Paranasal sinus tube stent and preparation method thereof

A technology for tube stents and sinus tubes, applied in the field of sinus tube stents and their preparation, can solve the problems of difficult to adjust the size in time, the degradation cycle is not synchronized with the tissue healing cycle, and the welding edge is broken.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

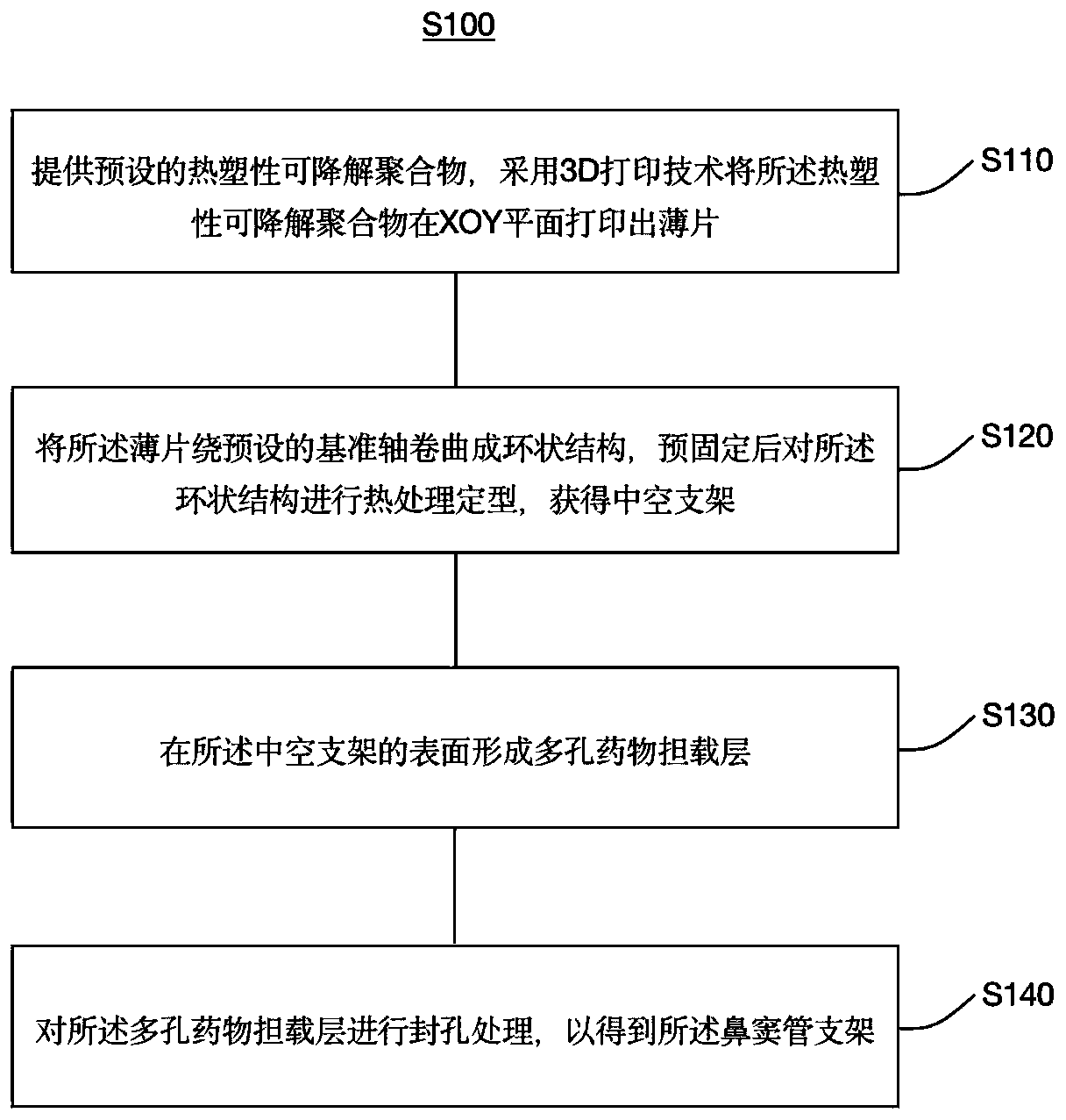

[0043] Such as figure 1 As shown, the first aspect of the present invention provides a method for preparing a sinus tube stent S100, which specifically includes the following steps S110-S140:

[0044] S110. Provide preset thermoplastic degradable polymers, and use 3D printing technology to print thin sheets of thermoplastic degradable polymers on the XOY plane.

