Fire-resistant antibacterial curtain fabric and preparation method thereof

A technology for curtains and fabrics, applied in the field of textile fabrics, can solve the problems of poor antibacterial durability of fabrics, poor flame retardancy and fire resistance of curtain fabrics, etc., and achieve the effects of chemical degradation resistance, excellent antibacterial performance, and good spinnability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1~4

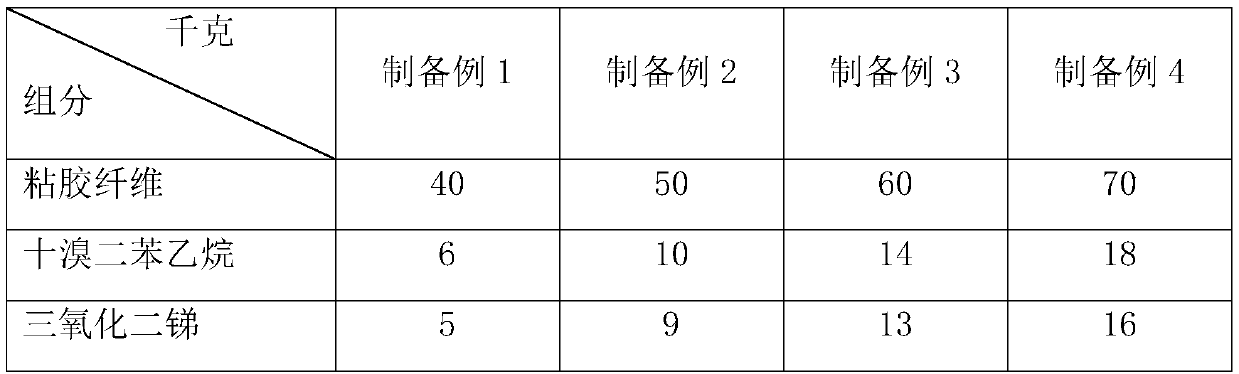

[0039] Raw material ratio of high-strength flame-retardant viscose fiber in Table 1 Preparation Examples 1-4

[0040]

[0041] Preparation method: according to the ratio, the pulp is fed, soaked, squeezed, crushed, aged, yellowed and ground in sequence to obtain the viscose fiber precursor, and then decabromodiphenylethane and antimony trioxide are co-mixed Mixing and grinding into a uniformly dispersed powder, the viscose fiber precursor is post-dissolved, mixed, filtered, defoamed, filtered and short filament spinning to obtain viscose fiber, and at the same time, decabromodiphenylethylene is added in the post-dissolution step alkane and antimony trioxide powder to produce high-strength flame-retardant viscose fiber.

Embodiment 1

[0043] Example 1: A fire-resistant and antibacterial curtain fabric, comprising the following components in parts by weight: 180 parts of stock solution aramid fiber, 80 parts of high-strength flame-retardant viscose fiber in Preparation Example 1, 15 parts of spandex, and 30 parts of antistatic fiber , 12 parts of antibacterial agent, 12 parts of light-resistant agent; Among them, the stock solution aramid fiber is polym-phenylene isophthalamide, the antistatic fiber is metal compound fiber, the antibacterial agent is organosilicon quaternary ammonium salt antibacterial agent, and the light-resistant agent is Titanium dioxide and carboxymethyl cellulose are prepared by blending at a mass ratio of 2:1;

[0044] The preparation method of this refractory antibacterial type curtain cloth comprises the following steps:

[0045] S1. According to the formula, add the full amount of the raw liquid aramid fiber into the twin-screw extruder at a temperature of 560°C, and then add the a...

Embodiment 2

[0049] Example 2: A fire-resistant and antibacterial curtain fabric, including the following components by weight: 200 parts of stock solution aramid fiber, 86 parts of high-strength flame-retardant viscose fiber in Preparation Example 2, 17 parts of spandex, and 35 parts of antistatic fiber , 13 parts of antibacterial agent, 14 parts of light-resistant agent; Among them, the stock solution aramid fiber is polym-phenylene isophthalamide, the antistatic fiber is metal compound fiber, the antibacterial agent is organosilicon quaternary ammonium salt antibacterial agent, and the light-resistant agent is Titanium dioxide and carboxymethyl cellulose are prepared by blending at a mass ratio of 2:1;

[0050] The preparation method of this refractory antibacterial type curtain cloth comprises the following steps:

[0051] S1. According to the formula, add the whole amount of raw liquid aramid fiber into the twin-screw extruder at a temperature of 590°C, and then add antibacterial agen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com