Tantalum target material with preferred orientation, preparation method of tantalum target material and torsion device

A technology of preferential orientation and tantalum target material, which is applied in metal material coating process, ion implantation plating, coating, etc., can solve problems such as uneven target structure, target scrapping, and changing the grain orientation of tantalum ingots. Achieve the effect of realizing preferred orientation, reducing grain size and reducing impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a method for preparing a tantalum target with a preferred orientation, comprising the following steps:

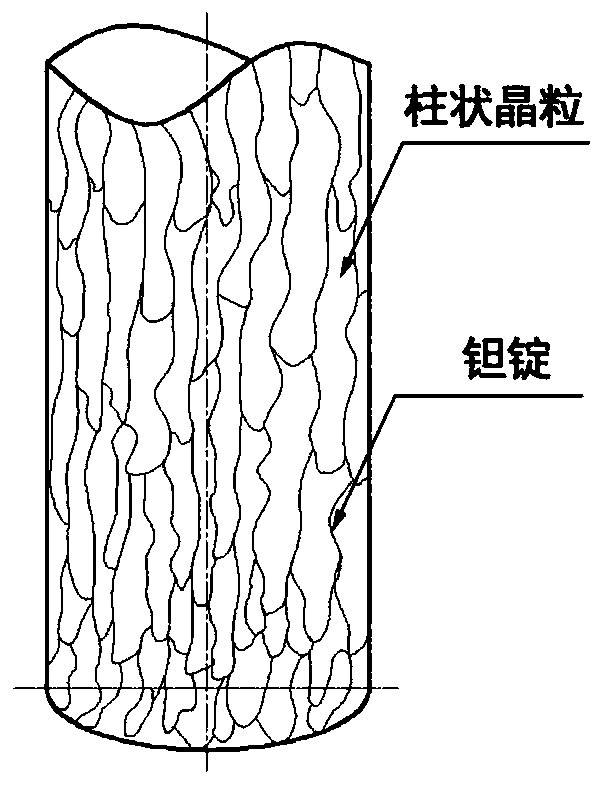

[0027] (1) Pickling, annealing, and cooling the tantalum ingot in sequence to obtain a pretreated tantalum ingot; the tantalum ingot is a cylindrical tantalum ingot;