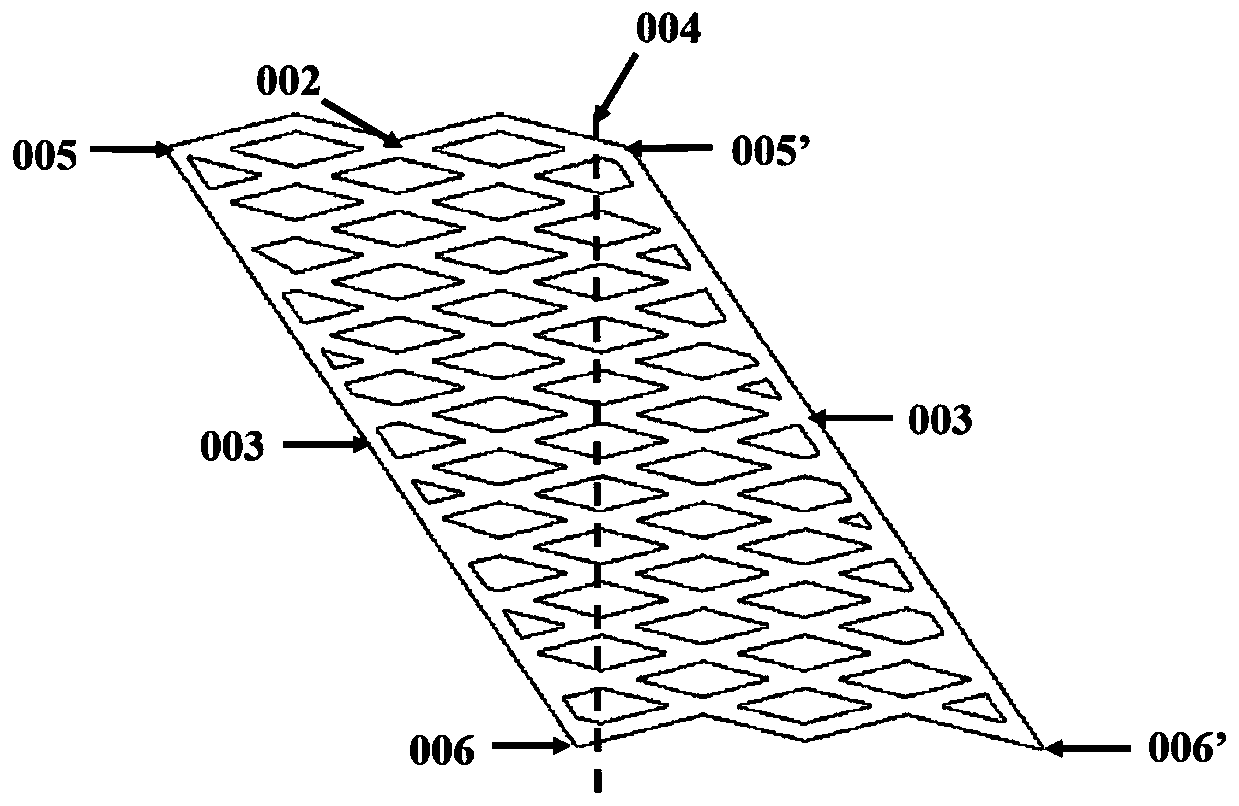

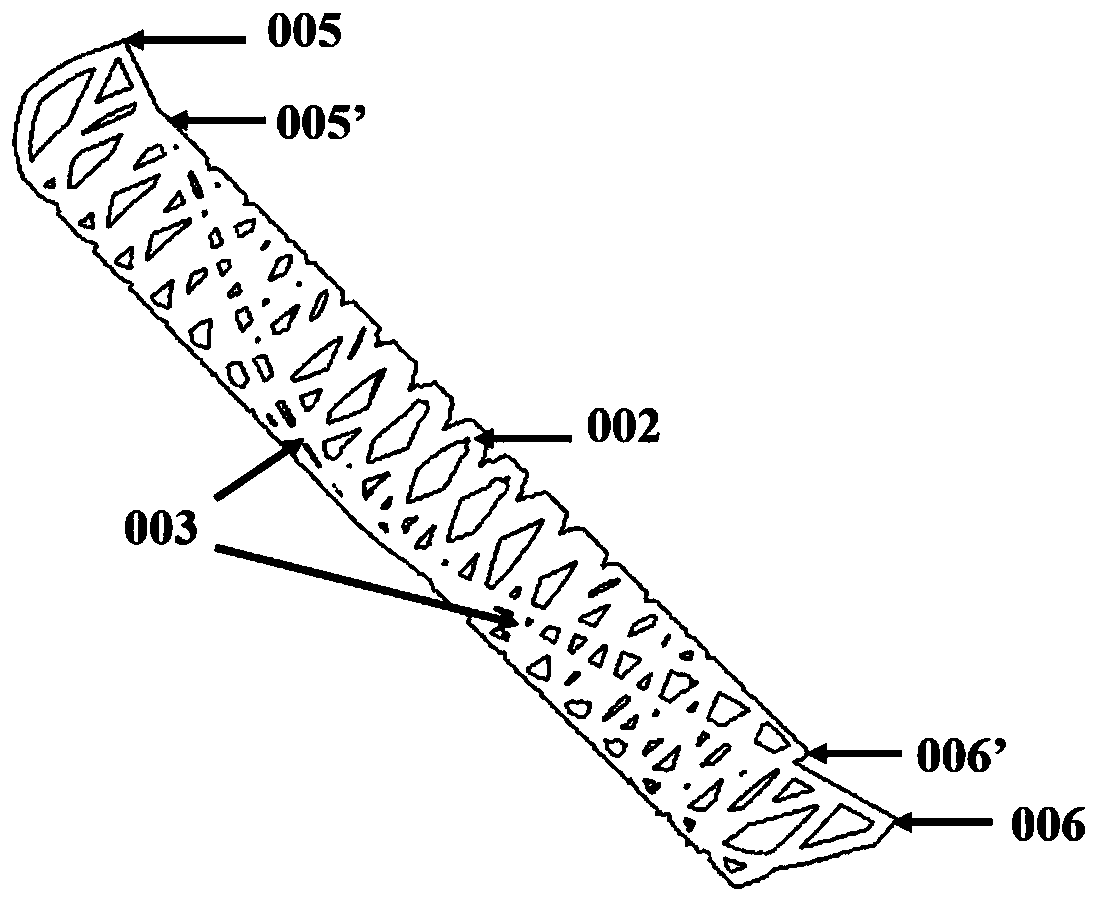

[0045] In view of the fact that the diameter of the stent prepared by the current 3D printing is not easy to change, and the wall thickness of the printed stent is too thick and inelastic, this embodiment uses a fused deposition 3D printer to print a thin sheet of thermoplastic degradable polymer on the XOY plane. The wall thickness is thinner and the diameter is controllable. Exemplary, combined with figure 2 As shown, in this embodiment, the sheet is configured as a parallelogram sheet, the sheet has a length ranging from 10 mm to 20 mm, a width ranging from 20 mm to 30 mm, and a thickness ranging from 0.1 mm to ...

Embodiment 1

[0070] The preparation method of sinus tube stent in this example comprises the following steps:

[0071] S1. Use 3D modeling software to build the side structure model of the bracket, and export the file format as .stl file, import it into the fused deposition 3D printer, and use polycaprolactone (Mv=40,000, PCL) as raw material to print patterns and shapes Unfold the structural sheet model for the sides of the parallelogram, i.e. print out the sheet. Wherein, the specific parameters of the side structure of the parallelogram sheet printed in this embodiment are as follows: length L=10.0 mm, width W=20 mm, sheet thickness t=0.1 mm.

[0072]S2, the parallelogram sheet obtained in step S1 according to the preset direction (refer to figure 2 The center line 004) is curled around a thin copper rod with a diameter of 3.0mm, and the two ends of the welding (reference figure 2 003) and pre-fixed with fine copper wire in the middle, put it in a vacuum drying oven at 40°C for the ...

Embodiment 2

[0079] The preparation method of sinus tube stent in this example comprises the following steps:

[0080] S1. Use 3D modeling software to build the side structure model of the bracket, and export the file format as .stl file, import it into the fused deposition 3D printer, and use polylactic acid glycolic acid (Mv=80,000, PLGA) as raw material to print patterns and shapes Unfold the structural sheet model for the sides of the parallelogram, i.e. print out the sheet. Wherein, the specific parameters of the side structure of the parallelogram sheet printed in this embodiment are as follows: length L=13.0 mm, width W=25.0 mm, sheet thickness t=0.2 mm.

[0081] S2, the parallelogram sheet obtained in step S1 according to the preset direction (refer to figure 2 The center line 004) is curled around a thin copper rod with a diameter of 4.0mm, and the two ends of the welding (reference figure 2 003) and pre-fixed with fine copper wire in the middle, put it in a vacuum drying oven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com