coordinated by alcohol amine with a total content greater than 90%.

[0017] The preparation method of this activator is as follows:

[0018] a. By mass, 100 parts of polyoxyethylene ether monomers with a molecular weight of 1200 were melted in a stainless steel reactor at 58°C for 45 minutes under normal pressure;

[0019] b. Stir at 42 rpm, add 3 parts of calcium methallylsulfonate and 2 parts of sodium 2-acrylamide-2-methylpropanesulfonate to the above hot melt within 15 minutes;

[0020] c. Mix 0.8 parts of sodium persulfate and 0.2 parts of polyethylene glycol 600 in the premix tank with shear stirring to form a polyethylene glycol emulsion, and add the emulsion evenly into the reactor within 2 hours while stirring at 42 rpm ;

[0021] d. We...

Embodiment 2

[0024] This embodiment provides an activator for using copper smelting waste slag in concrete and a preparation method thereof. The activator comprises polyoxyethylene ether rich in sulfonic acid group and trifluoromethanesulfonate coordinated by alcohol amine with a total content greater than 90%.

[0025] The preparation method of this activator is as follows:

[0026] a. By mass, 100 parts of polyoxyethylene ether monomers with a molecular weight of 2400 were melted in a ceramic reactor at 65°C for 60 minutes under normal pressure;

[0027] b. Stir at a speed of 51 rpm, add 3 parts of calcium methallylsulfonate and 3 parts of sodium 2-acrylamide-2-methylpropanesulfonate to the above hot melt within 30 minutes;

[0028] c. Mix 1.2 parts of sodium persulfate and 0.3 parts of polyethylene glycol 200 in the premix tank with shearing and stirring to form a polyethylene glycol emulsion, and add the emulsion evenly into the reactor within 3 hours under stirring at 51rpm ;

[00...

Embodiment 3

[0032] This embodiment provides an activator for using copper smelting waste slag in concrete and a preparation method thereof. The activator comprises polyoxyethylene ether rich in sulfonic acid group and trifluoromethanesulfonate coordinated by alcohol amine with a total content greater than 90%.

[0033] The preparation method of this activator is as follows:

[0034] a. By mass, 100 parts of polyoxyethylene ether monomers with a molecular weight of 2200 were melted in a ceramic reactor at 70°C for 90 minutes under normal pressure;

[0035] b. Stir at a speed of 60 rpm, add 5 parts of calcium methallylsulfonate and 5 parts of sodium 2-acrylamide-2-methylpropanesulfonate to the above hot melt within 20 minutes;

[0036] c. Mix 1.0 part of sodium persulfate and 0.2 part of polyethylene glycol 800 in the premix tank with shear stirring to form a polyethylene glycol emulsion, and add the emulsion evenly into the reactor within 3.5 hours under stirring at 60 rpm ;

[0037] d....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com