A peo-pmma solid electrolyte membrane

A technology of solid electrolyte membrane and electrolyte, which is applied in the direction of solid electrolyte, electrolyte, non-aqueous electrolyte, etc., can solve the problems of poor contact, affecting safety and stability, and the mechanical properties of the electrolyte cannot meet the requirements of positive and negative materials at the same time, so as to achieve stability The effect of good performance, excellent mechanical properties and electrical conductivity properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0052] Specific embodiments: a PEO-PMMA solid electrolyte membrane is prepared according to the following method steps:

[0053] In step 1, the raw materials PEO, PMMA, inorganic lithium salt, plasticizer and inorganic solid particle materials are mixed in liquid phase according to the ratio requirements of the multi-layers to obtain a three-layer casting gel material; step 1 specifically includes:

[0054] Step 1.1, dissolve PEO and PMMA into the corresponding amount of organic solvent respectively, stir until gelatinous and then mix; the organic solvent for dissolving PEO is acetonitrile or DMF solution;

[0055] Step 1.2, the mixed gel was placed at 40°C and stirred for 6 hours;

[0056] Step 1.3, then add inorganic lithium salt, plasticizer and inorganic solid particle material, then grind in the glove box, and then stir it with magnetic force until it is completely decomposed, the solution is uniform and consistent gel, and the gel material for casting is obtained .

[...

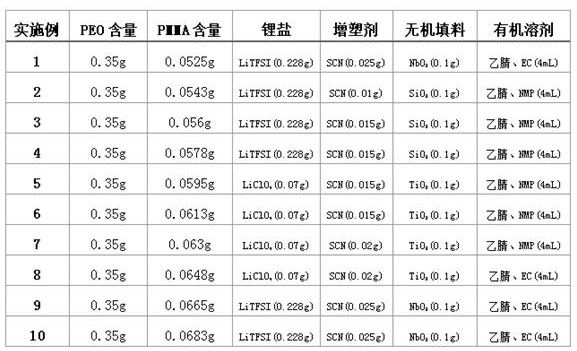

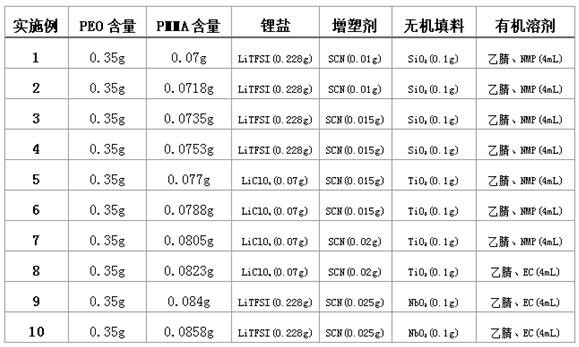

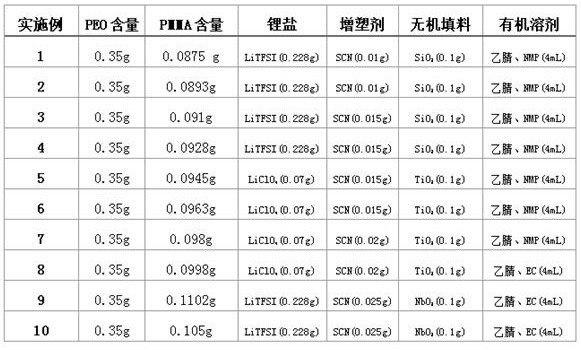

experiment example 1-10

[0062] Experimental example 1-10: On the basis of meeting the requirements of each step of the above specific implementation method, the experimental example 1-10 was obtained by using the following specific implementation steps and the 10 groups of specific parameter ranges defined in the table.

[0063] At room temperature, weigh three parts of PEO with a fixed mass (see the table for details) and three parts of PMMA with different masses, mix them in pairs and put them into three 10mL glass bottles, and then add a certain volume of acetonitrile solution and organic Stir the solution, stir each into a uniform and transparent colloid and mix them, then place them at 40°C and stir for 6 hours, then add a fixed mass of plasticizer, lithium salt and inorganic fillers, grind them and stir them magnetically for several hours until the samples are completely After dissolving, a transparent gel solution is obtained, and then the prepared 3 bottles of PEO-PMMA transparent gel solution a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com