Schottky back gate metal oxide semiconductor field effect phototransistor with sunlight blind area

A technology of oxide semiconductors and phototransistors, applied in semiconductor devices, circuits, electrical components, etc., can solve the problems of device performance degradation, low thermal conductivity, large dark current, etc., to reduce power loss, increase operating frequency, strengthen The effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

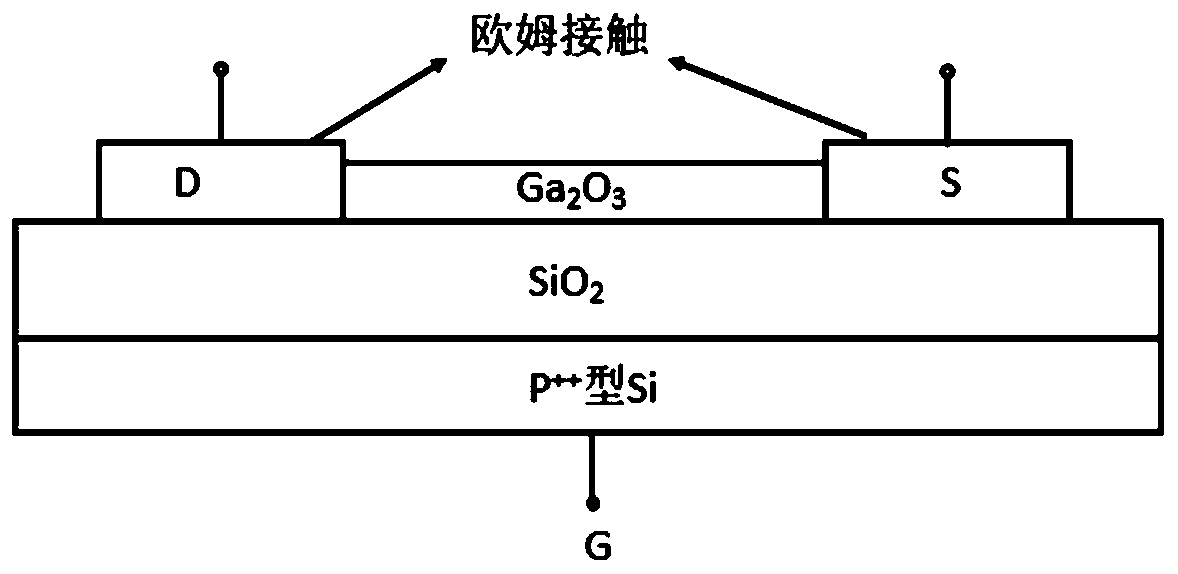

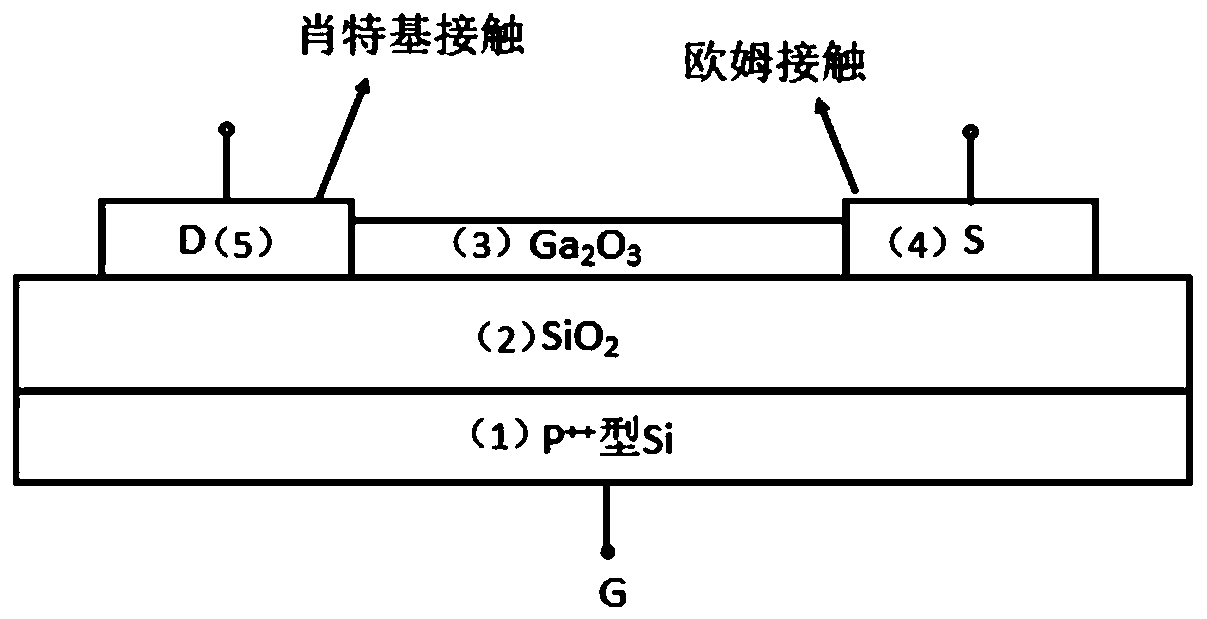

[0034] Embodiment 1: prepare Ga 2 o 3 Schottky contact back gate MOSFET with a film thickness of 100nm.

