Non-metal doped metal oxide denitration catalyst with strong sulfur tolerance and preparation method thereof

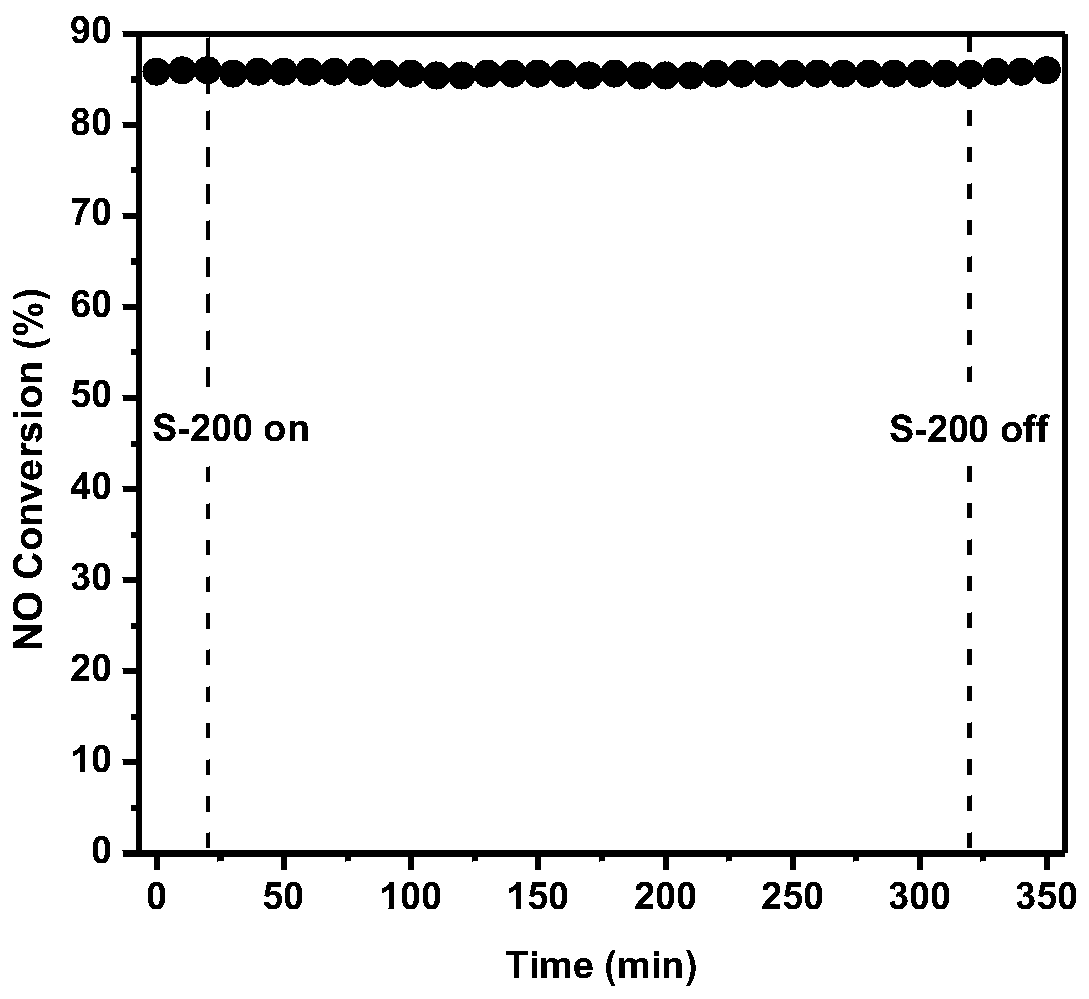

A denitration catalyst and non-metallic technology, applied in the field of metal oxide denitration catalyst and its preparation, can solve the problems of catalyst poisoning and deactivation, and achieve the effects of excellent medium and high temperature activity, simple preparation method, and excellent cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033]In this embodiment, a method for preparing a non-metal-doped metal oxide denitration catalyst with strong sulfur resistance comprises the following steps:

[0034] a. Dissolve 5mL of tetraisopropyl titanate in 50mL of isopropanol, and keep stirring for 10min (solution A);

[0035] b. Weigh a certain amount of thiourea (atomic ratio: S / Ti=1 / 100-1 / 5) and ultrasonically dissolve it in 25 mL of isopropanol, and add 1.5 mL of ionized water and 0.15 mL of nitric acid (solution B) ;

[0036] c. Add solution B dropwise to solution A, keep stirring for 3 hours to obtain a sol, and leave it to age overnight to obtain a gel;

[0037] d. Place the obtained gel in an oil bath at 65°C, dry it for 24 hours, grind the obtained product, put it in a muffle furnace, raise the temperature to 500°C at 5°C / min, and then keep it at 500°C for 3 hours to obtain non-metallic doping metal oxide carrier;

[0038] e. Weigh a certain amount of manganese nitrate (1-10wt%) and dissolve it in an appr...

Embodiment 2

[0042] This embodiment is basically the same as Embodiment 1, and the special features are:

[0043] In this embodiment, a method for preparing a non-metal-doped metal oxide denitration catalyst with strong sulfur resistance comprises the following steps:

[0044] a. Dissolve 5mL of tetraisopropyl titanate in 50mL of isopropanol, and keep stirring for 10min (solution A);

[0045] b. Weigh a certain amount of thiourea (atomic ratio: S / Ti=1 / 100-1 / 5) and ultrasonically dissolve it in 25 mL of isopropanol, and add 1.5 mL of ionized water and 0.15 mL of nitric acid (solution B) ;

[0046] c. Add solution B dropwise to solution A, keep stirring for 3 hours to obtain a sol, and leave it to age overnight to obtain a gel;

[0047] d. Place the obtained gel in an oil bath at 65°C, dry it for 24 hours, grind the obtained product, put it in a muffle furnace, raise the temperature to 500°C at 5°C / min, and then keep it at 500°C for 3 hours to obtain non-metallic doping metal oxide carrie...

Embodiment 3

[0052] This embodiment is basically the same as the previous embodiment, and the special features are:

[0053] In this embodiment, a method for preparing a non-metal-doped metal oxide denitration catalyst with strong sulfur resistance comprises the following steps:

[0054] a. Dissolve 5mL of tetraisopropyl titanate in 50mL of isopropanol, and keep stirring for 10min (solution A);

[0055] b. Weigh a certain amount of thiourea (atomic ratio: S / Ti=1 / 100-1 / 5) and ultrasonically dissolve it in 25 mL of isopropanol, and add 1.5 mL of ionized water and 0.15 mL of nitric acid (solution B) ;

[0056] c. Add solution B dropwise to solution A, keep stirring for 3 hours to obtain a sol, and leave it to age overnight to obtain a gel;

[0057] d. Place the obtained gel in an oil bath at 65°C, dry it for 24 hours, grind the obtained product, put it in a muffle furnace, raise the temperature to 500°C at 5°C / min, and then keep it at 500°C for 3 hours to obtain non-metallic doping metal o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com