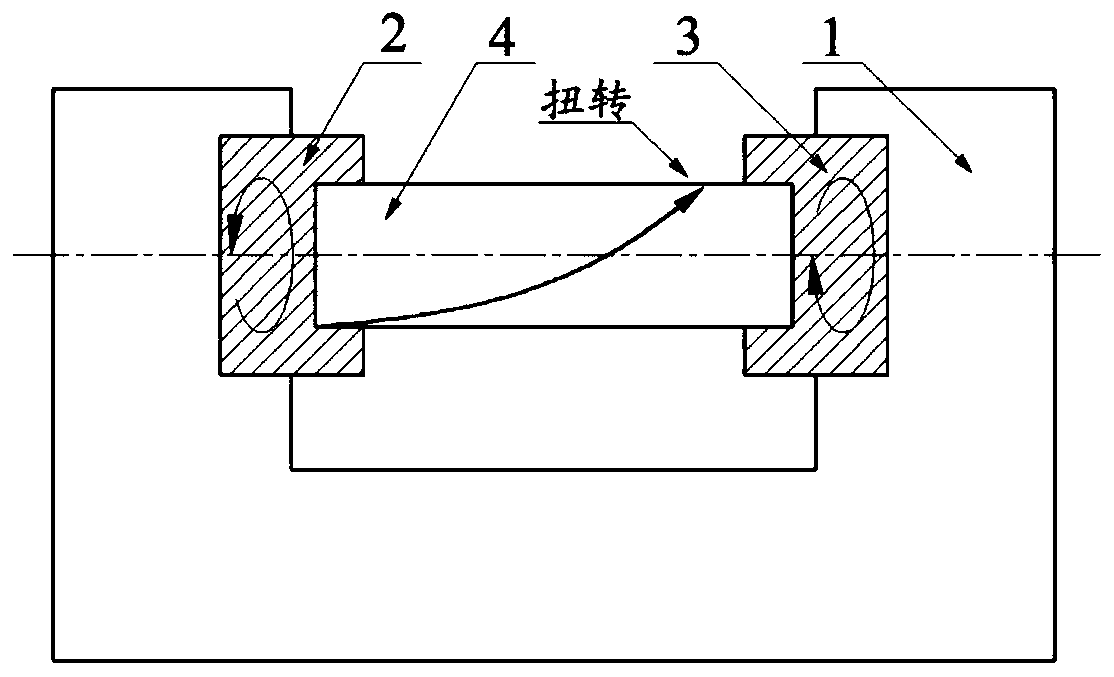

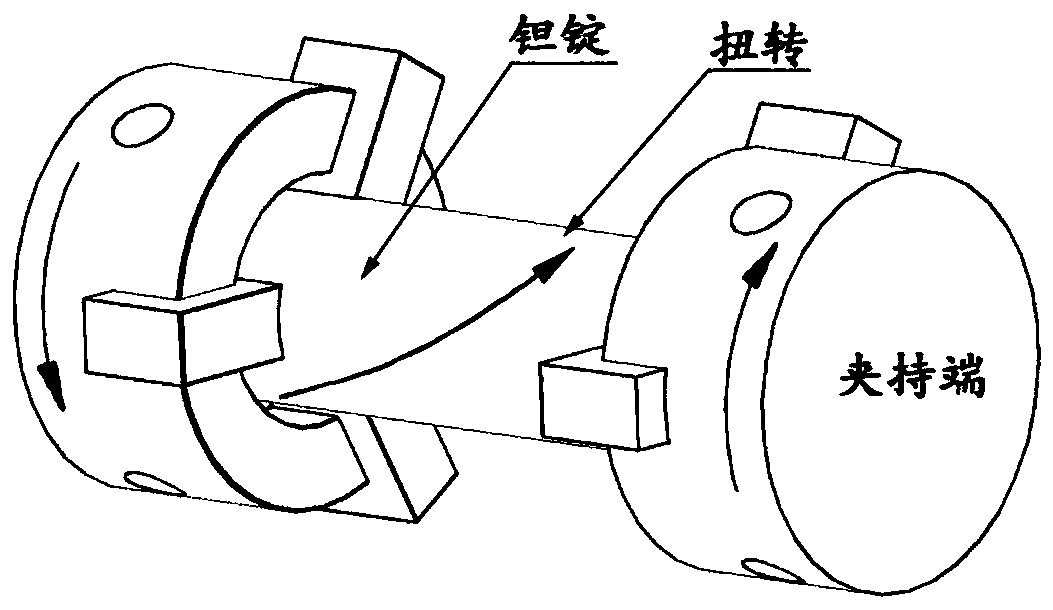

[0028] (2) performing torsion deformation on the pretreated tantalum ingot, the torsion angle of the torsion deformation is greater than or equal to 180°;

[0029] (3) Carry out annealing heat treatment and cooling successively with the tantalum ingot after torsion deformation;

[0030] (4) Repeat steps (2) to (3) 2 to 3 times to obtain a tantalum target body;

[0031] (5) Cut off both ends of the tantalum target blank, and cut the remaining part into sheets to obtain a tantalum target with preferred orientation.

[0032] In the invention, the tantalum ingot is pickled, annealed, heat-treated and cooled in sequence to obtain a pretreated high-purity tantalum ingot. In the pres...

Embodiment 1

[0044] (1) Select high-purity tantalum ingots smelted by electron beams, the total content of alloy elements and impurity elements in the tantalum ingots is not higher than 5%, the diameter is 300 mm, and the length is 600 mm; the tantalum ingots are pickled, and the pickling solution is chemical Pure hydrofluoric acid;

[0045] (2) Perform annealing heat treatment on the pickled tantalum ingot, the annealing temperature is 800°C, the holding time is 30min, and it is cooled with the furnace;

[0046] (3) Clamp the tantalum ingot after annealing heat treatment figure 2 Twisting in the twisting device shown, the twisting method is reverse rotation at both ends, and the rotation angle is 180°;

[0047] (4) Perform annealing heat treatment on the twisted tantalum ingot, the heat treatment temperature is 800°C, the holding time is 30min, and it is cooled with the furnace;

[0048] (5) Repeat steps (3) to (4) twice to obtain a tantalum target body with a preferred orientation;

...

Embodiment 2

[0053] Others are the same as in Embodiment 1, only the torsion angle of step (3) is changed to 360°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com