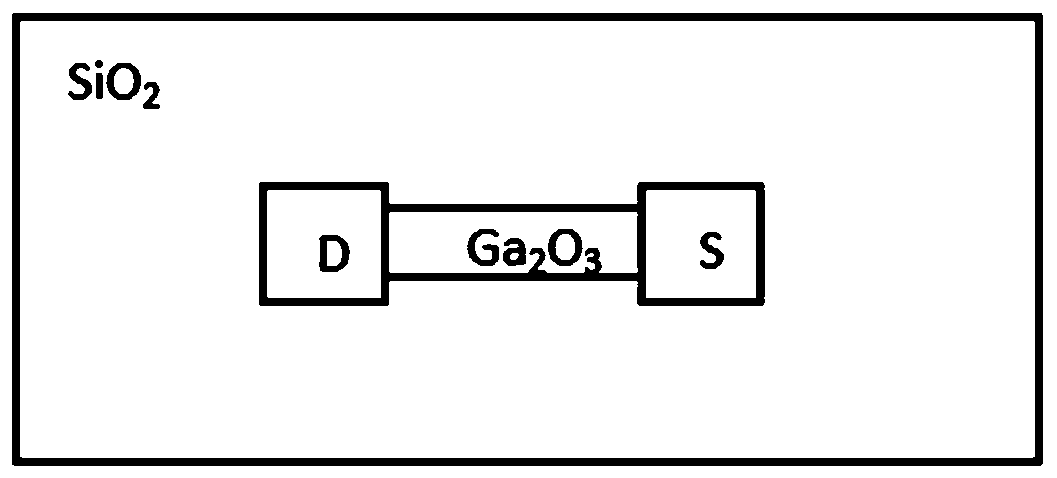

[0035] Step 1, transfer Ga 2 o 3 The thin film forms the channel layer.

[0036] 1.1) Select the back gate oxide substrate, the two sides of which are P++ type Si and SiO respectively 2 Oxide dielectric layer, in which P++ type Si is used as the back gate, with a thickness of 650nm, SiO 2 As a substrate, the thickness is 200nm, such as Figure 4 as shown in (a);

[0037] 1.2) Ga 2 o 3 The material is peeled onto the blue glue along the 100 crystal direction, and the Ga is reduced by repeated tearing 2 o 3 The thickness of Ga 2 o 3 Thin films were transferred onto the above substrates, such as Figure 4 (b);

[0038] 1.3) After the transfer is successful, place the transferred sample in acetone, absolute ethanol, and deionized water for 10 minutes, and then dry it with a nitrogen gun. The ultrasonic cleaning power should be adjusted to ensure that Ga 2 o 3 T...

Embodiment 2

[0052] Embodiment 2: preparation of Ga 2 o 3 Schottky contact back gate MOSFET with a film thickness of 200nm.

[0053] Step 1, transfer Ga 2 o 3 The thin film forms the conductive layer.

[0054] 1a) Select the back gate oxide substrate, the two sides of which are P++ type Si and SiO respectively 2 Oxide dielectric layer, in which P++ type Si is used as the back gate, with a thickness of 800nm, SiO 2 As a substrate, the thickness is 250nm, such as Figure 4 (a);

[0055] 1b) Ga 2 o 3 The material is peeled onto the blue glue along the 100 crystal direction, and the Ga is reduced by repeated tearing 2 o 3 The thickness of Ga 2 o 3 Thin films were transferred onto the above substrates, such as Figure 4 as shown in (b);

[0056] 1c) After the transfer is successful, place the transferred sample in acetone, absolute ethanol, and deionized water for 10 minutes, and then dry it with a nitrogen gun. The ultrasonic cleaning power should be adjusted to ensure that Ga 2...

Embodiment 3

[0070] Embodiment 3: prepare Ga 2 o 3 Schottky contact back gate MOSFET with a film thickness of 300nm.

[0071] Step A, transfer Ga 2 o 3 thin film forming conductive layer

[0072] A1) Select the back gate oxide substrate, the two sides of which are N++ type Si and SiO respectively 2 Oxide dielectric layer, in which N++ type Si is used as the back gate, with a thickness of 500nm, SiO 2 As a substrate, the thickness is 300nm, such as Figure 4 as shown in (a);

[0073] A2) Ga 2 o 3 The material is peeled onto the blue glue along the 100 crystal direction, and the Ga is reduced by repeated tearing 2 o 3 The thickness of Ga 2 o 3 Thin films were transferred onto the above substrates, such as Figure 4 as shown in (b);

[0074] A3) Adjust the ultrasonic cleaning power, and place the transferred sample in acetone, absolute ethanol, and deionized water for 10 minutes in order to ensure that Ga 2 o 3If the film does not come off, blow it dry with a nitrogen gun.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com