Vertical adsorber and gas purification and adsorption system and method

An adsorber and vertical technology, which is applied in the field of vertical adsorbers and gas purification adsorption systems, can solve the problems to be further improved, and achieve the effects of improving adsorption efficiency and purification effect, ensuring adsorption and purification effect, and having a simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

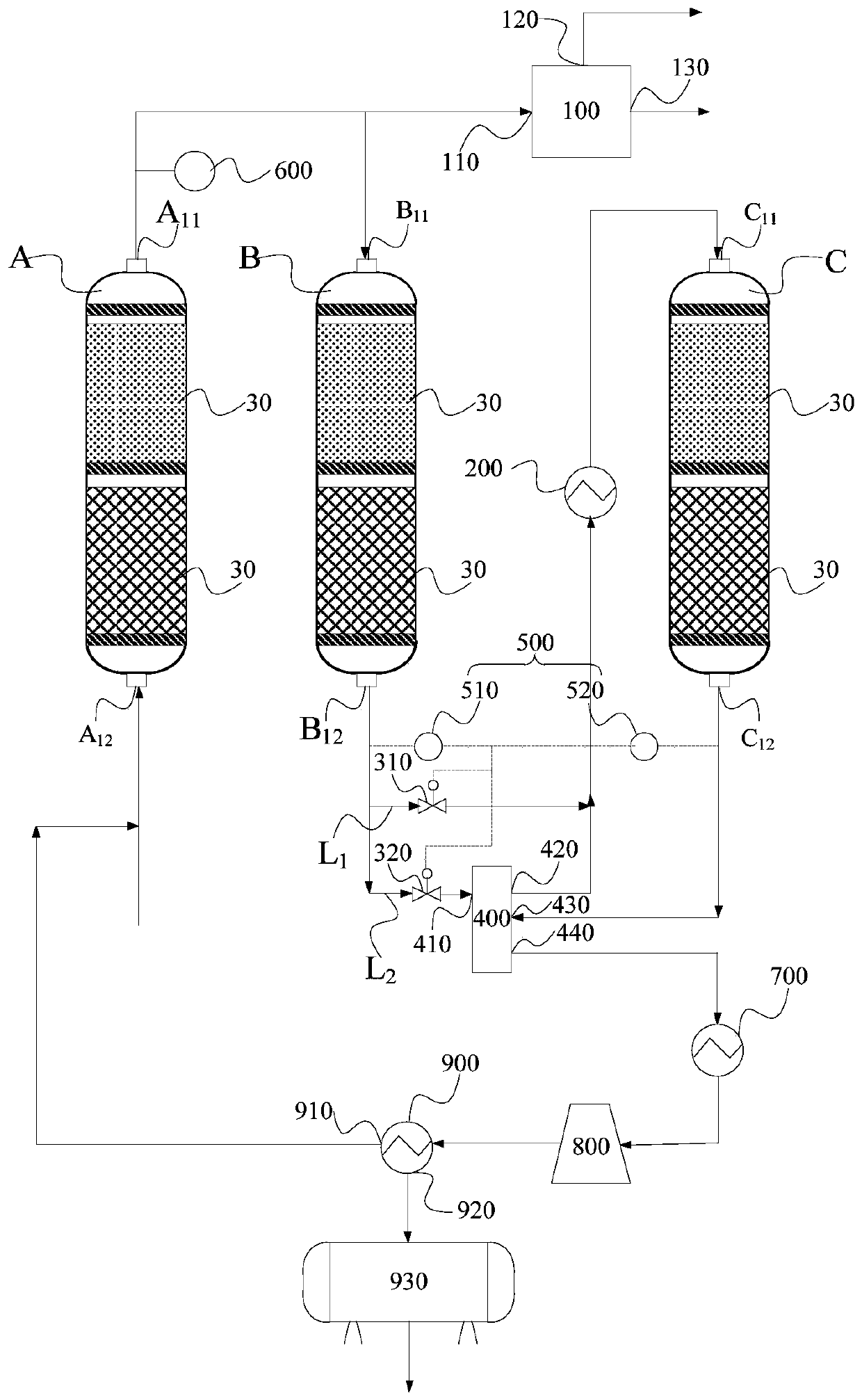

[0075] In this implementation, high-pressure and low-temperature hydrogen containing trace impurities (silicon tetrachloride, trichlorosilane, dichlorodihydrosilane, hydrogen chloride, boride, phosphide) is passed into the adsorber A in the adsorption state to adsorb and separate impurities. Operation, high-pressure low-temperature high-purity hydrogen products can be obtained after adsorption. At the same time, the condensate product and the tail gas rich in boron and phosphorus that need to be discharged are obtained.

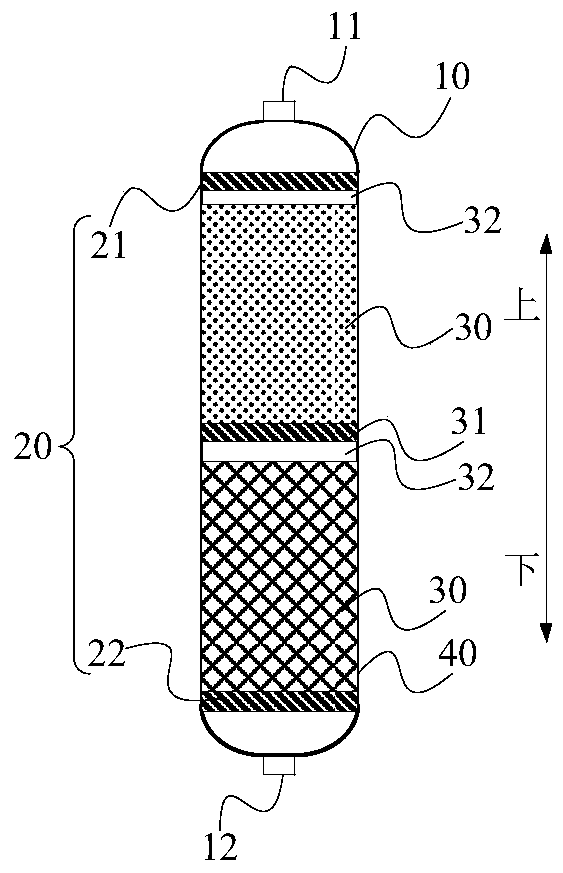

[0076] In this example, coconut shell activated carbon adsorbent layers were used in adsorbers A / B / C. Molecular sieve adsorbents are used in boron and phosphorus removal devices. refer to figure 2 , the specific conditions of this embodiment are as follows:

[0077] (1) High-pressure and low-temperature hydrogen raw material S1 (-10°C, 14barg) containing trace impurities (silicon tetrachloride, trichlorosilane, dichlorodihydrosilane, hydrogen chloride, bo...

Embodiment 2

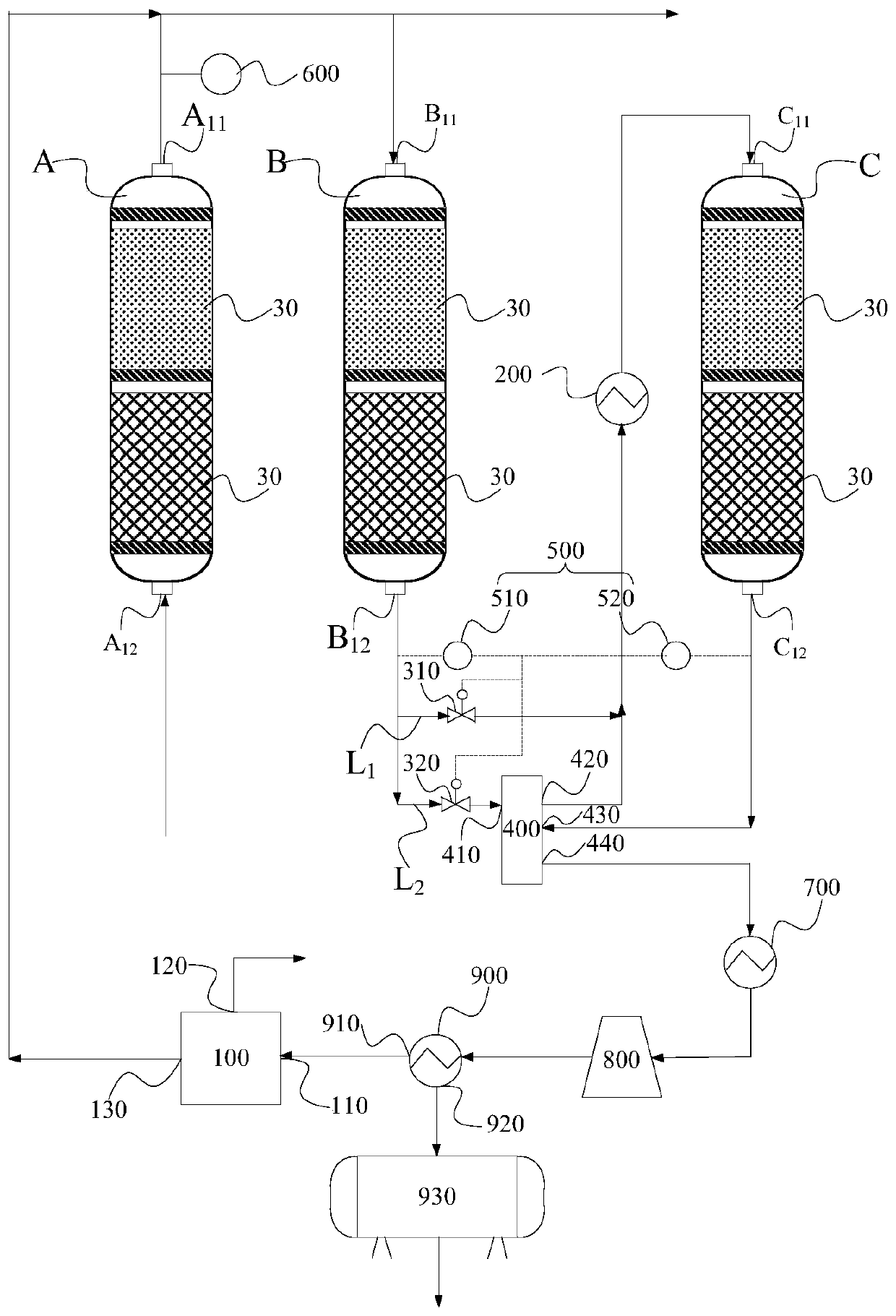

[0089] In this implementation, high-pressure and low-temperature hydrogen containing trace impurities (silicon tetrachloride, trichlorosilane, dichlorodihydrosilane, hydrogen chloride, boride, phosphide) is passed into the adsorber A in the adsorption state to adsorb and separate impurities. Operation, high-pressure low-temperature high-purity hydrogen products can be obtained after adsorption. At the same time, the condensate product and the tail gas rich in boron and phosphorus that need to be discharged can be obtained.

[0090] In this embodiment, the upper adsorbent layer in the adsorber A / B / C uses molecular sieve adsorbent, and the lower adsorbent layer uses coconut shell activated carbon adsorbent. In the boron and phosphorus removal device, activated carbon adsorbent and molecular sieve adsorbent are used in layers. refer to image 3, the specific conditions of this embodiment are as follows:

[0091] (1) High-pressure and low-temperature hydrogen raw material S1 (-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com